Description

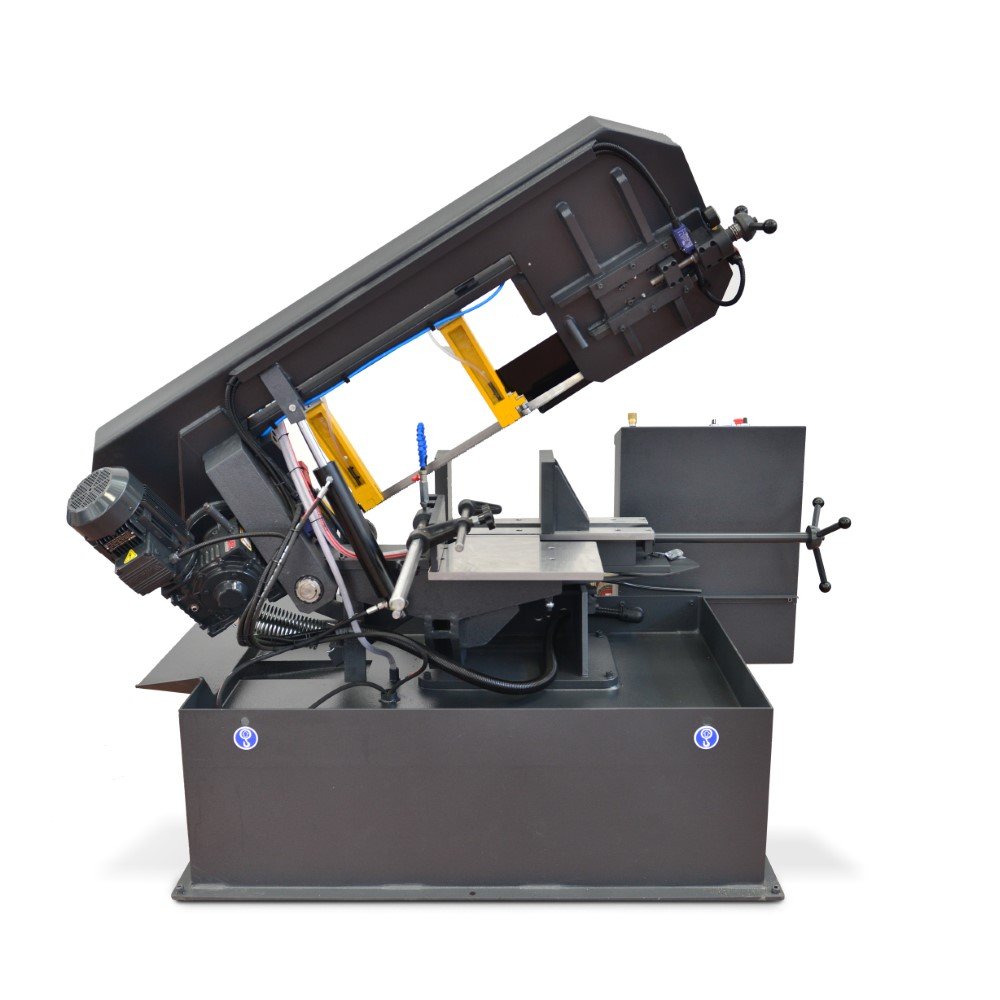

The Manual Horizontal Bandsaw Machine BMS-320G is a robust and reliable cutting solution built for universal separation of full materials, pipes, and profiles. Known for its stable construction and ease of use, the Manual Horizontal Bandsaw Machine BMS-320G is especially effective in workshops where dependable and precise cutting is essential. One of its defining features is the fast and accurate mitre adjustment, which allows users to make angled cuts ranging from 90 degrees to 30 degrees with minimal effort and maximum precision.

The Manual Horizontal Bandsaw Machine BMS-320G has a cutting operation that remains in-line, with manual strain applied at the 90-degree position. The machine is designed for intuitive functionality while offering high performance in daily use. Equipped with a removable coolant tank and a submerged electric coolant pump, it ensures continuous cooling during operation, delivering coolant to both blade guide assemblies for optimal blade longevity and cutting accuracy.

Blade guides, constructed with rollers and carbide pads, provide form and accurate blade support–resulting in clean, consistent cuts across various materials. The Manual Horizontal Bandsaw Machine BMS-320G includes built-in safety features like thermal overload protection and a no-volt release system. Once a cut is complete, the machine automatically shuts off, enhancing operator safety and conserving energy.

Each unit comes standard with a bi-metal saw blade and a 47 1/4″ infeed roller table (1200mm), adding to the machine’s value and functionality. Choose the Manual Horizontal Bandsaw Machine BMS-320G for a dependable, cost-effective cutting tool that delivers superior results over time.

Click here to see all horizontal bandsaws.