Description

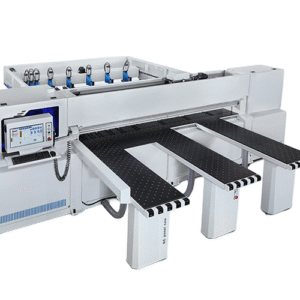

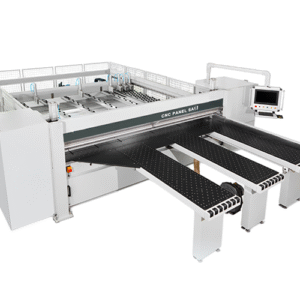

Unlock the future of high-speed furniture production with the Intelligent Woodworking Drilling and Milling Machining Center Naples. Engineered for manufacturers who refuse to compromise between speed and precision, this heavy-duty CNC solution redefines efficiency. Whether you are producing bespoke cabinetry or high-volume panel furniture, this machine serves as the backbone of a smart, automated factory line.

Why Choose the Naples Machining Center?

The Intelligent Woodworking Drilling and Milling Machining Center is designed to eliminate bottlenecks. By integrating advanced six-sided drilling technology with dual-station capabilities, the Naples model allows for simultaneous processing of multiple workpieces. Its proprietary collision interference prediction algorithm ensures that complex drilling and milling tasks are executed flawlessly, protecting your materials and maximizing uptime.

Key Features & Benefits

-

Dual-Station Productivity: Equipped with independent left and right working stations, this machine allows operators to load and unload on one side while the other processes, or to process two different boards simultaneously.

-

Comprehensive 6-Sided Processing: Complete drilling, grooving, and milling on all six faces of a panel in a single cycle. This “one-shot” processing eliminates the need for manual flipping, ensuring absolute accuracy.

-

High-Speed Biaxial Drilling: The machine features biaxial symmetric double drill chucks. This innovative design allows for the simultaneous processing of coaxial holes, effectively doubling the processing speed compared to standard single-head machines.

-

8-Position Automatic Tool Changer (ATC): The integrated 8-slot tool magazine allows for seamless transitions between different milling and slotting tasks without manual intervention, drastically reducing setup time.

-

Intelligent Safety Algorithms: Built-in software automatically calculates and predicts potential tool paths to avoid collisions, ensuring safe operation even during high-speed, complex machining.

-

Flexible Integration: The Naples unit is versatile enough to operate as a high-performance standalone unit or be integrated into a fully automated production line with robotic loading arms.

Technical Specifications

| Specification | Details |

| Model Name | Naples (SKD-6125EB/2 Base) |

| Processing Capability | 6-Sided Drilling, Milling, Grooving |

| Drill Configuration | 6 Drill Chucks, 4 Spindles |

| Working Stations | Double Station (Left & Right) |

| Max. Workpiece Width | 1200mm (Left Station) / 650mm (Right Station) |

| Min. Workpiece Size | 230mm (Length) x 35mm (Width) |

| Max. Workpiece Thickness | 60mm |

| Machine Weight | Approx. 7000 KG |

| Total Power | 59 KW |

| Dimensions | 6550mm (L) x 5900mm (W) x 2200mm (H) |

Ideal Applications

This Intelligent Woodworking Drilling and Milling Machining Center is the perfect solution for:

-

Custom Furniture Manufacturing: Kitchen cabinets, wardrobes, and office furniture.

-

Panel Processing: High-volume cutting and drilling of MDF, particleboard, and plywood.

-

Smart Factories: Facilities looking to transition to Industry 4.0 standards with automated data handling and seamless production flow.

Six-meter long extended rails

Vacuum Hood

Imported devices