Description

Maximum Industrial Automation & Throughput

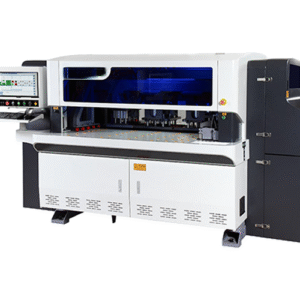

Revolutionize your mass production line with the Automatic CNC Panel Saw with Rear Feeding Lift Table Rome 3800P. Designed for large-scale furniture manufacturers, this machine eliminates the bottleneck of manual loading. By integrating a heavy-duty hydraulic lifting platform, the Rome 3800P allows for continuous, automated operation, making it the ultimate Automatic CNC Panel Saw with Rear Feeding Lift Table for factories demanding speed, safety, and efficiency.

Why Choose the Rome 3800P with Rear Feeding?

1. Automated Rear Loading System The standout feature of this model is its integrated rear hydraulic lift table. It automatically feeds stacks of panels into the machine, significantly reducing labor intensity and downtime. While the machine cuts one stack, the operator can prepare the next, ensuring near-continuous operation. This capability defines it as a premier Automatic CNC Panel Saw with Rear Feeding Lift Table.

2. Heavy-Duty Production Power Built for 24/7 operation, the Rome 3800P is powered by a robust 18.5 kW (25 HP) main motor (optional high-power configuration) or a standard 15kW motor, ensuring it can cut through high stacks of MDF, particleboard, or solid wood with ease. The massive steel frame, weighing over 7000 kg, absorbs all vibration, delivering a pristine cut quality even at maximum speeds.

3. Advanced Gripper & Positioning Technology Precision is paramount. The machine utilizes high-precision magnetic grid rulers and a servo-driven gripper system. The grippers feature a double-finger structure to securely hold heavy stacks during the rapid push-and-pull process, ensuring cutting accuracy to within 0.1mm.

4. Intelligent Optimization Software Control your production with an advanced PC interface. The integrated software not only controls the machine but also optimizes cutting patterns to minimize waste. It supports seamless data importing from major furniture design software, making this Automatic CNC Panel Saw with Rear Feeding Lift Table the brain of your smart factory.

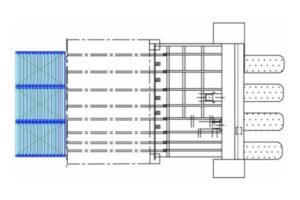

The rear feeding lifting platform adopts hydraulic control, and the lifting and lifting are stable; The magnetic grid measurement technology is used to achieve high positioning accuracy, with a minimum stacking thickness of 8mm. The stacking height is 1200mm, and the load capacity is 7000kg

Later feeding

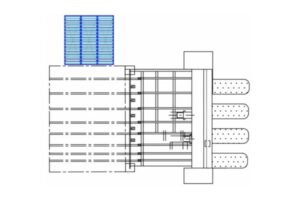

Loading on the left side

The two-finger structure heavy duty manipulator can achieve a minimum sawing board size of 50mm

Technical Specifications

| Feature | Specification |

| Model Name | Rome 3800P (Rear Feed) |

| Loading System | Automatic Rear Hydraulic Lift Table |

| Max. Cutting Length | 3800 mm |

| Max. Cutting Thickness | 90 – 100 mm (Stack Height) |

| Main Saw Motor Power | 15 kW / 18.5 kW (High Torque) |

| Scoring Saw Motor Power | 2.2 kW |

| Saw Carriage Speed | Up to 120 m/min |

| Pusher Speed | Up to 90 m/min |

| Machine Weight | Approx. 7500 kg |

| Dimensions | Approx. 8300 x 6500 x 2100 mm |

| Control System | PC with Optimization Software |

The Smart Choice for Mass Production

The Automatic CNC Panel Saw with Rear Feeding Lift Table Rome 3800P is not just a machine; it is a labor-saving solution. By automating the loading process, you reduce the physical strain on operators and increase daily output capacity by up to 40% compared to front-loading saws.

Upgrade to the Automatic CNC Panel Saw with Rear Feeding Lift Table Rome 3800P and experience the highest standard of automated woodworking technology.