Description

Unlock Precision and Efficiency with the Ultimate 6-Sided CNC Solution

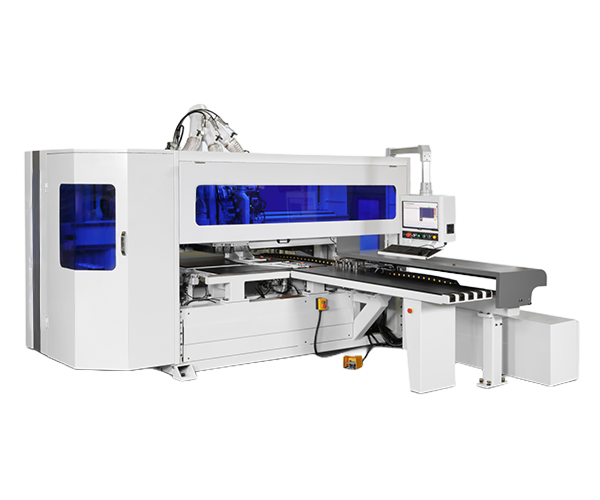

The Intelligent Woodworking Drilling and Milling Machining Center Turin stands at the forefront of modern furniture manufacturing technology. Designed for high-volume, precision-critical production, this Intelligent Woodworking Drilling and Milling Machining Center offers a comprehensive solution for six-sided drilling, grooving, and milling in a single pass. By integrating advanced CNC control with robust mechanical engineering, the Turin model eliminates the need for manual flipping, drastically reducing labor costs while maximizing throughput.

Key Features & Capabilities

-

True 6-Sided Machining: Engineered to process all six faces of a workpiece in one continuous cycle. Whether you are producing custom cabinets, wardrobes, or office furniture, the Intelligent Woodworking Drilling and Milling Machining Center ensures perfectly aligned holes and grooves every time.

-

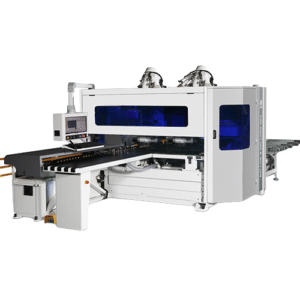

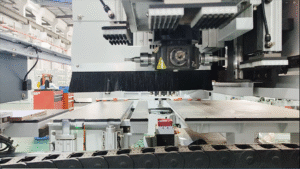

Dual Drill Bank Technology: The Turin model features a highly efficient dual-station design equipped with top and bottom drilling units. This allows for simultaneous processing, significantly outpacing traditional single-head machines.

-

Integrated Milling & Grooving: Beyond simple drilling, this machine is a full-service Intelligent Woodworking Drilling and Milling Machining Center. It is equipped with high-speed milling spindles capable of handling Lamello invisible connections, odd-shaped cutting, and complex grooving requirements.

-

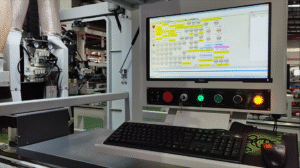

Seamless Software Integration: Powered by an intelligent CAM/CAD interface, the machine supports direct data import (XML, MPR, DXF) from major furniture design software. The barcode scanning system automates file loading, ensuring a “scan-and-go” workflow that minimizes operator error.

Technical Advantages

-

Heavy-Duty Construction: Built on a rigid, stress-relieved steel frame, the Turin ensures vibration-free operation even at high processing speeds (up to 130m/min positioning speed).

-

Precision Components: Utilizing premium servo motors and high-precision linear guides, the Intelligent Woodworking Drilling and Milling Machining Center Turin guarantees accuracy down to 0.1mm, essential for modern knockdown furniture assembly.

-

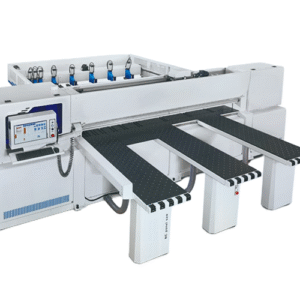

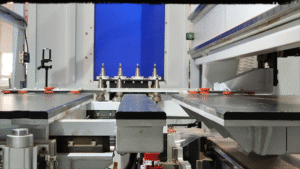

Air-Float Table: The feeding table features an air-floating design to protect delicate surface finishes from scratches during material handling.

-

Smart Clamping System: The intelligent gripper system automatically adjusts its position to avoid collisions with drill bits, allowing for uninterrupted high-speed machining.

Applications

This machine is the ideal choice for manufacturers focused on:

-

Custom Whole-House Furniture

-

Kitchen Cabinetry & Wardrobes

-

Panel Furniture Assembly

-

Office & Commercial Woodworking

Upgrade your production line today with the Intelligent Woodworking Drilling and Milling Machining Center Turin—where speed meets intelligence.

German bus system

Front and rear flat push air flotation table

C-axis360°Rotating cutter head

6meter-long guide