Description

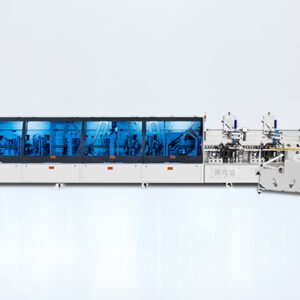

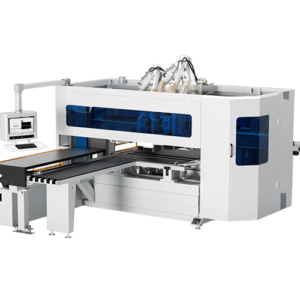

Introducing the Double Guide Rail Edge Banding Machine Swan, the ultimate solution for furniture manufacturers who refuse to compromise on precision. Engineered based on the robust SDE836 platform, the “Swan” edition is distinguished by its heavy-duty construction and superior operational smoothness.

At the core of this machine lies its defining feature: the Double Guide Rail system. Unlike standard edge banders, this machine is built to handle heavy workloads and high feed speeds without the vibration that causes edge imperfections.

Why Choose a Double Guide Rail Edge Banding Machine?

In the competitive world of panel furniture manufacturing, stability is synonymous with quality. The Double Guide Rail Edge Banding Machine architecture offers three distinct advantages over traditional single-rail models:

-

Zero Vibration: The reinforced double rail design anchors the press beam, ensuring the panel remains perfectly flat and immobile during the banding process.

-

Higher Precision: With increased stability, the trimming and corner rounding units can execute cuts with microscopic accuracy.

-

Extended Lifespan: The load is distributed more evenly across the machine frame, reducing wear and tear on mechanical components.

Key Features of the Swan SDE836

The Double Guide Rail Edge Banding Machine Swan is a fully automatic solution equipped with a comprehensive range of stations to take your panel from raw cut to finished product in a single pass.

-

Pre-Milling Unit: Removes burrs and imperfections from the panel edge before gluing, ensuring a seamless invisible joint.

-

Advanced Gluing System: Features a rapid-heating glue pot that ensures consistent adhesive application for tight, water-resistant bonds.

-

Precision End Cutting: Dual saw blades cut the excess edge band at the front and back of the panel with high-speed precision.

-

Rough & Fine Trimming: Removes excess material from the top and bottom edges, creating a smooth, flush finish.

-

Corner Rounding (Profiling): A crucial feature for high-end furniture, this unit rounds the corners of the panel for a soft, professional touch.

-

Scraping Unit: Removes any knife marks left by the trimming cutters (R-scraping) and cleans excess glue (Flat scraping).

-

Buffing Unit: Polishes the edge to restore color and shine to the PVC/ABS material.

Technical Specifications & Performance

-

Keyword Focus: Double Guide Rail Edge Banding Machine

-

Model: Swan (SDE836)

-

Panel Thickness: 10mm – 60mm

-

Edge Tape Thickness: 0.4mm – 3mm

-

Operation: High-speed automatic feed with PLC Touch Screen Control.

-

Application Materials: Ideal for MDF, Plywood, Particle Board, and Solid Wood panels.

Applications

The Double Guide Rail Edge Banding Machine Swan is designed for medium to large-scale furniture factories. It is the perfect workhorse for producing:

-

Custom Kitchen Cabinetry

-

Office Furniture and Desks

-

Modern Wardrobes

-

Commercial Display Units

Elevate Your Production Standards

Don’t let vibration compromise your finish quality. Invest in the Double Guide Rail Edge Banding Machine Swan and experience the difference that structural rigidity makes. Whether you are using high-gloss acrylics or textured wood grains, the Swan SDE836 delivers a flawless edge every time.