Description

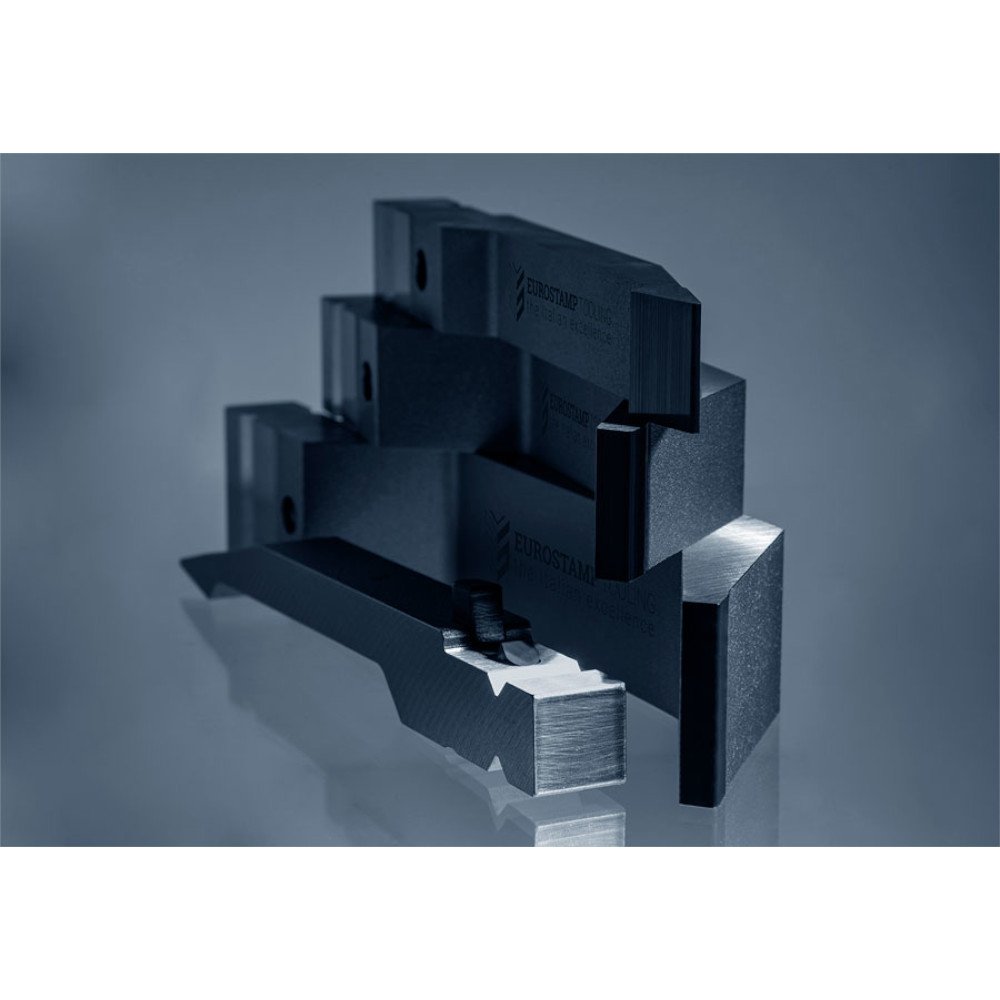

Wila style tooling, wila style tooling, eurostamp trumpf tooling eurostamp amada promecam bystronic ehs style press brake tooling

Punches (top tools) (BIU)

- Compatible with all WILA New Standard Premium and New Standard Pro and American Style Clamping Systems.

Dies (bottom tools) (OZU)

- For all press brakes and dies with a .531″ x .866″ (WxD) (13.5 x 22 mm) tang slot.

The advantages

- Fast and easy to configure tool lengths

- Extremely accurate, fast, safe and flexible

- Very high quality finish

- Suitable for all press brakes and all bending applications

- Maximum performance when used in combination with New Standard Tool Holders

Special coating: OZU-ZN

There is high risk of sheet damage and accelerated die wear when electrolytic or hot galvanised sheet materials are processed on a regular basis. The other disadvantage is that tools must be cleaned continuously. WILA has developed a special coating to reduce this known a: OZU-ZN. This coating forms a protective layer which is applied to WILA’s CNC deep-hardened dies. This drastically reducees die wear and prevents zinc deposits from forming on bending radii and makes cleaning a thing of the past. Read more about OZU-ZN>>

Extra large shoulder radii

New Standard Premium dies with a working height of 3.937″ (100 mm) and New Standard Pro Dies, feature extra large shoulder radii. This helps to reduce marking on the material. Additionally, any protective coatings used will remain intact for far longer.

Premium Tooling

Bending technology of the highest standards

- For extreme precision and bending performance

- Very high workload capacity and maximum durability

- All load bearing and wear surfaces are fully CNC-Deephardened® (ca. 58 HRC) for maximum durability

- Very high quality finish

- Provides maximum long-term performance

Pro Tooling

A high quality alternative for press brakes with limited open height

- Very high quality in accordance with WILA standards

- Functionally comparable with WILA New Standard Premium Tooling, with reduced depth of hardening on load bearing and clamping surfaces (52-56 HRC).

- Provides high level of durability in most bending applications

- Great value for the investment

Tool Extenders

New Standard Tool Extenders help to create a suitable connection between the press brake’s clamping system and the tooling that forms the sheet material. Some examples are Adapters, Extenders, Radius Tool Holders, Radius Tooling Inserts and flattening tools.

Heavy Duty

WILA’s New Standard ‘HD’ Heavy Duty Tooling System is a new addition to the New Standard family of products. All items in this product line are designed to make it possible for fabricators that fabricate heavy plate materials to maximize the productivity of their press brakes while increasing operator safety.

Click here to see all tooling items.