Description

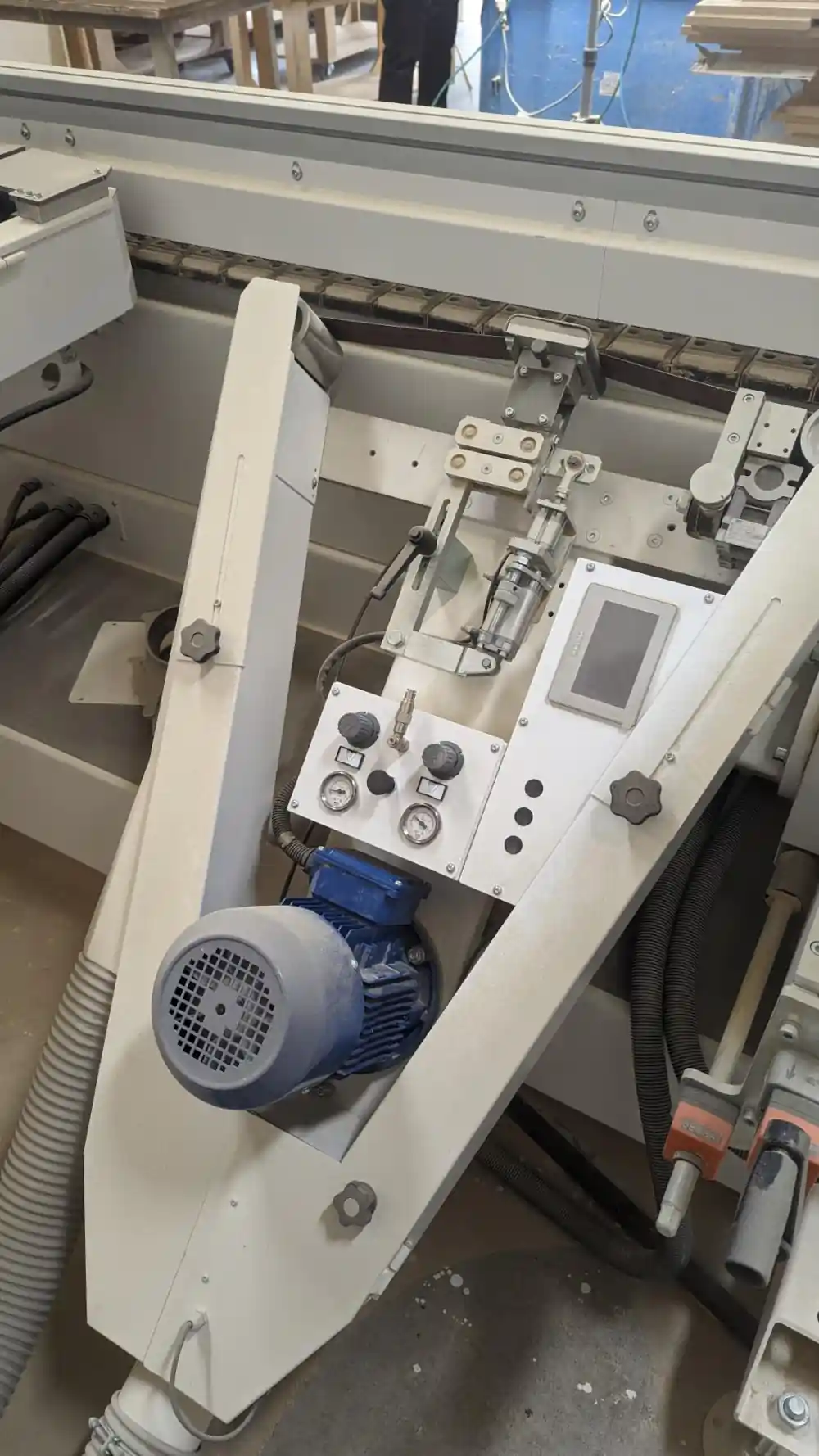

The Used Edge Sanding Machine is designed for efficiency and precision, featuring a continuous belt forward feed system. Workpieces move smoothly along a chain guided by a circular track and rubber plugs, all powered by a motor with adjustable speed ranging from 6 to 30m/min.

Thanks to specially shaped pads, even highly complex workpieces can be sanded effectively using abrasive belts. The Used Edge Sanding Machine adapts to intricate profiles without compromising quality.

To ensure optimal results, all materials used to manufacture the sanding pads–such as rubber, felt, graphite cloth, and select metals–have been extensively tested in-house. Each material is carefully chosen based on the profile’s shape and the wood’s characteristics. With its reliable performance and adaptability, the Used Edge Sanding Machine is a valuable asset for professional woodworking environments.

Used Edge Sanding Machine Technical Data

- Manual pressure wheel lifting

- Side support for wide panels on fitting stand

- Working height 34.25″

- PLC TOUCH SCREEN WITH COMMANDS ON BOARD MACHINE for automatic management of the following

functions:- Pads and blowers timed entry/exit unit

- The feed speed of the track

- The intervention of the blower to clean the belt

- ON/OFF of the blower to clean the belt

- The number of rounds of the sanding wheel

- The recovery of the sanding wheel

- The sanding wheel timed entry

Used Edge Sanding Machine WORKING UNITS:

Unit 1

1) T2Z009A – N90/P – Belt sanding unit for flat surfaces up to 3.34″. max. width

• Belt oscillation and centring device located on the front pulley to allow

adjustments in total safety even during working process.

• Safety switch in case of belt breaking, with releasing of pad and stop of

feeding.

• Blowers for belt cleaning and cooling, synchronized with the pad entry.

• Position mechanical readouts on three adjustment axes of the unit (horizontal,

vertical inclination)

• Belt size 118.11″ x 3.54″

• KW. 2.2 motor inverter controlled

• Unit tiltable from; – 30° + 100°

• Nr. 2 – Extraction hoods 2 3.93″.

• Extraction rate 1400 m°/hr at 25 m/sec.

• Compressed air consumption 240 V/min.

The Toronto owner simply doesn’t need the automatic edge sander anymore.

Click here to see all used machines.

canada, moon machinery, toronto, used machine form turkish dealer, used machines, turkish dealer, fiber laser cutting machines, solid tube cutting, metal sheet cutting, cutting, laser cutting, second hand machine, second hand ontario