Description

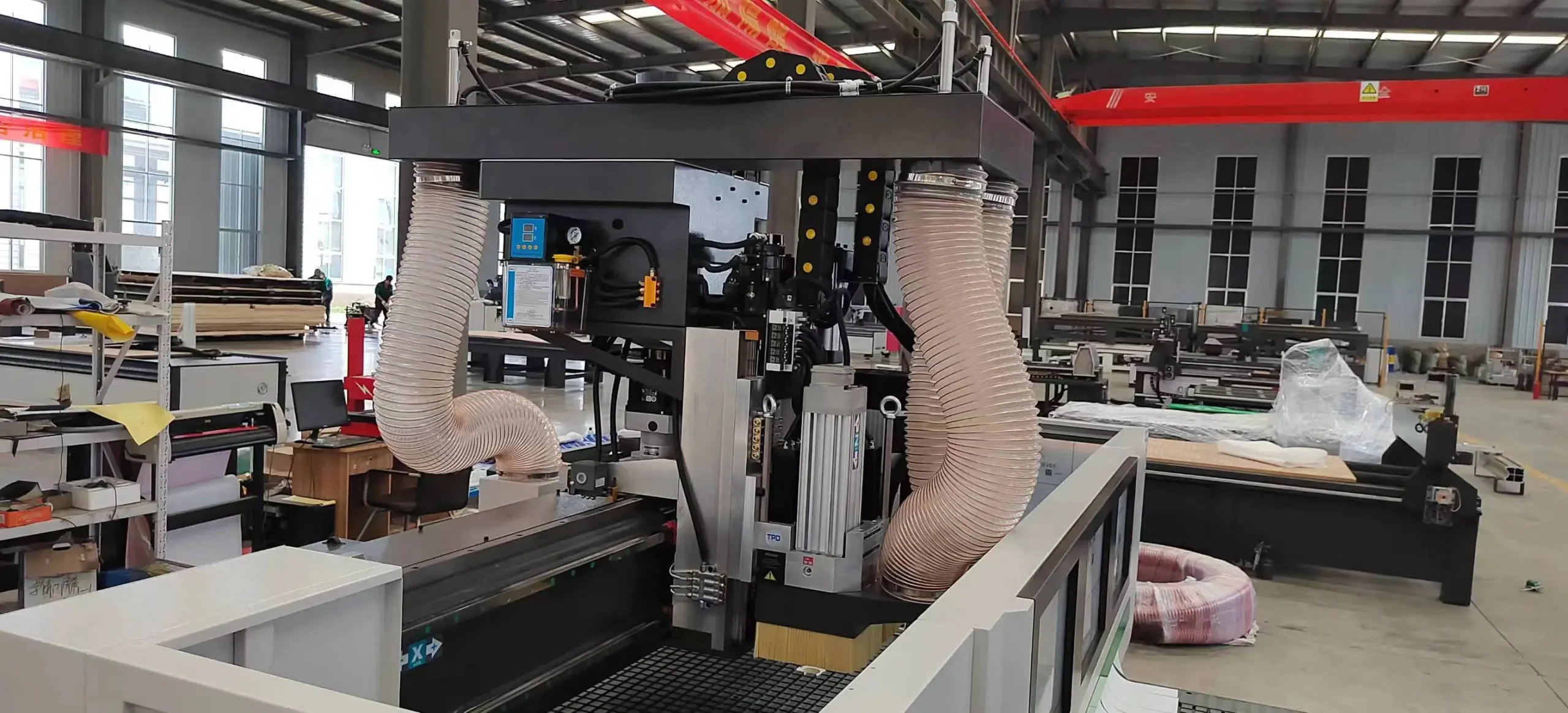

The Customized Nested Based CNC Router Wakizashi is designed for high-speed full format cutting and trimming operations with (plywood, furniture board, chipboard, MDF), various composite materials and plastics, as well as soft and hard wood. It is effectively used in small-scale and large-scale production.

The CNC Router KN-3710D is equipped with an Italian TPA controller with Tpa WSCM, Tpa Cad, Tpa Nesting. The CNC Router KN-3710D has a wide range of application functions. The intuitive interface of the CNC Router KN-3710D allows you to quickly prepare the staff of the enterprise for programming and work on the machine.

Customized Nested Based CNC Router Wakizashi Key Features:

- Processing area 3100*2150 mm;

- Spindle: HSD (Italy) – 13.2 kW with HSK-63F cartridge;

- Drilling group for 10 vertical spindles with a power of 1.7 kW, 6000 rpm and a bore diameter of 10 mm;

- Servo motors for moving the gantry and spindle along the X/Y/Z axes: – 1.5 kW;

- Travel speed along the X/Y/Z axes: – 80/80/30 m/min;

- The mechanism of automatic tool change of revolving type for 12 tools;

- TPA control desk in Russian (Italy) – includes: Tra WSCM – machine control;

- Tpa Cad – modeling; editing, creation of control programs;

- KDT Remote Services – (tele service) remote service via Internet connection for the purpose of troubleshooting, diagnosis, maintenance, repair or process optimization;

- Vacuum pumps Becker with a power of 5.5 kW – 2 pcs.;

- 6 vacuum zones;

- Vacuum suckers for autoamtic load of panels;

- Sheet alignment mechanism;

- Tool calibration sensor;

- Double-circuit lubrication system;

- Airflow of the milling zone;

- Portal type construction;

- Pneumatic stops – 6 pcs.;

- Automatic loading with label printer;

- Automatic table with belt conveyor for unloading parts.

CNC Router KN-3710D Technical Specifications:

-

Control system TPA (Italy) Table size, mm 3100×2150 Distance from spindle nose to table surface, mm 72-252 Spindle HSD, 13.2 kW, 24000 rpm, clamp HSK-63 F drilling head 10 vertical spindles, 1.7 kW, 6000 rpm Tool change revolving for 12 places Maximum tool diameter, mm 140 Maximum tool length (excluding workpiece height), mm 100 Travel speed in X/Y/Z, m/min 80/80/30 Servo power in X/Y/Z, kW 2*1.5/1.5/1.5 Number of vacuum zones, pcs 6 Total power consumption, kW 32.8 Productivity of vacuum pumps, m3/hour 2×250 Overall dimensions LxWxH, mm 4500x3350x2415 Weight, kg 5000 Working area of the loading table, mm 3050x2100x500 Loading table power, kW 2.2 Working area of the receiving conveyor, mm 3210×2120 Receiving conveyor power, kW 1.5

Elevate your craftsmanship with the Customized Nested Based CNC Router Wakizashi – where Italian ingenuity meets unwavering performance.