Description

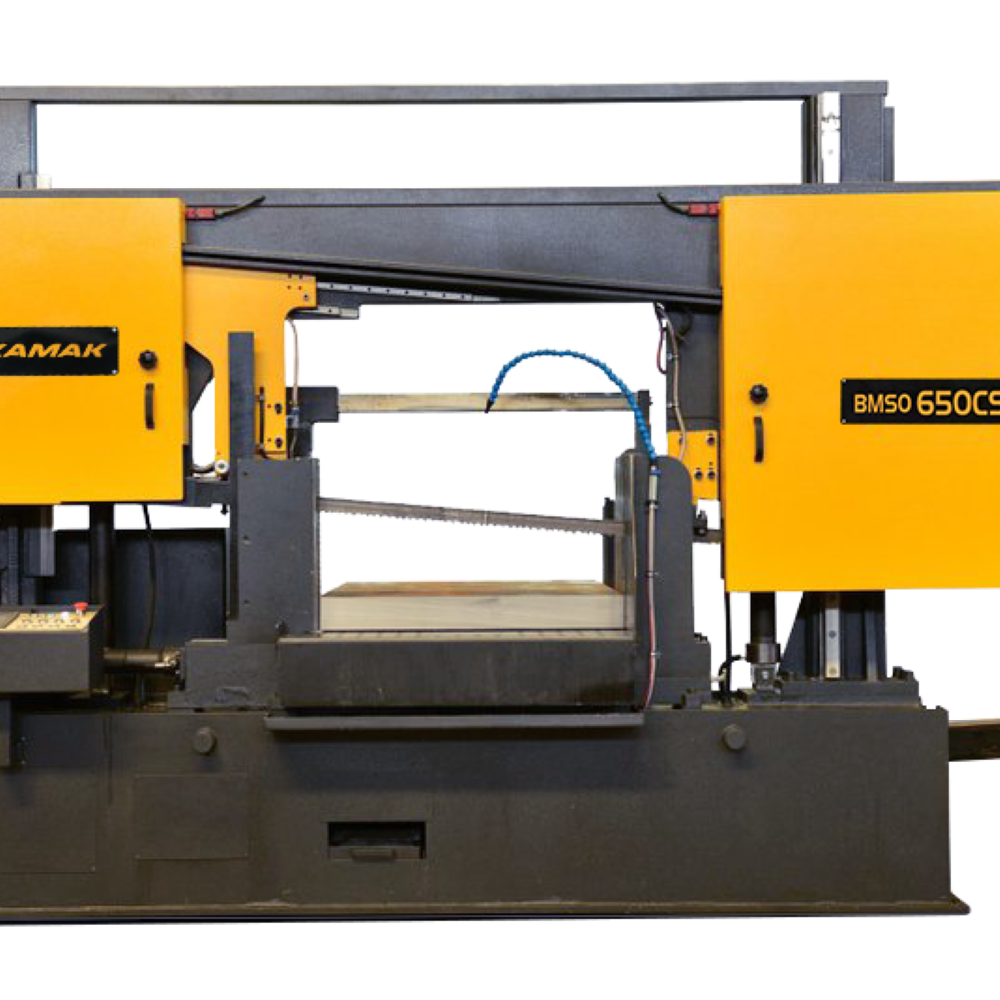

The Fully Automatic Drive Machine Twin Pillar Saw BMSO-650CS NC is expertly built for high-volume, high-precision cutting of heavy metals, pipes, and structural profiles. Designed to enhance productivity with minimal operator input, this advanced machine is equipped with a fully automatic servo feeding system, delivering fast and repeatable results across continuous production cycles.

At the heart of this model is a user-friendly Omron touchscreen control panel, offering operators intuitive access to powerful programming features. You can store up to 50 cutting steps across 30 unique programs, making it easy to switch between jobs and maintain workflow efficiency. Its servo-driven feeding mechanism includes a 27 9/16″ (700mm) stroke and 3/8″ (10mm) multiple stroke functionality, ensuring precise control of cutting lengths.

The twin column design and dual linear guideways reduce vibration during operation, ensuring smoother cuts and increased blade life. An automatic deflection sensor provides intelligent compensation for material resistance, maintaining accuracy even with thick or irregular stock.

Additional features include a chip conveyor for clean operation, a planetary gearbox for high-efficiency torque transfer, and an overall design optimized for durability and consistent output. Whether cutting solid bars, heavy tubes, or steel profiles, the Fully Automatic Drive Machine Twin Pillar Saw BMSO-650CS NC offers the precision and performance needed in demanding industrial applications.

With advanced automation, intelligent monitoring, and robust construction, this saw is a smart investment for metalworking professionals aiming to scale operations without compromising on quality.

Click here to see all drive machines.