Description

2800SP Automatic CNC Panel Saw is a fully automatic cutting equipment that can provide a complete panel cutting solution for custom furniture manufacturing. It adopts 19″ LED display and PC computer control system, which can be connected with various brands of production data software and directly input production data. It greatly improves production efficiency and reduces the daily production cost of the factory

Side Mechanism:The side-by-side push stop CNC positioning allows for more accurate lateral pressing of the workpiece. The lateral pressure is adjustable to adapt to different thicknesses, weights, and materials of workpieces, ensuring the dimensional accuracy of sawing。

PC computer control system:Equipped with a 19″ LED screen, easy-to-use Windows operation interface, complete function keys and diagrams. Production managers can write processing programs and implement remote input in the office

Saw seat sliding mechanism:The precision chrome steel guide wheel and precision cylindrical chrome steel guide rail are adopted, and the saw seat has high linear motion accuracy and little vibration to ensure the sawing accuracy of the workpiece

Splint push device:The cleat pushing device is driven by a servo motor, and the feeding positioning is accurate through the combination of precision gears and racks to ensure the dimensional accuracy of the workpiece

New splinting device:Heavy-duty design, with sufficient grip and force to push the workpiece, ensure smooth workpiece pushing. Optimized design, new cleattic device for a minimum sawing sheet size of 45mm. The worktable is made of chrome-plated steel plate, which has high hardness and good wear resistance, reducing the friction between the plate and the worktop, and avoiding damage to the surface of the workpiece

Air cushion floating front table:Equipped with a 4KW air pump, the air cushion table uses stainless steel beads to effectively reduce the friction between the workpiece and the steel ball; The front end of the worktable is equipped with rollers, which is convenient for the workpiece to be loaded and lowered and to reduce the friction between the workpiece and the front end of the table. The lower side of the worktable is equipped with an emergency stop button for emergency protection

| Technical parameters | XPC-2800SP |

| Maximum size for processing | 2700*2700*90mm |

| Main saw power | 15KW |

| Slot saw power | 1.5KW |

| Feeding motor power | 2KW |

| The saw truck drives the motor | 2KW |

| Maximum sawing height | 90mm (optional 120mm.)) |

| Saw speed | Max.85m/min |

| saw seat return speed | 100m/min |

| Feeding speed | Max.85m/min |

| Main saw speed | 4300rpm |

| Groove saw rotation | 5900rpm |

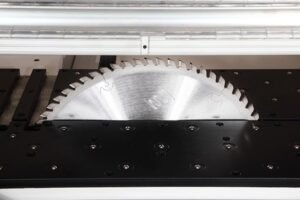

| Main saw size | φ400 (Optionalφ450) |

| Slot saw size | φ200mm |

| Operating voltage | 380V, 50HZ |

| Working air pressure | 6-8kg/cm2 |

| Total power | 27.3KW |

| Body weight | 4580KG |

| Vacuum port diameter | φ200×2, φ100×2 |