Do you not know what a CNC Press Brake is? Not sure if you would need it either for your current or future manufacturing business? In this article, we can help begin your understanding of CNC Press Brakes.

We will highlight the main question of what a CNC Press Brake is, how they work, their advantages, different types of Press Brakes, their applications, as well as considerations when choosing one.

Our goal at the end of this is to have you know more about both what CNC Press Brakes are and what they do, along with being more confident in what you might be looking for.

What is a CNC Press Brake?

Let’s start off with breaking down the terms.

CNC stands for Computer Numerical Control. This means that the machine tools are automated through computer-executed commands. Through the computer, you can control the movement, speed, and operational sequence of machine tools.

As for “press”, in 1300, the word “presse” was used as a noun meaning to crush or crowd. In the 14th century, the word “press” meant a device for pressing clothes or squeezing out juice. However, now, “press” means a machine or mechanism that applies force by squeezing.

The word “brake”‘s 15th century definition was an instrument used for crushing or pounding. Eventually, “brake” became synonymous with “machine” which means that saying press machine is the same thing as press brake.

Therefore, a CNC Press Brake is a pressing machine controlled by a computer that uses its pressing power to bend or fold sheet metal.

A CNC Press Brake does not need an operator with a particularly high skill level. They also are amongst the most precise bending machines while also having a wide material thickness range (0.5mm up to 20mm). This type of Press Brake does need a high maintenance frequency but they have a very high production speed equaling in a high daily capacity.

How It Works

Let’s take a look at a CNC Press Brake’s key components:

The Ram applies the pressure. The Bed supports the material. The Dies shape the material. The Backgauges ensure precise positioning. The Frame provides structural integrity to the machine. Finally, the CNC Controller manages all of the machine’s functions and programming, and is able to store hundreds of programs for instant recall.

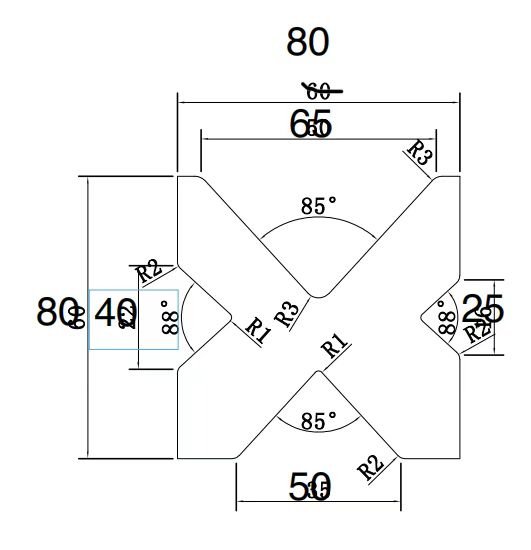

Now that we’ve got the basic components established, we’ll dive a little deeper on the Dies.

The male die, also called the upper tool or punch, is secured to the Ram of the Press Brake. It experts a controlled force onto the workpiece, which drives it into the female die in order to create the desired shape. There are multiple types such as straight punches, gooseneck punches, hemming punches, and rotational punches.

The female die, also called the lower tool, is secured to the Bed of the Press Brake. It provides a precisely shaped groove that matches the male die’s geometry and accommodates the material during the bending process. The different types are V-shaped dies, U-shaped dies, offset dies, and adjustable dies.

Advantages

The main advantages of CNC Press Brakes are their consistency and repeatability, their high precision, their ability to create complex parts, reduced human error due to the use of a computer to not only program the machine but also store hundreds of programs, as well as the fact that they are automated which increases productivity.

Types of Press Brakes

The four main types of press brakes are Manual, Electric, Hydraulic, and CNC. However, since we are covering CNC Press Brakes throughout this whole article, let’s focus on the other three in this section.

Manual Press Brakes need an operator with a higher skill level than the other types because there is no help or support from a computer, electricity, or hydraulics. By choosing Manual, there is a lower bending accuracy, and they have a lower production speed.

