Description

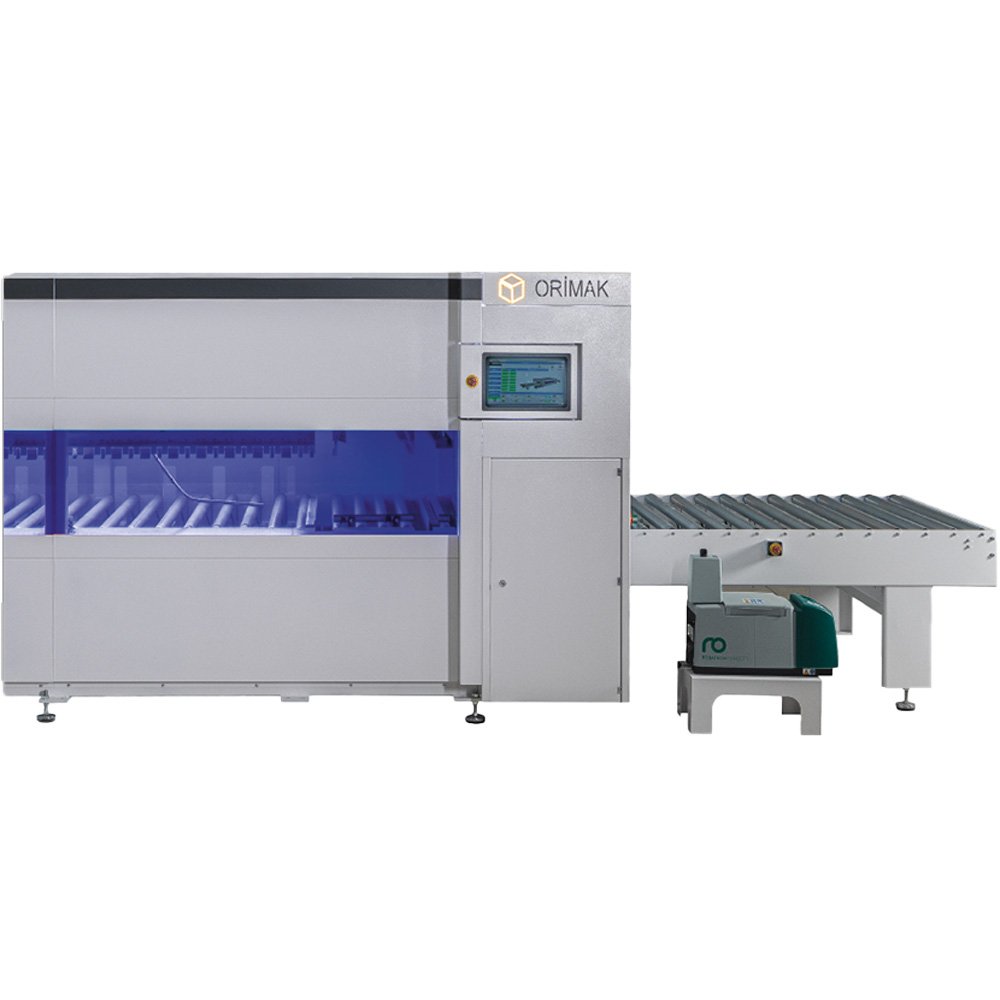

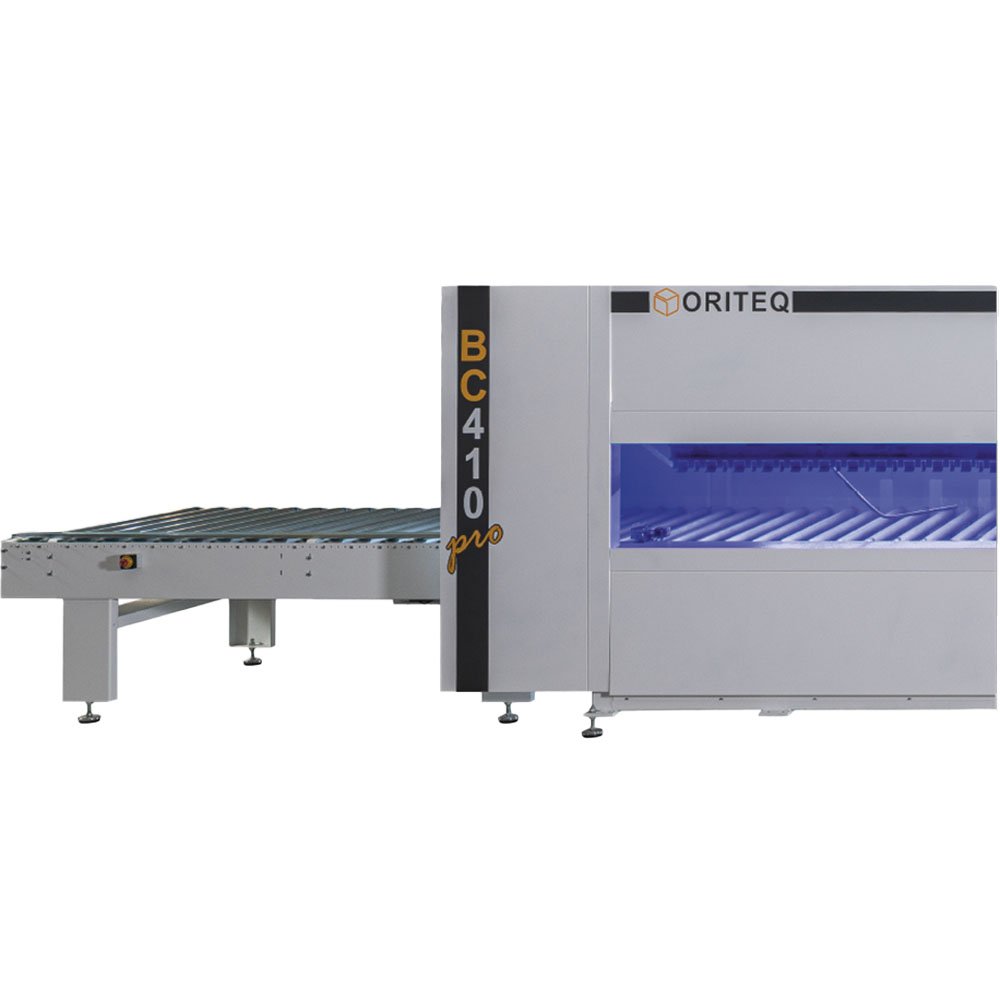

Introducing the ORITEQ BC410 pro Box Closing Machine, a cutting-edge solution for sealing boxes with efficiency, precision, and cost-effectiveness. Designed to handle boxes of the widely used FEFCO 410 type, this machine employs state-of-the-art Hot Melt Technology to securely glue the side covers of filled boxes, ensuring a high-quality finish for diverse packaging applications.

One of the standout features of the ORITEQ BC410 pro Box Closing Machine is its user-friendly design, eliminating the need for manual input of dimensions for different box sizes. Automatic box measurement upon entry streamlines the process, allowing for seamless and quick adjustments to accommodate various package sizes.

The closing mechanisms of the machine operate swiftly and automatically, utilizing Hot Melt Technology to apply adhesive with precision. This not only enhances the quality of box sealing but also contributes to significant cost savings when compared to traditional adhesive tape technology.

The ORITEQ BC410 pro Box Closing Machine offers versatility with different glue spraying options, providing flexibility to meet specific production requirements. Its high-speed production capability ensures impressive productivity, with a batch production rate ranging from 4 to 8 pieces per minute.

With a compact screen structure and integrated vacuum system, the machine optimizes space while maintaining efficient functionality. The technical specifications of the ORITEQ BC410 pro Box Closing Machine include a wide range of box dimensions, accommodating varying lengths, heights, and widths. The machine boasts a maximum box length of 3000 mm, a minimum box height of 30 mm, and a maximum box width of 1250 mm.

Powered by 25 kW and weighing 3500 kg, the ORITEQ BC410 pro Box Closing Machine is a robust and reliable solution for box closing, offering minimal employee involvement and ensuring consistent, high-quality production across different box sizes. Whether handling small batches or large-scale production, this machine stands as a testament to innovation and efficiency in modern packaging technology.

