Description

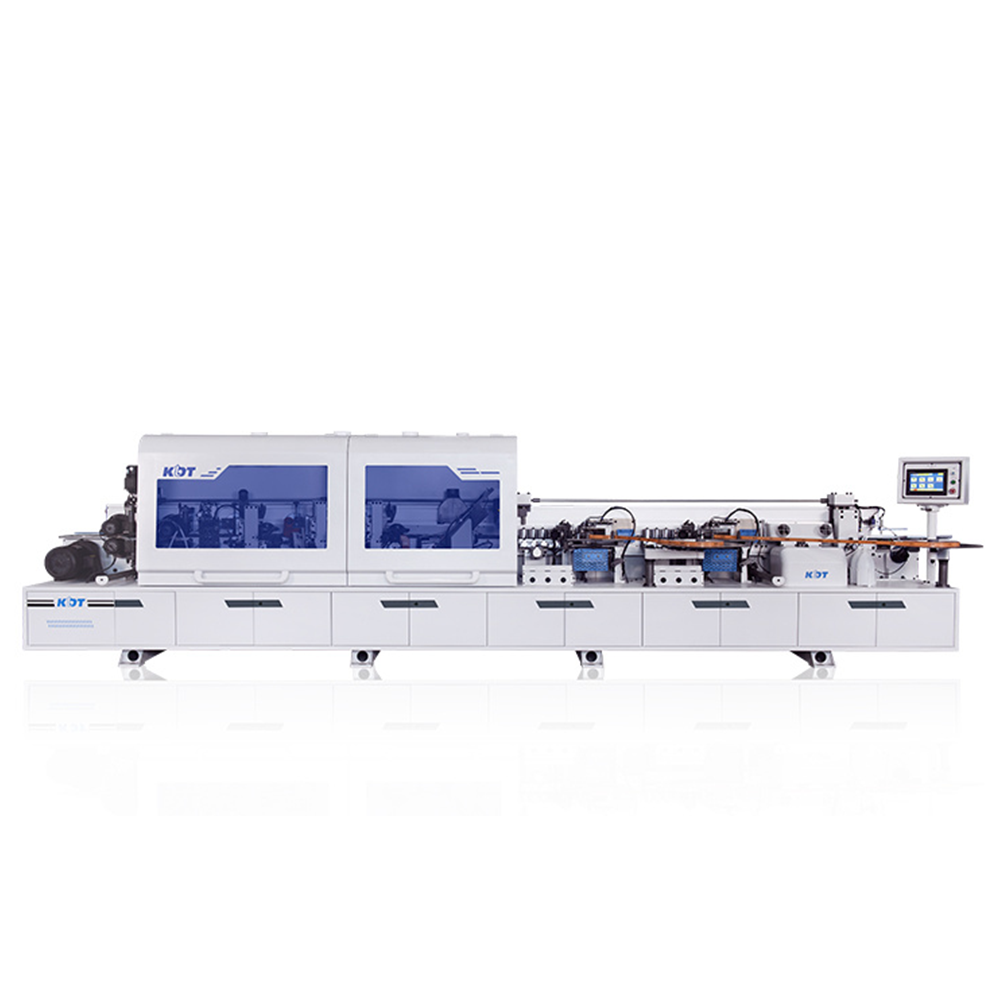

Rough Trim Unit Edge Banding Machine KE-368JSG

Pre-Milling with Dual Glued Pressing: Reciprocal Action Advantages of the Rough Trim Unit Edge Banding Machine KE-368JSG:

- Enhances bond integrity and aesthetics by employing dual milling cutters to rectify corrugated traces, burrs, or irregularities resulting from the cutting process. This tighter bond between edge banding strip and plate improves overall appearance.

- Incorporates a preheating mechanism that facilitates adhesive adherence to the board. Instant heating upon contact with the board reduces energy consumption while enhancing edge banding efficiency.

- Trims surplus edge banding extending beyond the upper and lower edges of the wooden board. This results in a flush alignment between the edge banding and the wooden board’s upper and lower surfaces.

- Features a pneumatic control system tailored to custom furniture production. The system adapts automatically to different edge banding thicknesses (selectable via a touch screen), thus boosting production efficiency. Cutting-Edge Technology for Enhanced Flexibility and Intelligent Manufacturing Renowned for our pioneering role in the edge bander sector, we prioritize meticulous attention to detail and continually invest in innovation and research and development. Aligned with customer requirements, KDT integrates cutting-edge international technology and premium components from leading brands, with the goal of offering globally superior products. Comprehensive Solution for Smart Home Furniture Production

Rough Trim Unit Edge Banding Machine KE-368JSG Technical Specifications:

Model: KE-368JSG

Feeding Speed (m/min): 15-23

Tape Thickness (mm): 0.4-3

Panel Thickness (mm): 9-60

Panel Length (mm): ≥120

Panel Width (mm): ≥85

Minimum Panel Size (mm): 12085

Total Power (kW): 25.89

Overall Dimensions (LxWxH) (mm): 6782L830W1700H

Dust Hood Size & Quantity: φ1002+φ125*3