Description

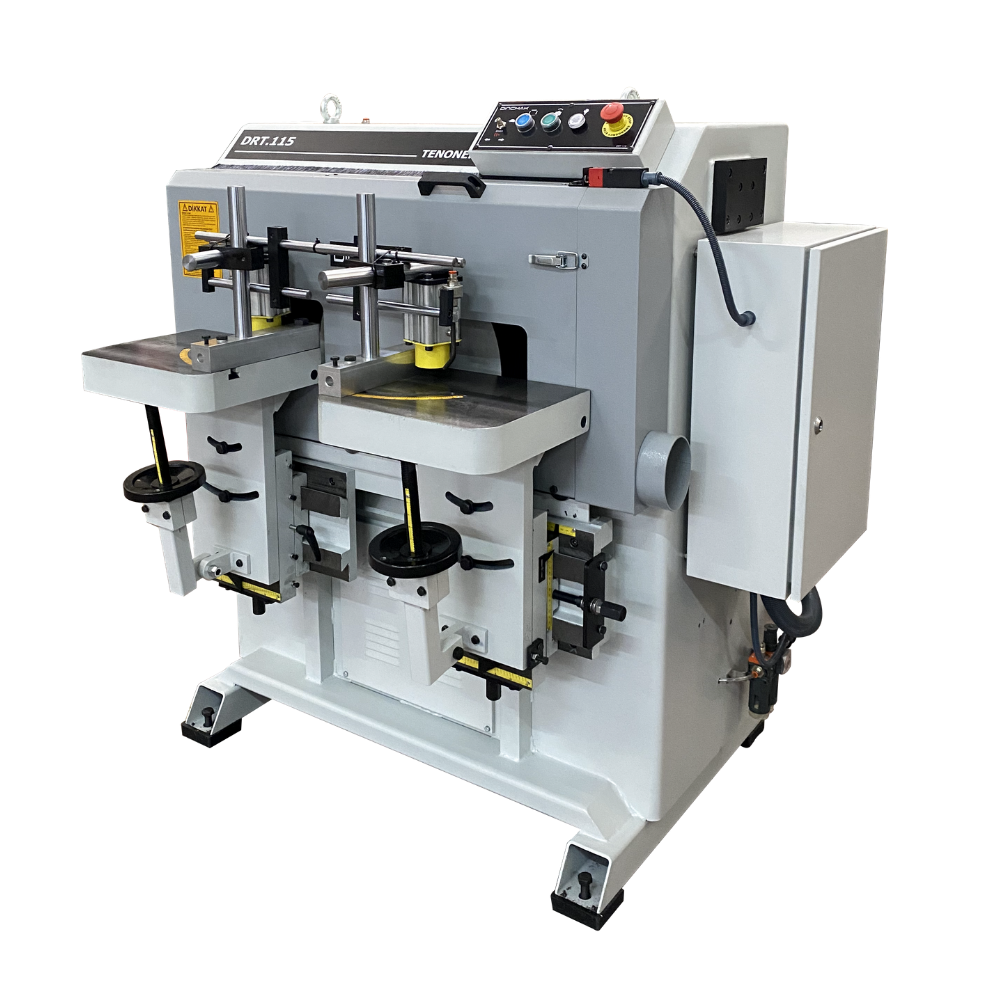

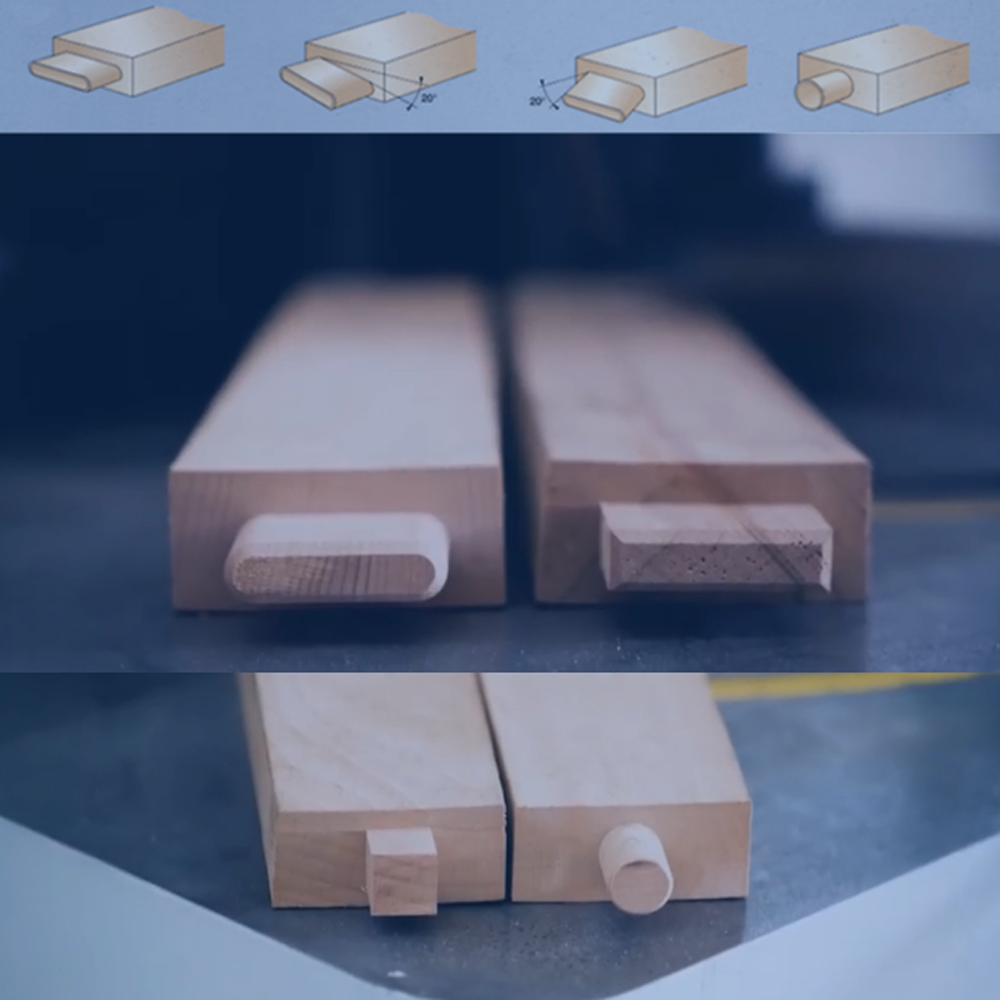

The Rectangular Round End Tenoner is a highly versatile and efficient woodworking machine designed to streamline the tenoning process for both rectangular and round-ended workpieces. One of the key features of the Rectangular Round End Tenoner is its dual work-table design. While one work table is actively processing a part, the operator can prepare the next piece on the second table. This smart configuration eliminates idle time and significantly boosts overall production efficiency.

