Description

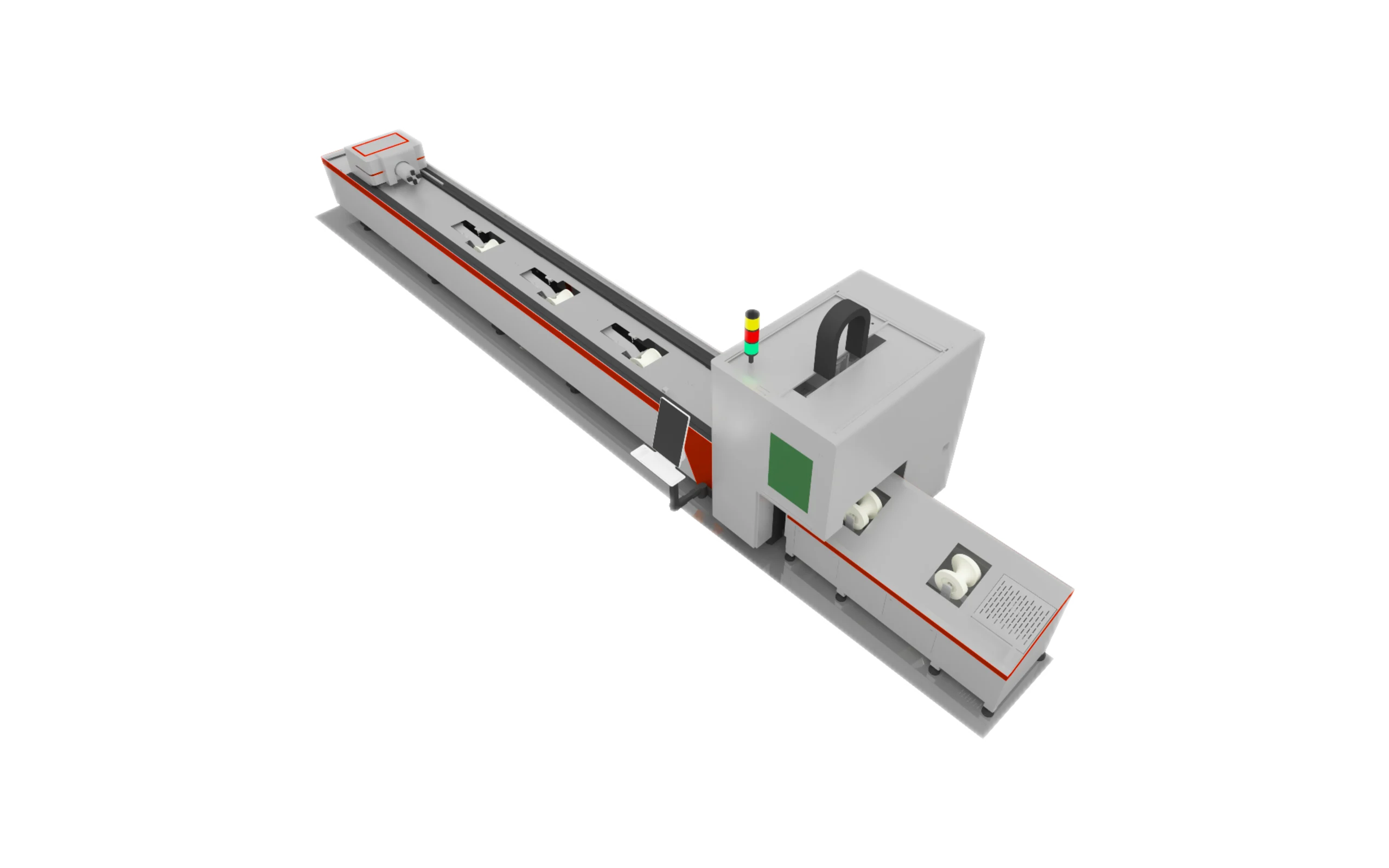

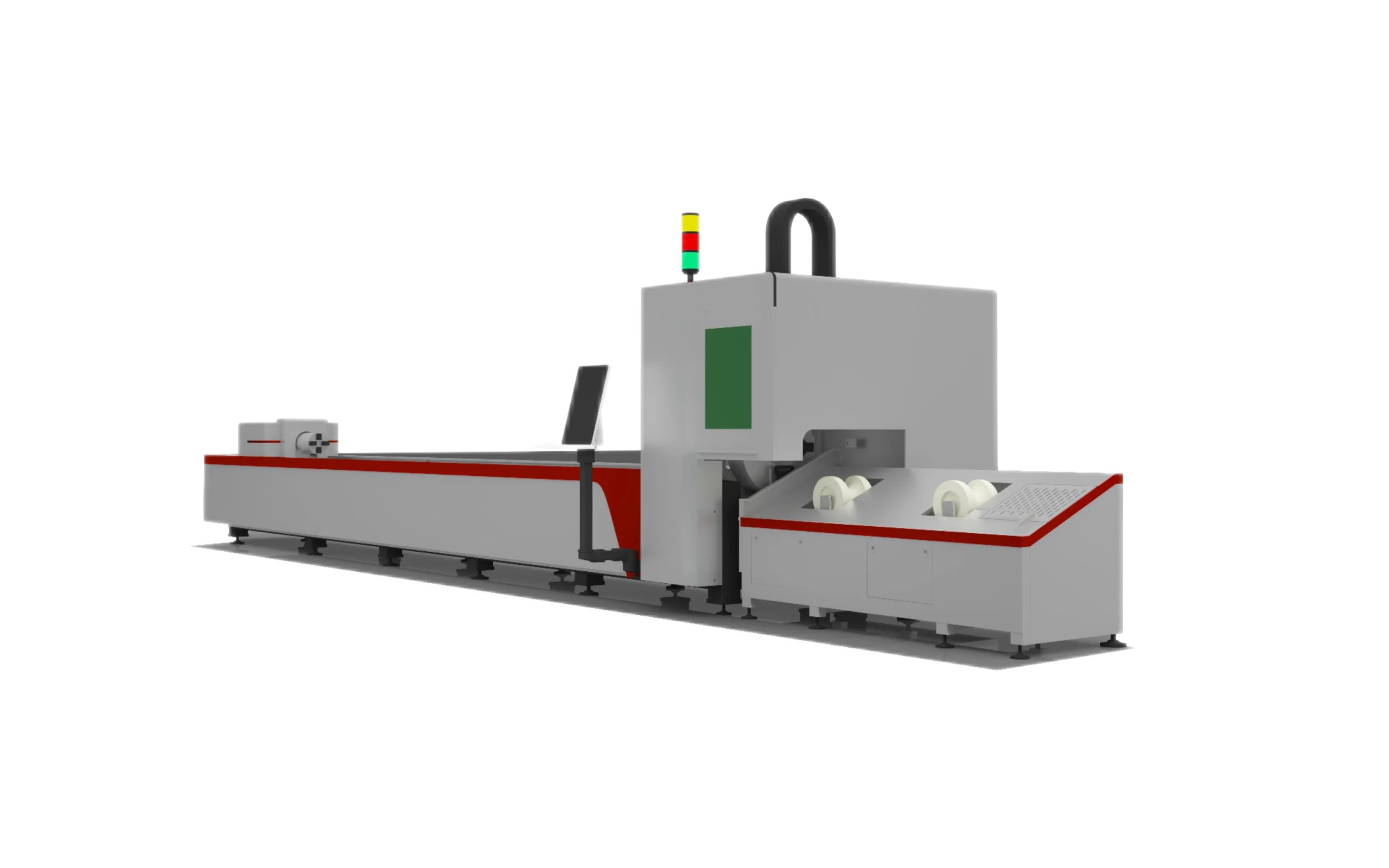

Light Duty Tube Laser Cutting Machine

Which does the Light Duty Tube Laser Cutting Machine work best ?

Large size beams have always posed a significant challenge for metal building contractors and builders, particularly in terms of transportation, handling, and accurate installation. Due to their weight and length, these beams require specialized machinery and coordinated efforts to move and position them safely and efficiently on-site. The complexity increases when working on projects with tight timelines or limited access, where any delay or error can significantly impact the construction schedule. Additionally, ensuring the structural integrity and alignment of these beams during installation demands a high level of expertise. As architectural designs become more ambitious and demand larger spans, the construction industry is turning to advanced fabrication, cutting, and lifting technologies to streamline the process and reduce the margin for error.

Material sizes:

18′ , 20 and 24′ are the most common tube sizes,.

Material wall thickness :

most material thickness reaches of 3/8″ on light duty tubes and angle profiles.

The Light Duty Tube Laser Cutting Machine is made to last with screw drive system feed and servo system, tube laser cutting machines equipped with automatic lubrication system to ensure long life time of the rails and bearings.

AK-T series can be equip with a laser source of 1500 watt up top 12000 watt.