Description

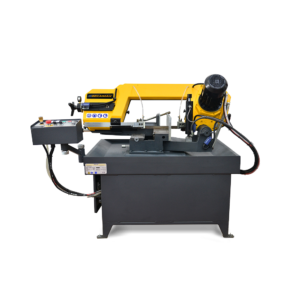

The JMJ-04 Double Head Saw is a high-performance cutting solution specifically designed for processing aluminum connectors with superior precision and reliability. Controlled by a ball screw and CNC system, it delivers efficient and consistent results that make it an ideal choice for large-volume production environments. Its automatic feeding system allows the cutting of over-length profiles, while the built-in recording system conveniently tracks the number of pieces already processed, improving production management and workflow efficiency.

Equipped with an imported carbide saw blade, the JMJ-04 Double Head Saw ensures accurate cutting, reliable performance, and exceptional durability.Both the clamping and feeding processes are managed by a ball screw mechanism, which enhances automation, reduces operator workload, and maintains stable cutting performance across a wide range of jobs. This combination of advanced technology and practical features makes the machine a powerful addition to any aluminum processing operation.

In terms of specifications, the JMJ-04 Double Head Saw operates with a 380V 50Hz power supply and a 3.0kW motor that runs at 3850 r/min. The air pressure requirement is 0.5-0.8 MPa, while the saw blade specification is Ф500mm×Ф30mm×4.4mm Z=100. It offers a generous cutting range of 135×300 mm at a 90 degree angle, providing versatility for various connector profiles. The overall machine dimension is 1700×1400×1500mm with a bracket size of 3000mm, making it compact yet capable of handling demanding workloads.

With its blend of automation, efficiency, and advanced engineering, the JMJ-04 Double Head Saw stands out as a dependable and productive tool for aluminum connector cutting applications.