Description

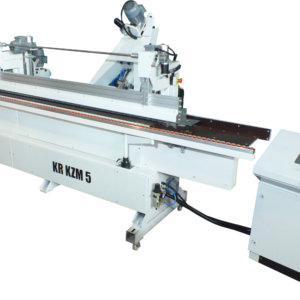

The Profile Sanding Machine KR PM 10 is a new generation full automatic machine which is developed for sanding door cases, trims, baseboards and all types of corded profiles raw or primed. All Profile Sanding Machine KR PM 10 units are PLC controlled and movable, allowing the wood sanding machine to sand flawlessly. Profile sanding was always a challenge for the wood production. This feature prevents problems such as rounding of the corners of the head & end of the profiles and removing the paint on these sections. Factory warranty can be extended to two year, please ask Moon Machinery for details.

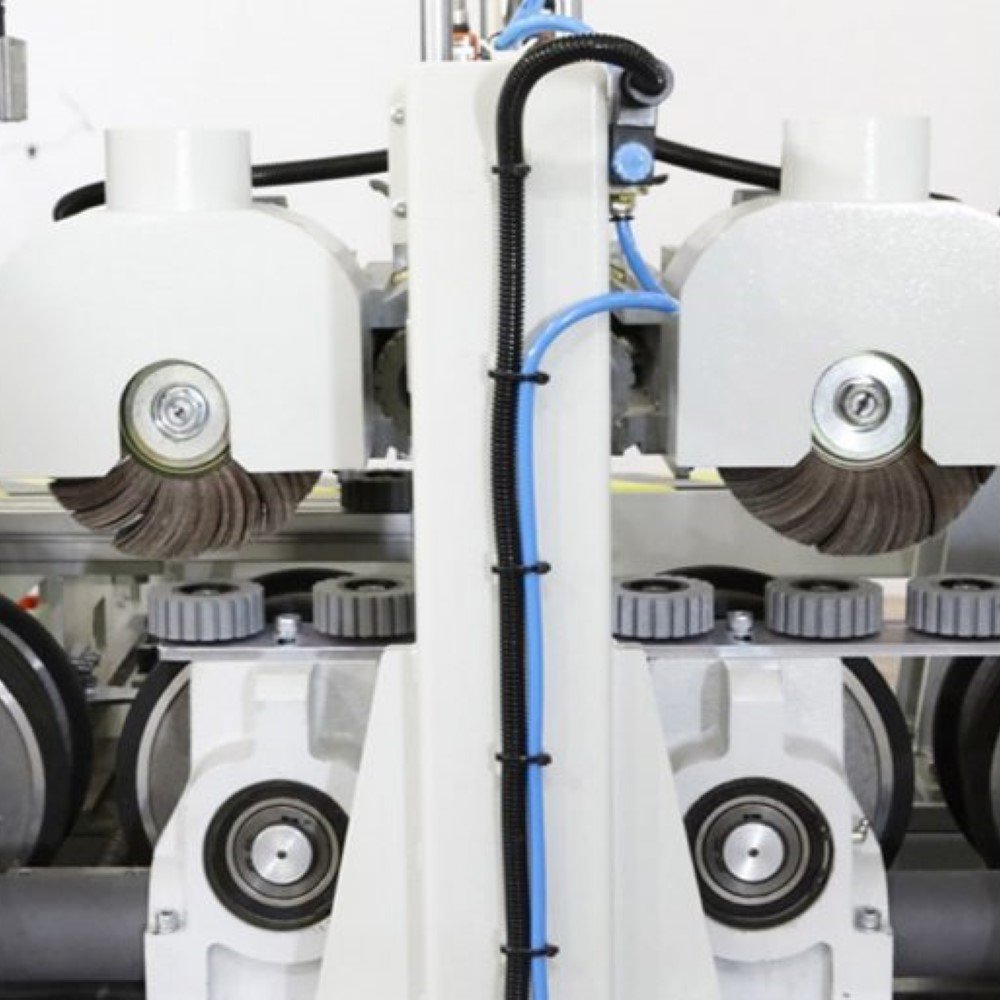

There are 2 oscillatory orbital sanders for profile edges and 1 oscillatory orbital sander for the top surface of the profile as a standard on the Profile Sanding Machine KR PM 10. These motors, whose are pressing forces, start&finish points can be adjusted, are PLC controlled and only press when they see the product. The cylindrical brush sanding unit with oscillation is standard on the Profile Sanding Machine KR PM 10. This unit is PLC controlled and its height, speed and distance settings can be made easily.

Usage Areas

Door frames, door trims, baseboards, all kinds of wooden profiles sand to perfection.

Click here to see all sanders.

canada, toronto, moon machinery, kama, karabudak machine, edge sanding machine, edge sander, spray coating machine, spray coater, oscillating system edge sander, drying systems, dry booths, furniture spraying, coating, profile sanding machine</p