Description

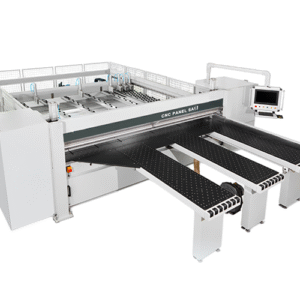

Revolutionize your furniture production line with the Intelligent Woodworking Drilling and Milling Machining Center Genova. Designed for high-volume, custom furniture manufacturing, the Genova is more than just a drill; it is a comprehensive solution for six-sided processing that combines speed, precision, and intelligent software integration.

As a cutting-edge Intelligent Woodworking Drilling and Milling Machining Center, the Genova eliminates the need for manual flipping of panels. It automatically processes all six faces of a workpiece in a single pass, significantly reducing labor costs while maximizing throughput.

Why Choose the Genova Machining Center?

In the competitive landscape of panel furniture manufacturing, efficiency is currency. The Genova is engineered to bridge the gap between complex design requirements and mass production speed.

-

True Six-Sided Processing: The machine comes equipped with dual drill banks (top and bottom) and heavy-duty spindles. This allows the Intelligent Woodworking Drilling and Milling Machining Center to complete vertical drilling, horizontal drilling, and groaming/milling on all sides simultaneously.

-

High-Speed Throughput: With advanced servo control and optimized path planning, the Genova minimizes non-cutting time. It handles continuous feeding for batch production, making it ideal for cabinets, wardrobes, and office furniture.

-

Seamless Software Integration: The “Intelligent” aspect of the Genova lies in its compatibility. It easily integrates with major furniture design software, reading XML/MPR files directly to execute drilling and milling commands without manual programming.

Key Technical Features

-

Dual Spindle Configuration: Capable of intricate milling tasks such as Lamello cuts or specialized hardware recesses.

-

Air Table Surface: Prevents scratching of delicate surfaces like high-gloss acrylic or melamine during movement.

-

Automatic Gripper System: Ensures precise positioning of the panel during the high-speed drilling cycle.

-

User-Friendly Interface: A graphical HMI allows operators to monitor the status of the Intelligent Woodworking Drilling and Milling Machining Center in real-time.

Applications

The Genova is specifically built for the “Nest-and-Drill” cell concept. Once panels are cut on a CNC router or beam saw, the Genova takes over to finish the job.

-

Custom Cabinetry: Kitchen and bath cabinets requiring precise hinge and shelf holes.

-

Knock-Down Furniture: Perfect for Minifix and Rastex cam-lock connector preparation.

-

Office Furniture: Handles complex wire management grommets and structural joinery.

Upgrade your factory with the Intelligent Woodworking Drilling and Milling Machining Center Genova and experience the future of automated woodworking.