Description

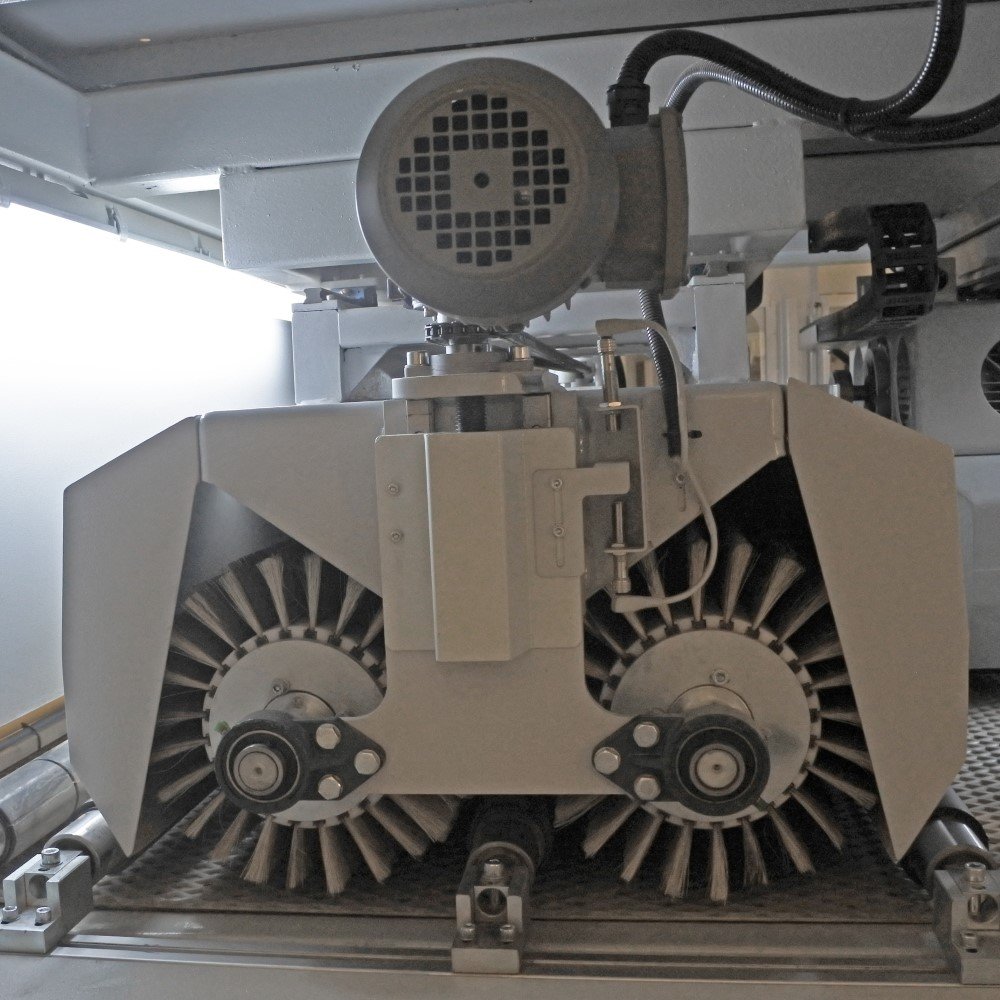

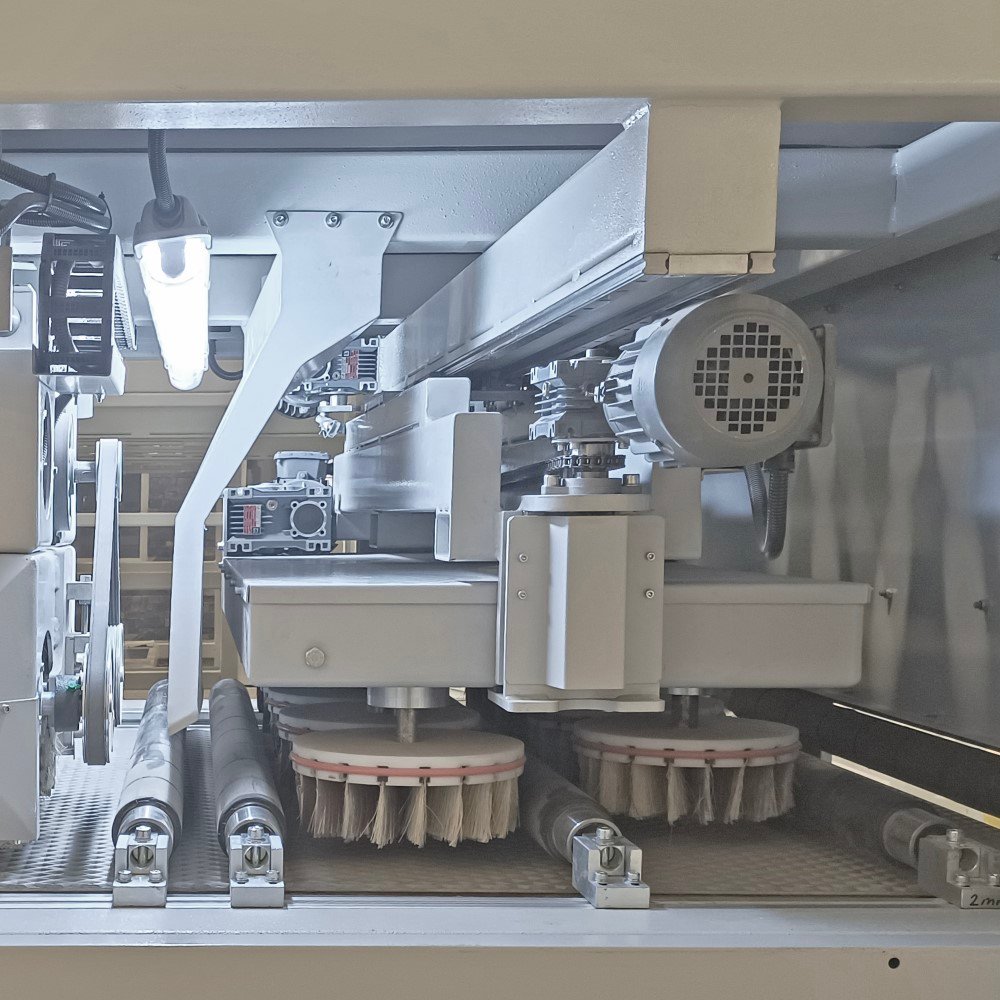

The Brush Sanding Machine KR FZM 1300-1.1 is advance machine of the previously designed model. This Brush Sanding Machine KR FZM 1300-1.1 us developed for 3D raw and primer sanding of rustic and CNC carved surfaces, achieves successful results even on the most demanding surfaces with its flexible sanding feature. Primer sanding is perfectly done in to the every edge and corner. Thanks to the oscillating brush sanding unit, which works perpendicular to the horizontal axis, it allows you to get the best result by sanding uniformly on all surfaces. The sanding machine offers its user high quality and economical surface sanding opportunities even on very difficult products with its standard features which do not exist in many machines.

This unit consists of 9 oscillating brush sanders with automatic adjustment of height, speed and direction. It is extremely successful in raw and primer sanding of carvings on the product. Easily replaced brushes provide convenience to the operator. Its ability to rotate both sides allows the use of different grits on 2 surfaces.

Area of Usage

The Brush Sanding Machine KR FZM 1300-1.1 is used as an entry door sanding machine, interior door sanding, cabinet sanding machine and all kind of panel furniture.

Click here to see all sanders.

canada, toronto, moon machinery, kama, karabudak machine, edge sanding machine, edge sander, spray coating machine, spray coater, oscillating system edge sander, drying systems, dry booths, furniture spraying, coating, brush sanding machine</p