Description

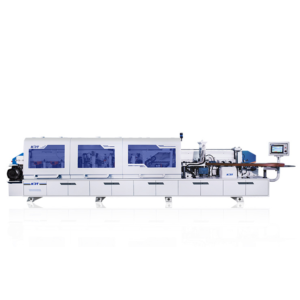

Product Description: Double-Rail End Cutting Edge Banding Machine KE-386D

Double-Rail End Cutting Edge Banding Machine KE-386D Features: Enhancing Wooden Door Edges with Precision and Efficiency

Double-Rail End Cutting Edge Banding Machine KE-386D Key Mechanisms:

- Dual Guide Rails: A double-rail system ensures superior precision in end cutting.

- Rough and Fine Finishing: Incorporates mechanisms for both rough and fine finishing, achieving optimal edge quality.

- Edge Scraping: Equipped with an edge scraping mechanism to prevent glue accumulation and maintain optimal performance.

Double-Rail End Cutting Edge Banding Machine KE-386D Advantages:

- Enhanced Panel Pressing: The wide contact area of the track press guarantees effective panel pressing, ensuring stable conveyance and superior edge sealing quality.

- Efficient Glue Application: Features a large glue pot for rapid melting and automatic addition of glue particles, ensuring a consistent and ample supply of adhesive.

- Bonding Strength: A five-wheel press enhances edge bonding, while each wheel integrates a scraper mechanism to prevent glue buildup on the pressing surface.

Edge Tech’s Commitment: Flexibility and Intelligent Production A recognized trailblazer in edge bander technology, we prioritize meticulous attention to detail and dedicate ourselves to continuous innovation and research and development. By incorporating internationally advanced techniques and key components from leading brands, we strive to provide global customers with unparalleled, high-quality products.

Complete Solution for Intelligent Furniture Production Across the Home

Technical Specifications:

- Model: KE-386D

- Feeding Speed: 15-23 m/min

- Tape Thickness: 0.4-3 mm

- Panel Thickness: 9-60 mm

- Panel Length: ≥120 mm

- Panel Width: ≥90 mm

- Min. Panel Size: 120 mm x 90 mm

- Total Power: 23.33 kW

- Overall Size: 7346 mm (L) x 830 mm (W) x 1960 mm (H)

- Dust Hood Size & Quantity: Ø100 mm x 2 + Ø125 mm x 5

For Precision, Efficiency, and Quality in Wooden Door Edge Enhancement, Choose Model KE-386D. Experience the Future of Intelligent Furniture Production.