Description

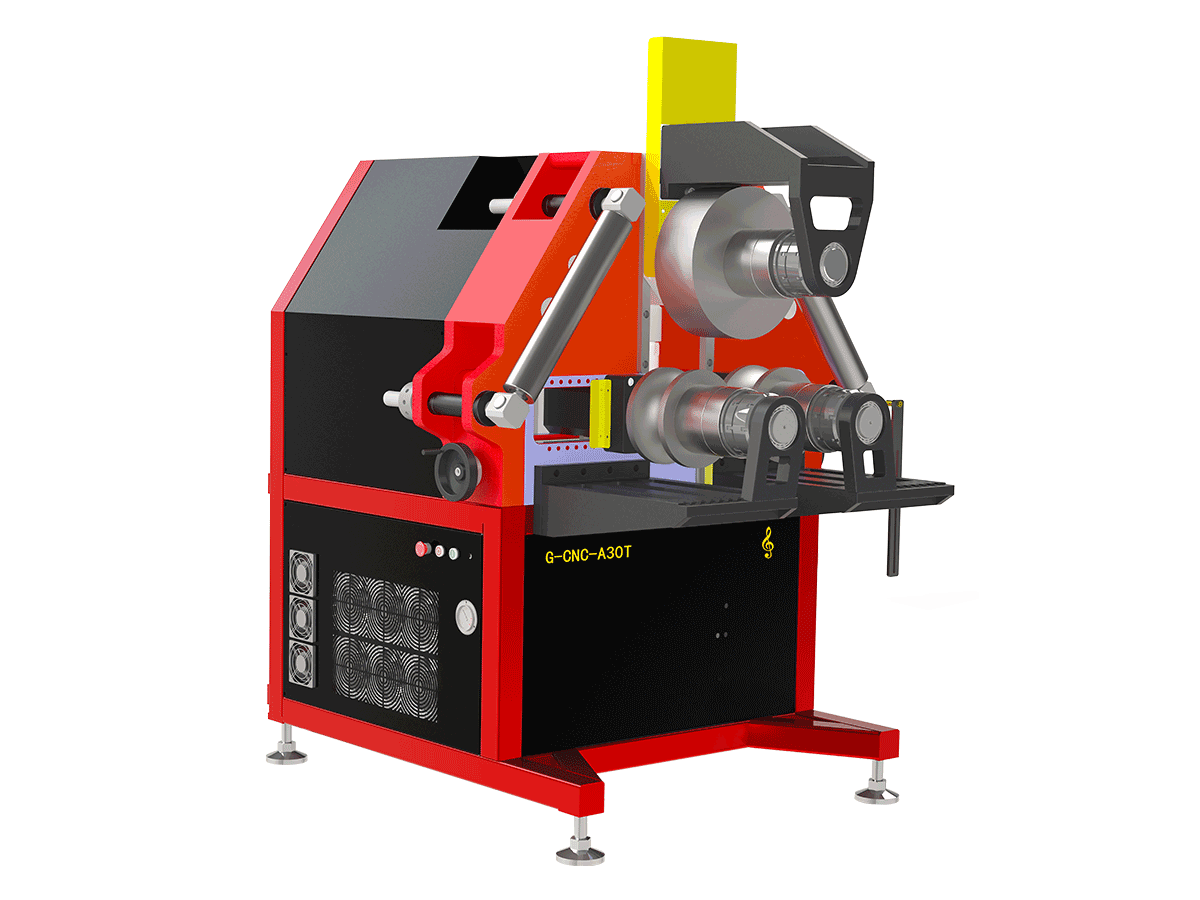

The A30T Roll Bending Machine is a high-precision G-Clef vertical CNC roll bending solution designed for versatility across multiple industries, including new energy vehicles, railway transportation, escalators, aerospace, lighting, furniture, and gym equipment manufacturing. Capable of both 2D and 3D bending, it offers manufacturers advanced flexibility while maintaining consistent, high-quality results. By utilizing a CNC control system combined with servo-drive technology, the machine minimizes reliance on operator experience and reduces labor costs, making it a smart investment for modern production facilities.

Engineered for performance, the A30T Roll Bending Machine supports profiles with a maximum cross-section area of 100x100x3 mm and achieves a minimum bending radius equal to 5-8 times the section height. Its hydraulic system delivers a powerful 30T capacity, while Y/Z-axis repositioning accuracy of 0.01 mm ensures exceptional precision. With Y/Z-axis strokes of 300/100 mm and a shaft diameter of 105 mm paired with a shaft length of 325 mm, the machine is built to handle demanding applications with ease.

The A30T Roll Bending Machine also boasts a torque of 7100 N.m, roller distances adjustable between 296 and 776 mm, and individual roller speeds ranging from 1-15 rpm with continuously variable transmission. Driven by a servo hydraulic motor, it operates on a 3-phase, 380V, 50 Hz, 20 kVA power supply. Despite its advanced capabilities, it maintains a practical footprint with overall dimensions of 1665x1250x1750 mm and a weight of 2300 kg.

By combining advanced automation, strength, and precision engineering, the A30T Roll Bending Machine provides manufacturers with a dependable and cost-effective solution for complex bending tasks across a wide range of industries.