Description

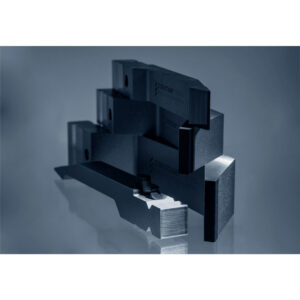

esh style tooling, esh style tooling trumpf tooling eurostamp amada promecam bystronic ehs style press brake tooling

General characteristics of ESH style tooling.

All tools in this series are manufactured using premium CrMo steel, which thanks to its high ultimate tensile strength (UTS) (950- 1050 N/mm²) allows for higher tonnages with the same tooling cross-section. The hardening treatments are different for punches and dies: this is to achieve the best performance according to how the tools are used.

Innovation in upper tools.

- Punch tips are induction hardened to 55-56 HRC, for an average depth greater than 3mm: higher hardness of the tip radius and of the whole area touching the sheet metal

- The range includes punches with 86°; 60°; 30° and 26° angles

- Punch shapes are newly designed so as to reach maximum flexibility, and to increase the number of possible profiles

- Working height is 120 mm, 4 11/16″ inch and adjustable to the daylight and stroke parameters of most press brakes on the market

- Working height is the same for all the punches in this range: it is possible to fabricate complex profiles with 90° angles installing any punch with “staged” bending.

Innovation in lower tools (die inserts).

- Die inserts undergo nitriding processes: the whole die surface, and not only die shoulders, is covered with a nitride layer with a hardness of up to 65 HRC. This allows to significantly reduce the risk of damaging the internal surface of the die width and to prevent particles of zinc and other debris from adhering to the die shoulders and internal surface of the V opening. Finally, the die surface is phosphate coated in order to increase corrosion resistance

- The range includes die inserts with 86° and 30° angles with widths from 6 to 25 mm, 1/4″ to 15/16″ inch

- The die insert shapes have been newly designed in order to meet modern requirements

- The fillet radii are large, to reduce any possible marks on the sheet metal

- The body of small-V dies has been “relieved” (made thinner) to provide higher versatility when forming complex bends, such as, for example, offset bends, which are really frequent when working thin sheet metal

- External edges of the die inserts are chamfered, to reduce chances of collision with any obstacles close to the bending lines.

Upper Tools (Total length 800 mm, 31 1/2″ inch)

100 mm, 3 15/16″ inch SX – 10 mm, 3/8″ inch – 15 mm, 9/16″ inch – 15 mm, 9/16″ inch – 20 mm, 3/4″ inch – 40 mm, 1 9/16″ inch – 50 mm, 1 15/16″ inch – 150 mm, 5 7/8″ inch – 300 mm, 11 13/16″ inch – 100 mm, 3 15/16″ inch DX

Lower tools (Total length 800 mm, 31 1/2″ inch)

100 mm, 3 15/16″ inch – 10 mm, 3/8″ inch – 15 mm, 9/16″ inch – 15 mm, 9/16″ inch – 20 mm, 3/4″ inch – 40 mm, 1 9/16″ inch – 50 mm, 1 15/16″ inch – 150 mm, 5 7/8″ inch – 400 mm, 15 3/4″ inch

Click here to see all tooling items.