Description

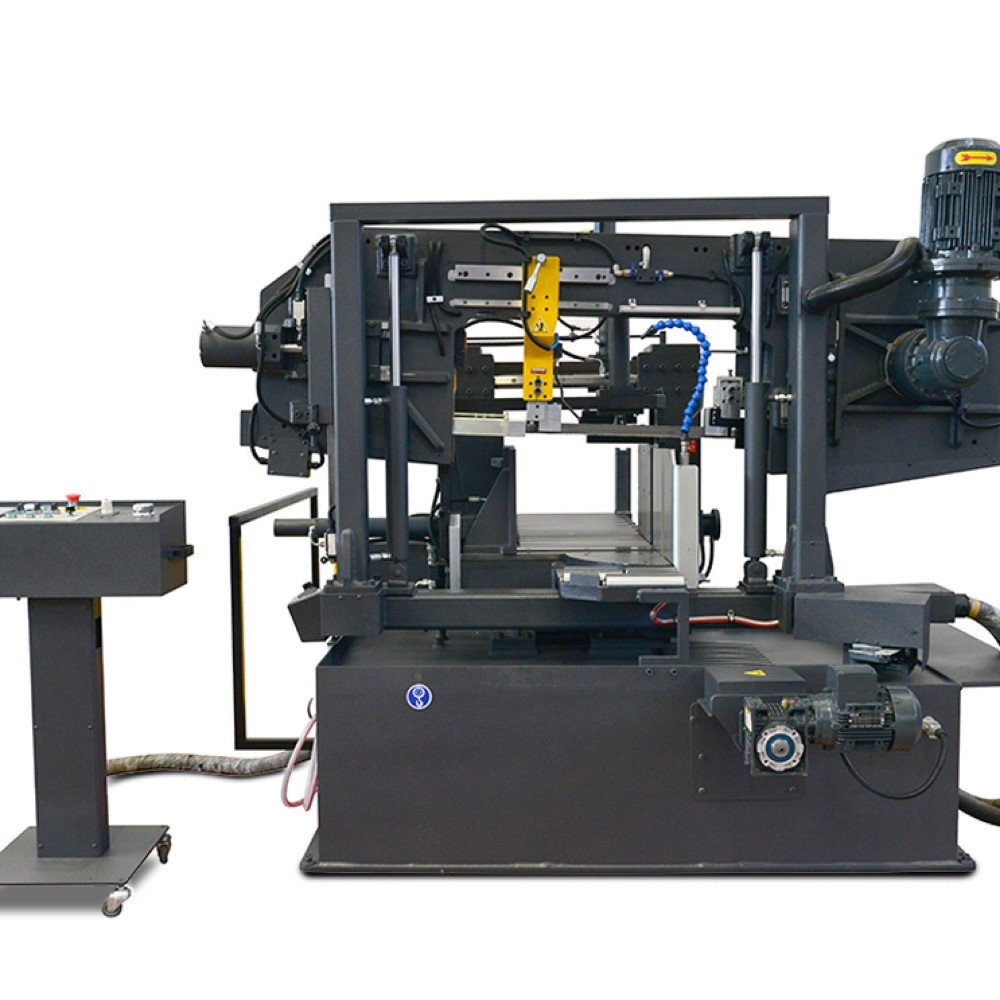

The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-325CGS NC is a precision-engineered, PLC-controlled horizontal band saw designed for efficient one-side mitre cutting of various materials. This servo-feeding machine utilizes linear guide ways to deliver consistent, high-accuracy results, even in high-volume or multi-cut applications.

