When you’re running a mill in your woodworking shop, you must have all the tools you need to get the job done. And one of the most important pieces of equipment is a multihead horizontal resaw machine. It’s like having multiple bandsaws in one, and it significantly speeds up production time. If you’re trying to get through as much wood as possible, an ordinary bandsaw just won’t cut it. The time and money that you invest in your equipment is essential for your business to succeed, so it makes sense to purchase high-quality machines that are built to last. Check out our inventory to find our multi horizontal resaw machine. We offer installation and after purchase maintenance services with one-year warranty. Moreover, since it’s an inventory item, we can bring it and install it quickly, which would save you time. If you’re interested in saving time and money in your woodworking business, contact us now!

Why Are Multihead Resaw Machines So Important?

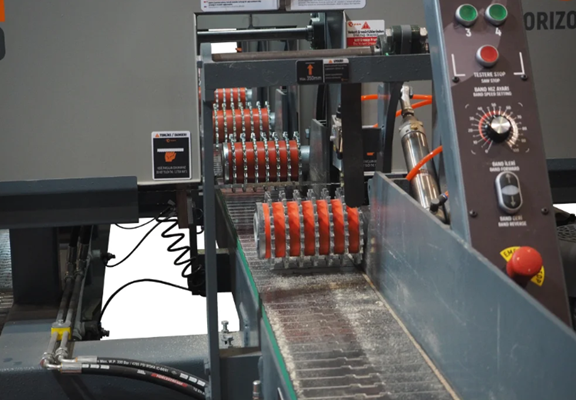

A multihead resaw machine is a large, heavy-duty machine that is designed to power through a lot of work. It consists of multiple saw heads mounted on rails, and the heads can move back and forth to make numerous cuts at once. It’s like having a band saw, a table saw, and a jointer all in one.

The machine is designed to speed up the production process, which saves you time and money. For example, if you need to make a large number of 1×4 boards in one day, having a table saw would be extremely time-consuming. But with a multihead resaw machine, you can rip huge pieces of lumber in half and make two 1×4 boards at once.

5 Benefits of Having a Multihead Resaw Machine in Your Woodworking Shop

– It Allows You to Cut Multiple Pieces at Once

Multihead resaw machines can cut through large pieces of lumber, so you can make multiple boards at once. You can even rip a large board in half, and then cut each half into smaller boards. This is a great way to make large amounts of small parts, like wooden dowels. – It Lets You Change Blades Without Stopping the Machine

When one blade becomes dull, you can quickly switch it out for a new one without stopping the machine.

– It Speeds Up Production Time for Certain Jobs

If you need to make a large number of the same type of boards, a multihead resaw machine can speed up the process.

– It Allows You to Make Consistent Cuts Across Multiple Pieces

With a single blade, you can make consistent cuts on one piece of lumber, but you can’t make similar cuts on multiple pieces. But with a multihead resaw machine, you can make identical cuts across multiple boards. It’s easy to set up the machine to make consistent cuts, and you can make sure each board has the same thickness, width, and length.

– It Reduces Warping and Improves the Quality of Your Boards

Because a multihead resaw machine uses more blades to cut through a board, it’s less likely to warp the lumber. When a single blade cuts through a board, it leaves a lot of stress in the wood, which can cause the board to warp. But a resaw machine can reduce this warping, which improves the quality of your final product.

3 Advantages of Resawing Your Lumber Before You Insulate It

– You Get More Pieces Out of Each Board

When you rip lumber before you insulate it, you get more pieces out of each board. For example, you may be able to get four pieces from a single 4×8 board. That means you’ll be able to complete more projects with what you have on hand.

– You Can Save Money on Insulation Materials

Depending on where you live, insulation can be a significant investment. But if you rip your lumber before you insulate it, it’s easier to make sure you have the correct thickness.

– You Save Time When Cutting Your Boards

There’s nothing more frustrating than trying to cut boards to a certain length and then trying to find the perfect width. When you rip your lumber before you insulate it, you can make sure each board is the right length and width.

Conclusion

A multihead resaw machine is an essential piece of equipment in any woodworker’s shop. It’s like having multiple bandsaws in one, and it speeds up production time while improving the quality of your final product. When you are searching for a machine like this, it’s important to find a reputable manufacturer that makes durable, long-lasting products. You don’t want to purchase something cheap that won’t last, and you don’t want to get stuck paying for expensive maintenance repairs either. Keep in mind that a multihead resaw machine is an expensive piece of equipment, so you may have to save up for it. Or you can look into financing so that you can pay off the machine over time. Whatever you do, don’t try to skimp on this purchase. A high-quality machine will make your life easier, and it will last for years.