Key Advantages

- Hot Melt Technology: The use of advanced Hot Melt Technology ensures a strong and reliable bond, contributing to a high-quality and secure seal for boxes.

- Automatic Box Measurement: Eliminates the need for manual input of box dimensions, streamlining the production process and facilitating quick adjustments for different box sizes.

- Versatility in Glue Spraying: The machine offers various glue spraying options, providing flexibility to meet specific production requirements and ensuring optimal adhesive application.

- High-Speed Production: With a batch production rate ranging from 4 to 8 pieces per minute, the ORITEQ BC410 pro excels in high-speed production environments, enhancing overall efficiency.

- Cost Savings: The adoption of Hot Melt Technology over traditional adhesive tape technology results in significant cost savings, making it an economically sound choice for box sealing.

- Vacuum System Integration: The integrated vacuum system optimizes functionality, contributing to a smooth and efficient production process.

- Compact Screen Structure: The space-efficient design with a compact screen structure enhances user experience, ensuring ease of operation and saving valuable workspace.

- Wide Range of Box Dimensions: The machine accommodates diverse box sizes, with a maximum box length of 3000 mm, offering flexibility to meet varied packaging needs.

- Minimal Employee Involvement: Designed for minimal manual intervention, the ORITEQ BC410 pro reduces the need for extensive labor, contributing to operational efficiency.

- Robust Construction: With an installed power of 25 kW and a weight of 3500 kg, the machine exhibits a robust build, ensuring durability and reliability in continuous production cycles.

Click here to see all packaging machines or contact your sales representative to get the sales price in Toronto.