For any aluminum window and door industry, having the right machinery is essential for completing projects quickly, accurately and efficiently. That’s why the evolution fiber laser processing machine is the perfect tool for the job. This high-precision machine is designed to optimize the efficiency of aluminum window and door production by delivering a range of benefits to businesses. With its state-of-the-art laser processing technology, the machine can quickly and accurately cut aluminum profiles, ensuring that projects are completed to the highest quality standards. It also offers greater flexibility, allowing businesses to adjust the parameters of the cutting process to suit the specific requirements of each project. Furthermore, its intuitive user interface means that it’s easy to operate and requires minimal training, reducing downtime and increasing production throughput. With the evolution fiber laser processing machine, businesses can benefit from faster, more accurate production of aluminum windows and doors.

Benefits of evolution fiber laser processing machine

The evolution fiber laser processing machine offers numerous benefits to businesses in the aluminum window and door industry. Firstly, it can significantly reduce cutting times, so projects can be completed more quickly and efficiently. It also has the ability to process thicker aluminum materials, allowing businesses to take on more challenging projects. This can help improve the quality of products, as thicker materials provide greater strength and rigidity. Additionally, the evolution fiber laser processing machine is more precise than traditional methods, helping to reduce the risk of errors. This means that finished products are more accurate and will therefore provide greater strength and durability. In addition, the evolution fiber laser processing machine offers greater flexibility, allowing businesses to adjust the parameters of the cutting process to suit the specific requirements of each project. This can result in improved quality and consistency across different parts. Moreover, its intuitive user interface makes it easy to operate, reducing the need for training and increasing productivity. The evolution fiber laser processing machine can therefore deliver significant benefits to businesses in the aluminum window and door industry.

Features of evolution fiber laser processing machine

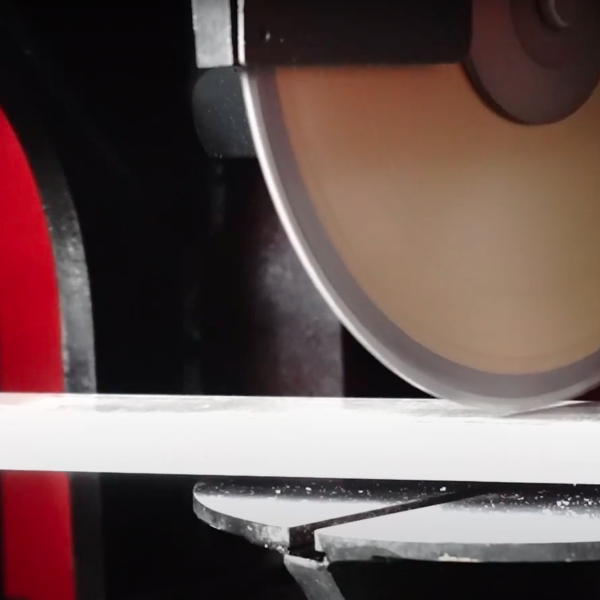

The evolution fiber laser processing machine is an efficient, high-precision tool for the efficient processing of aluminum profiles. It leverages the advantages of fiber laser technology to deliver greater precision, reduced cutting times and greater flexibility. This machine boasts a cutting accuracy of +/- 10 microns and a cutting speed of approximately 10-15 seconds per cut. It offers a wide range of aluminum processing materials, including alloys, coated materials and high-quality uncoated materials. Furthermore, the evolution fiber laser processing machine is designed with a compact and space-saving design, making it suitable for use in a variety of settings. It features an intuitive user interface, so it’s easy to operate and requires minimal training. This machine offers businesses in the aluminum window and door industry a range of benefits.

How evolution fiber laser processing machine is used

The evolution fiber laser processing machine is ideal for cutting a range of aluminum profile materials. The materials are placed on the machine’s conveyor belt, where they are automatically moved into position. When the machine is ready to start cutting, the operator presses a button to begin the process. The machine automatically detects the position of the material and begins cutting. At the end of the process, the operator removes the parts from the machine and loads the next materials onto the conveyor belt. The evolution fiber laser processing machine is a very flexible machine. The operator can manually adjust the parameters of the cutting process to suit the specific requirements of each project. This can help businesses to produce parts to the highest quality standards. The evolution fiber laser processing machine offers businesses in the aluminum window and door industry a range of benefits.

Advantages of FHBS fiber laser processing machine

The FHBS fiber laser processing machine offers an extensive range of benefits to businesses in the aluminum window and door industry. Firstly, it can significantly reduce cutting times, so projects can be completed more quickly and efficiently. It also has the ability to process thicker aluminum materials, allowing businesses to take on more challenging projects. This can help improve the quality of products, as thicker materials provide greater strength and rigidity. Additionally, the evolution fiber laser processing machine is more precise than traditional methods, helping to reduce the risk of errors. This means that finished products are more accurate and will therefore provide greater strength and durability. In addition, the evolution fiber laser processing machine offers greater flexibility, allowing businesses to adjust the parameters of the cutting process to suit the specific requirements of each project. This can result in improved quality and consistency across different parts. Moreover, its intuitive user interface makes it easy to operate, reducing the need for training and increasing productivity. The evolution fiber laser processing machine can therefore deliver significant benefits to businesses in the aluminum window and door industry.

Disadvantages of evolution fiber laser processing machine

The evolution fiber laser processing machine is an advanced piece of equipment that delivers significant benefits to businesses in the aluminum window and door industry. However, it does have a higher upfront cost than some other machines. In addition, the machine can be difficult to move between locations due to its size and weight. Furthermore, the evolution fiber laser processing machine may not be suitable for smaller businesses, as it requires a high level of maintenance to operate at peak performance. Overall, the evolution fiber laser processing machine delivers significant benefits to businesses in the aluminum window and door industry. However, it does have a few disadvantages.

Applications of evolution fiber laser processing machine

The evolution fiber laser processing machine is a versatile piece of equipment that can be used for a range of different applications in the aluminum window and door industry. It can be used to process a wide range of aluminum profiles and materials, including alloys, coated materials and high-quality uncoated materials. This machine can also be used to process a range of different types of metals, such as stainless steel, copper and brass. Overall, the evolution fiber laser processing machine is a versatile machine that can be used for a wide range of applications in the aluminum window and door industry.

Cost of evolutionary fiber laser processing machine

The evolution fiber laser processing machine is an advanced piece of equipment that delivers significant benefits to businesses in the aluminum window and door industry. It is designed for high-end applications and therefore comes at a higher price than other machines. This machine is suitable for businesses that need to produce high-quality products quickly and efficiently. The evolution fiber laser processing machine is a robust and reliable machine that offers impressive benefits to businesses in the aluminum window and door industry.

Conclusion

The fiber laser processing machine is a robust and reliable machine that delivers significant benefits to businesses in the aluminum window and door industry. It is designed for high-end applications and comes at a higher price than other machines. This machine is suitable for businesses that need to produce high-quality products quickly and efficiently. The evolution fiber laser processing machine is a robust and reliable machine that offers significant benefits to businesses in the aluminum window and door industry. Laser machines already took place for many application areas for heavy to heavier industrial application with high power version,

I believe now it is time for the window and door manufacturers to consider that new technology which is going to provide faster processing for lower cost.