Have you found yourself looking for Notching Machines without being entirely sure about what they are or what they do? If your answer is yes, then you are in the right place!

In this article, we will be covering a variety of things in order to start up your understanding of Notching Machines. We will explore first and foremost, what a Notching Machine is, followed by how they work, the different types of Notching Machines, their applications, benefits, and also considerations when choosing one.

The goal here is to ensure that you are more comfortable with main elements of a Notching Machine once you reach the end of this article.

What is a Notching Machine?

Let’s start things off simple by covering what is a notch. A notch is a cut-out, an indentation, or a groove made into the edge or surface of a board. Therefore, a Notching Machine would typically be used to create a space for components or connectors, for fitting a board into housing or for assembly, to help with alignment during assembly, or simply for stress relief in structural applications.

Notching Machines are used in woodworking to cut notches into wooden pallet stringers which are essential for the assembly and the stability of pallets.

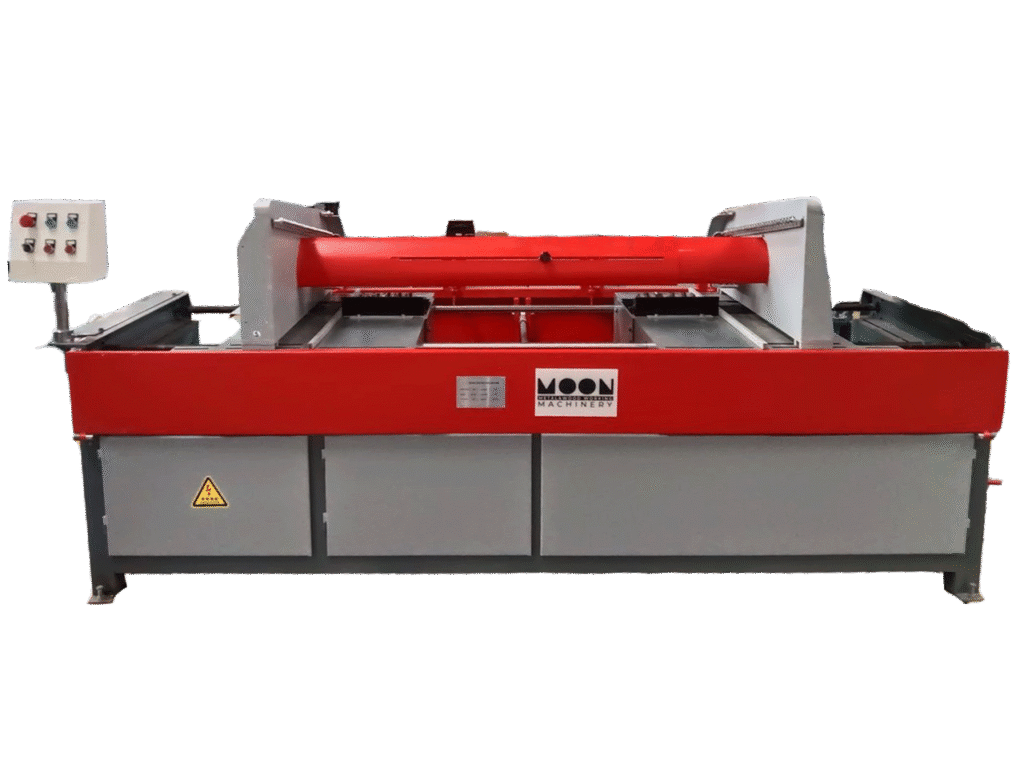

Notching Machines are also used in metalworking to create precise shapes and angles, helping with the fabrication of metal components and structures.

They help with automating the process of notching pallet stringers by making precise and consistent notches in a quick and efficient way that, in the long run, improves productivity and reduces manual labor.

How It Works

The operation of a Notching Machine starts with having a trained operator feeding the material into the machine although that process can also be automated. The material needs to be placed in the magazine, positioned against the end stops to make sure they are aligned properly. Once the material is in position, the cutting mechanism activates and notches are made according to specifications.

Notching length is adjustable, allowing for flexibility in the size and design of materials cut. This enables the Notching Machine to be used in a variety of different applications and with different specifications based on customer requirements.

Types of Notching Machines

There are many different types of Notching Machines:

Manual: These are operated by hand by a trained operator and material is manually fed into the machine. They are typically used for low volume production.