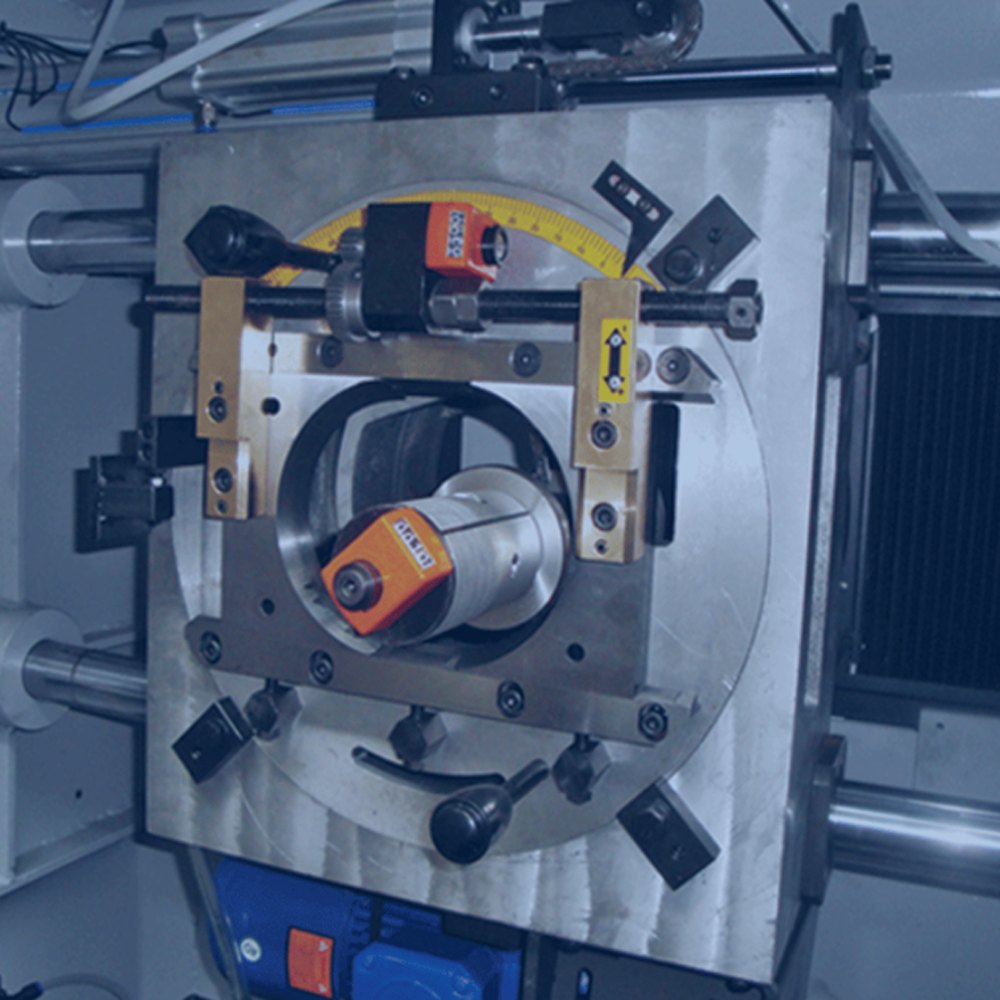

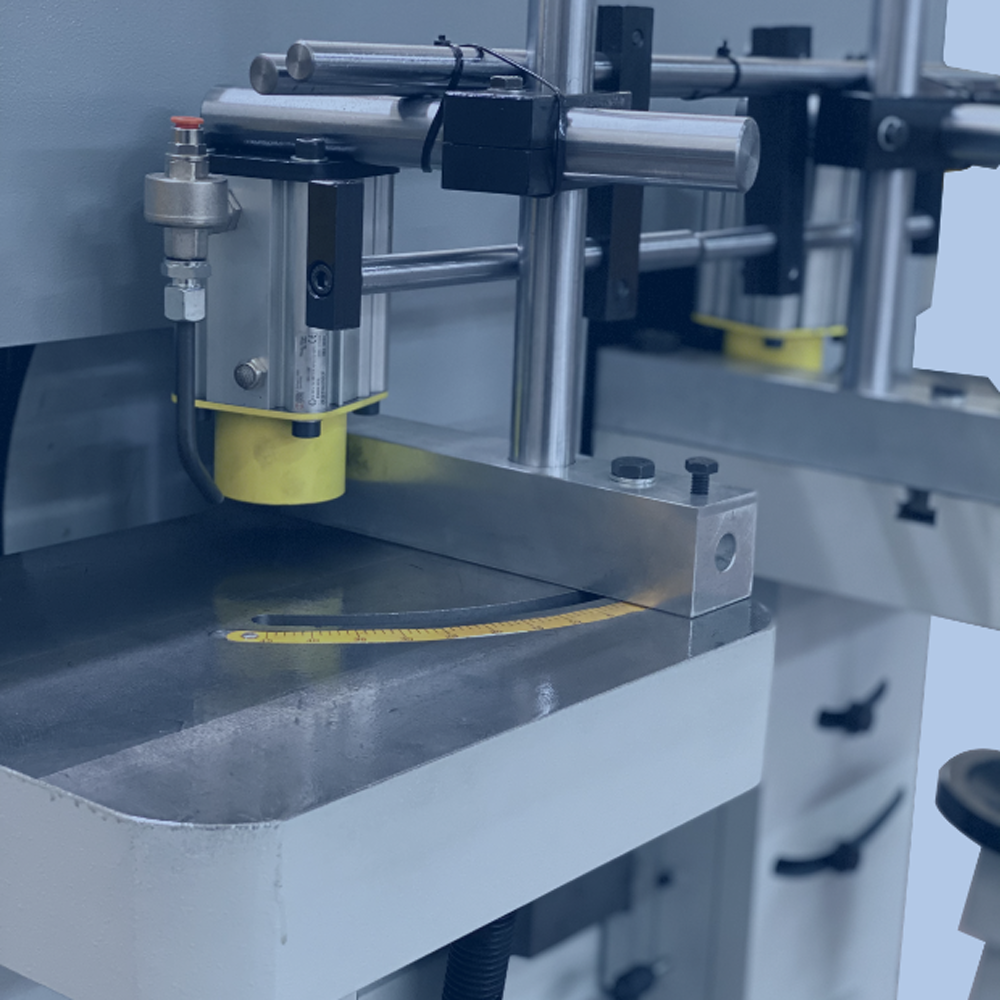

The cutting heads on the Rectangular Round End Tenoner move smoothly from one work-stand to the other, performing operations with speed and precision. The machine allows full control over processing speed, enabling the operator to balance speed and surface quality based on the material type and job requirements. Tenon width and thickness adjustments are both guided by easy-to-read mechanical indicators, ensuring repeatable and accurate settings with minimal setup time.

Each of the two work-tables is independently adjustable in both height and angle, offering great flexibility for working on complex or customized tenon profiles. Whether the job requires vertical, horizontal, angled, or straight tenon shaping, the Rectangular Round End Tenoner delivers reliable and consistent results. This machine is ideal for modern workshops demanding speed, accuracy, and adaptability.

Click here to see all furniture working machines.