However, they are more cost effective than other types and lower maintenance. If your business does not require a press brake for everyday production and you would rather spend your funds elsewhere, a Manual Press Brake would be ideal.

Electric Press Brakes are made for thinner metal sheet bending of 0.5mm up to 6mm and due to their electric nature, they do not require a skilled operator in order to have good results. They are the quietest Press Brakes of the 4, are very precise, highly energy efficient and low maintenance.

If your business deals in bending thinner metal sheets and prefer a quieter, energy efficient solution while still being precise, an Electric Press Brake is the best choice.

Hydraulic Press Brakes use fluid pressure to create force to bend sheets of metal. Therefore, they are best for thicker materials from 6mm up to 25mm. Although the operator does not need a high skill level, they do need to be relatively skilled to operate this type of press brake.

They are not made to be energy efficient and do not produce at high speeds but they are necessary for thicker sheets of metal used in applications such as shipbuilding.

Applications

CNC Press Brakes are generally very precise and consistent machines. Therefore, the industries where they would be best applied would be industries where precision and consistency are needed, such as electronics, automotive, metal fabrication, and even aerospace.

Considerations When Choosing One

Before buying a CNC Press Brake, consider these factors:

- Production Volume: If your business has a high production volume, the CNC Press Brake is the best option.

- Material Thickness: CNC Press Brakes can handle material thicknesses from 0.5mm up to 20mm. So, if the material you are working with is thicker, consider a Hydraulic Press Brake instead since they can handle thicknesses from 6mm up to 25mm.

- Automation Needs: If you require precision and efficiency, CNC or Electric Press Brakes would be the better choices.

- Energy Consumption: Electric or Manual Press Brakes are the most energy efficient options.

- Bending Accuracy: If your production requires a high bending accuracy, the CNC Press Brake is the best option.

Conclusion

In the end, understanding what a CNC Press Brake is and how it differs from other types of Press Brakes comes down to matching its strengths to your production needs.

CNC Press Brakes combine automation, precision, and speed, making them an excellent choice for high-volume manufacturing and can store countless programs for quick changeovers, which helps reduce downtime and human error.

Other options such as manual, electric, and hydraulic press brakes each have their own advantages in certain applications. However, a CNC Press Brake stands out when efficiency, versatility, and consistent results are top priorities.

By considering factors such as your production volume, material types, energy usage, and desired accuracy, you can determine whether a CNC Press Brake stands is the right fit for your current or future operations.

With the right choice, you can improve productivity and position your business for more efficient, precise, and competitive manufacturing.

If you are looking for more information, do not hesitate to contact us here.

References

ADH Shop. (2025, July 7). Understanding Press Brakes: Types, functions, and applications – ADH Machine Tool. ADH Shop. Retrieved August 11, 2025, from https://shop.adhmt.com/press-brake/

Benson, S. (2023, May 18). What Is A Press Brake and Where Did the Name Come From? The Fabricator. Retrieved August 11, 2025, from https://www.thefabricator.com/thefabricator/article/bending/what-is-a-press-brake-and-where-did-the-name-come-from

Graf, D. (2024, November 19). Understanding the different types of press brake machines. Mac-Tech. Retrieved August 11, 2025, from https://mac-tech.com/metal-fab-equip/understanding-the-different-types-of-press-brake-machines/

LeTang, P. (2020, January 4). Understanding modern press brakes. The Fabricator. Retrieved August 11, 2025, from https://www.thefabricator.com/thefabricator/article/bending/understanding-modern-press-brakes

Team, F. (2025, March 11). Explore Different Types of Press Brakes & Technology. Fab-Line Machinery. Retrieved August 11, 2025, from https://www.fab-line.com/news/a-guide-to-the-different-types-of-press-brakes/

Weiya. (2025, May 6). Types of Press Brakes: CNC, Hydraulic & Electric Compared – Weiya Machinery Technology Co., Ltd. Weiya Machinery Technology Co., Ltd. Retrieved August 11, 2025, from https://www.weiyamt.com/types-of-press-brakes-cnc-hydraulic-electric-compared/#External_Links