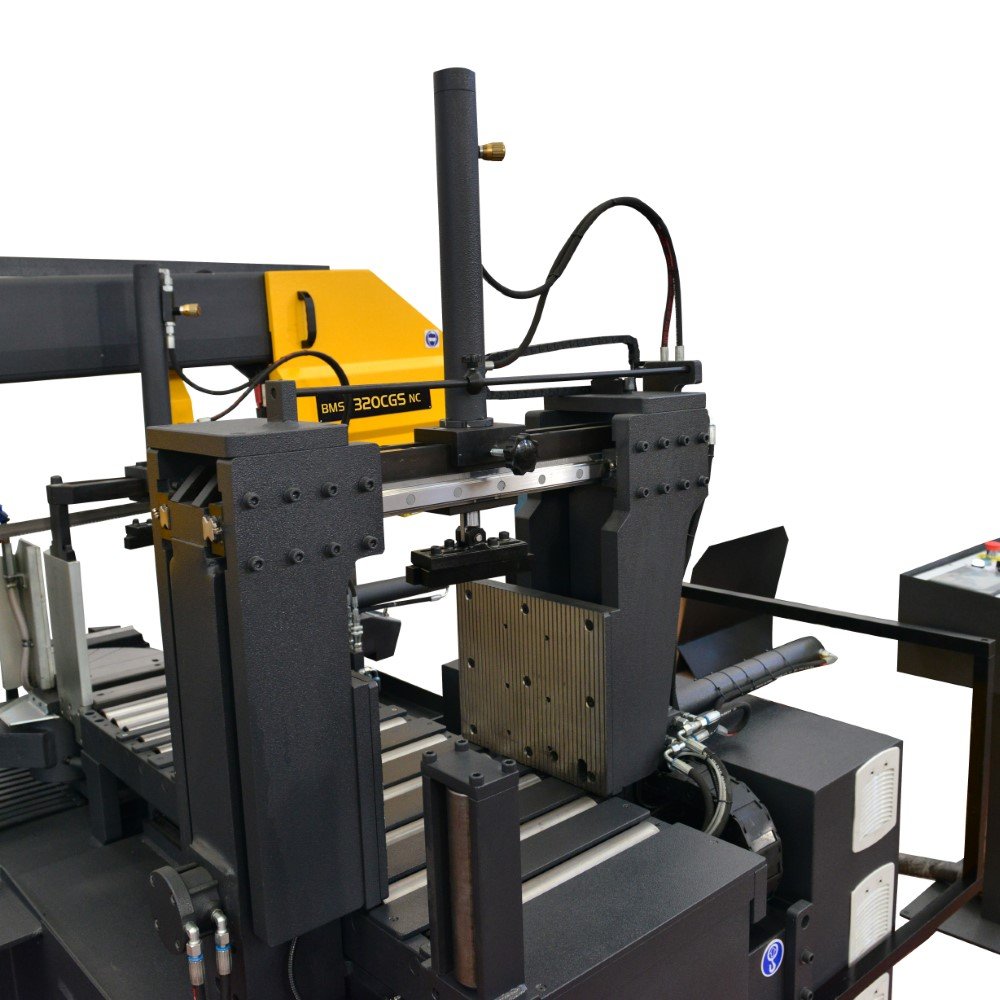

With a cutting angle range from 30 to 90 degrees, the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-325CGS NC supports up to 10 programmable sequences for length and quantity, easily monitored via its digital display. The stroke-based measurement system uses a 19 11/16″ (500mm) repeatable stroke for optimized material handling. At 90 degrees, its cutting capacity reaches up to 12 9/16″ (320mm) x 17 11/16″ (450mm) for flat materials, and 12 3/4″ (320mm) in diameter for round stock.

Advanced features include automatic height adjustment sensors that allow the bow to quickly approach the material, cutting down cycle time without sacrificing precision. After each cut, the bow retracts hydraulically, ready for the next operation. A mechanical switch oversees the entire cutting cycle, ensuring safe and reliable operation. Bow angle adjustments are controlled by a hydraulic brake system and a secondary digital angle counter located on the machine’s main body.

Like all Bekamak equipment, the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-325CGS NC prioritizes operator safety, with all mechanical and electrical systems built to meet the highest standards. The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-325CGS NC is the ideal solution for precision mitre cutting in demanding metalworking environments.

Click here to see all twin pillar saws.