Description

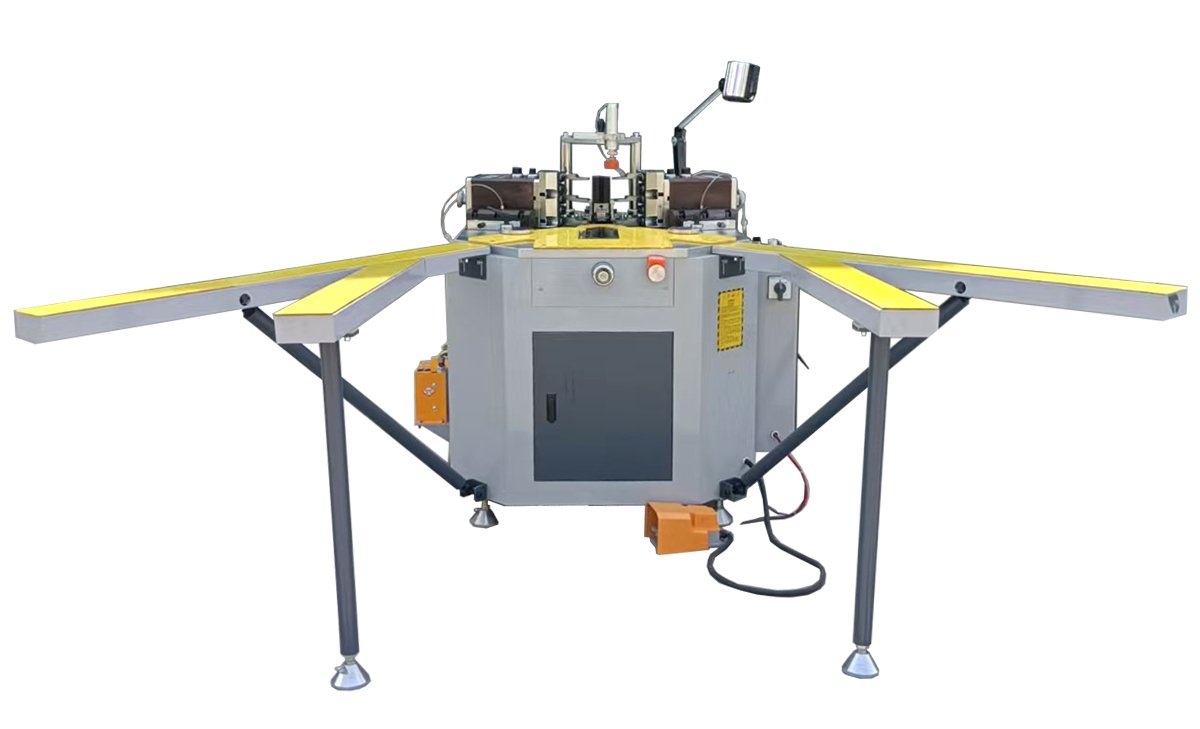

The 1 Head 150mm Corner Crimping Machine is designed for 90-degree corner combining in the production of aluminum windows and doors, delivering strong and precise connections that meet the demands of modern fabrication. Equipped with a robust hydraulic system, it provides a large punching and riveting force that ensures durability and reliability in every assembly task. This makes it a practical solution for workshops and manufacturers focused on quality and consistency in aluminum frame production.

To enhance stability and strength, the left and right punching heads of the 1 Head 150mm Corner Crimping Machine adopt a hard synchronous feeding device, creating form and uniform connections at each joint. The screw-thread adjustment mechanism regulates the distance between the upper and lower crimping blades, allowing for quick and easy fine-tuning during operation. With its advanced technique, user-friendly controls, and dependable performance, this machine simplifies the corner crimping process while reducing operator effort.

In terms of the specifications, the 1 Head 150mm Corner Crimping Machine operates with a 380V/50Hz power supply and 3 kW of power, delivering a maximum operating force of 5000 kg. It accommodates profiles up to 150 mm in height and 90 mm in width, with a minimum assembly frame size of 480×480 mm. The required air pressure is 0.5-0.8 MPa, and the machine’s overall dimensions are 2300x1200x1300 mm, offering a compact yet powerful design for a range of production setups.

By combining ease of operation, reliability, and advanced engineering, the 1 Head 150mm Corner Crimping Machine provides aluminum window and door manufacturers with a trusted solution that enhances both efficiency and connection strength.