Description

Three axis

aluminum profile cutting machine

The machine offers remote access for data transfer over Ethernet and USB connections, with a guard cabin to ensure safety in the cutting area. The machine features advanced programming capabilities and a large memory capacity. The saw blade travel speed is adjustable, and the machine can perform cutting tasks either automatically from a list or manually.

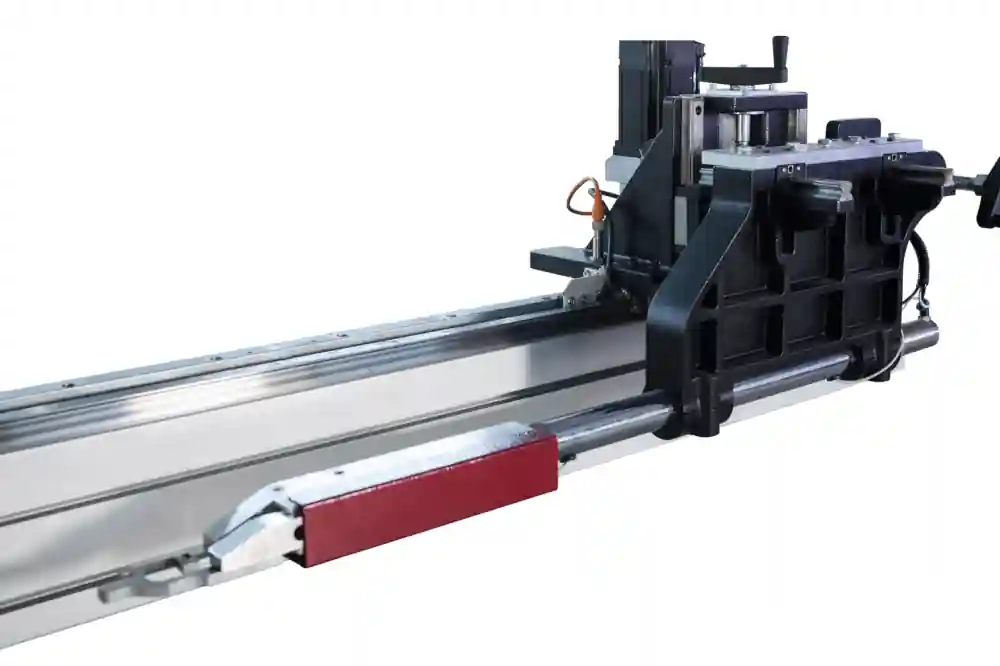

three axis aluminum cnc milling machine had been approved with additional claps for best grip of the window frame and sash profiles,

Additional support can be provided on custom models for smaller extrusion of sill or brick mould frames.

CNC milling machine is compatible with our automatic profile loader.

A discharge unit with a pneumatic conveying system allows for efficient removal of cut pieces. The machine also has a resume cutting feature that scans the cutting list and detects uncut pieces in case of emergencies, such as blackouts. The machine has the ability to send bar code information for different profile batches without the need for a cutting optimization program, and can choose profiles from the batch list for cutting.

3 axis cnc machine is nice to have equipment on the vinyl and aluminum window product.

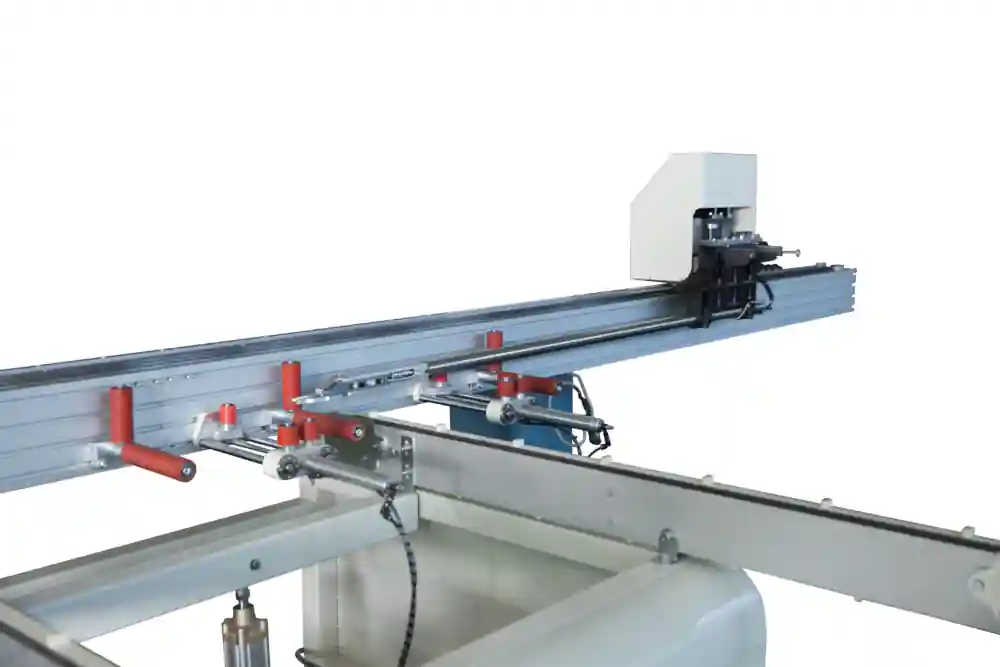

The feeding capacity for 10 profiles and high cutting capacity help increase efficiency, while high speed axis movements ensure quick and precise cutting. Additionally, the machine has automatic lubrication in the processing area for ease of maintenance.

In summary, this machine offers remote access, advanced programming capabilities, safety features, and efficient cutting with a high capacity for profiles. Its ability to perform cutting tasks automatically or manually and its resume cutting feature make it a reliable choice for businesses that require efficient and precise cutting.

with up-to ten extrusion loading in one cycle, aluminum extrusion machining with three plus one axis to get all of your performance milling, compound cutting drainage slots on the aluminum profiles.CNC control panel allows to easily same different macros for all type of window and door types. Aluminum profile CNC processing center is design for auto-feeding industrial scale profile cutting, drilling, notching for mass production.

The cutting process is controlled by a servo system, and the rotation axis is also servo-controlled. The positioning system is automated and can adjust to any angle between 30° and 150° using servo technology. To ensure precise profile positioning, there is a pneumatic holder robot with servo axis control, as well as a manual adjustment feature. The industrial PC has a user-friendly touchscreen interface that runs on Windows, making it easy to operate.

Application Area

Window and door manufacturer, store front, curtain wall fabricators, commercial aluminum suppliers, appliance suppliers, automative production, spare part manufacturers, building envelop companies, residential applications, general production where you need accurate machining every time. That machine with a fiber laser processing machine can be a great combination for industrial applications. Contact us now

Standard Equipment

21 21/34″ diamond tip saw

Automatic profile supply table

Optional Equipments

Barcode printer

Customizable X axis length

Get Your Free estimate for Saw Today

Click here to see all Aluminum Processing Machinery

More details available on the for the machinery supplier website