Hydraulic: These are using hydraulic power to drive the notching mechanism. Compared to manual, they have great cutting force and precision. They are typically used for medium to high volume production.

CNC (Computer Numerical Control): These are automated Notching Machines that are controlled by computer programs. The cutting parameters are programmable and offer precise positioning. Using one of these machines offers high accuracy and repeatable results. They are typically used in high volume productions and to make complex notches.

Abrasive: These use abrasive cutting wheels (or discs) that remove material from the workpiece. They are better for thick or hard materials like steel, stainless steel, and aluminum. They offer high cutting speeds and efficiency.

End Mill: These use rotating end mill cutters to create precise notches in various materials like metals, plastics, and composites. They are typically used in machining and fabrication shops.

Punch: These used punch and die sets that can handle a variety of materials and thicknesses. They are typically used in sheet metal fabrication and offer high speed operation.

For woodworking applications, more specifically, there are 4 different types:

Single-Head Notching: They have a single cutting head and are commonly used in low to medium production environments.

Double-Head Notching: They have two cutting heads, which increases productivity and efficiency, making them suitable for higher production.

Adjustable Notching: They allow for increased flexibility in the size and design of the notches. They can also accommodate for different pallet specifications and customer requirements because of the notching length being adjustable.

Chamfering Notching: They have a chamfering attachment which allows for chamfering or beveling to be done during production, increasing versatility.

Applications

Notching Machines can be used in a variety of different applications.

In the fabrication of metal frames and structures, they notch metal tubes, pipes, profiles for the assembly of frames, structures, and frameworks in construction and manufacturing.

In the production of metal brackets and fittings, they make precise notches and cutouts in the metal brackets, fitting, and hardware.

In the fabrication of sheet metal, they notch and cut sheet metal panels and plates in order to create joints, tabs, and flanges.

In automotive and aerospace manufacturing, they help with the production of automotive chassis, aircraft frames, and other specialized components that need precise notches and cutouts.

Benefits

Owning Notching Machines have multiple benefits. You can enjoy increased efficiency since automating the notching process not only reduces the time required to notch but also the effort it takes, compared to manual. Automating the notching process also improves precision and ensures that notches stay consistent, that way workpieces stay uniform and the overall quality improves. You would also be saving on labor costs because automating the process would reduce the need for manual labor as it also increases overall productivity.

Considerations When Choosing One

When choosing between Notching Machines, here is a list of things you should consider:

- Material type & thickness range: What your parts require determines the machine power and strength.

- Precision & tolerance: How tight the notch tolerances must be.

- Notch geometry: Notch depth, width, angles, and whether they’re adjustable.

- Feed/automation: Do you need manual, semi-automatic, or fully automatic feed and positioning?

- Tooling & changeover: For the ease of changing cutters, dies, and the tooling cost.

- Machine rigidity & durability: This is to maintain accuracy while under load.

- Safety & guarding: This is especially necessary with hydraulic or mechanical systems.

- After-sales support: You will need maintenance, service, and spare parts.

- Integration ability: Linking it with a CNC, data systems, and automation.

- Cost vs ROI (return of investment): What is the initial investment, the operating cost, and throughput.

Conclusion

In conclusion, Notching Machines play a vital role in both woodworking and metal fabrication by combining precision, speed, and efficiency. Whether cutting pallet stringers, shaping metal frames, or preparing components for assembly, these machines simplify complex processes while improving consistency and reducing manual labor. With options ranging from manual to CNC-controlled systems, each type offers unique advantages to match production needs and material requirements. Selecting the right Notching Machine depends on factors such as material thickness, precision, automation level, and long-term reliability. When chosen carefully, a Notching Machine becomes an invaluable investment, boosting productivity, ensuring accuracy, and supporting the growth of any modern manufacturing operation.

Check out our notching machines for woodworking here.

References

KRRASS. (2024, March 18). Notching Machines: Definition, applications, types, and working principle. Retrieved October 17, 2025, from https://www.bestsheetmetalmachine.com/what-is-a-notching-machines/

ZZCHRYSO. (2024, March 5). What is a wood pallet notcher machine and how does it work? Retrieved October 17, 2025, from https://www.wood-pallet-machine.com/what-is-a-wood-pallet-notcher-machine-and-how-does-it-work/