Description

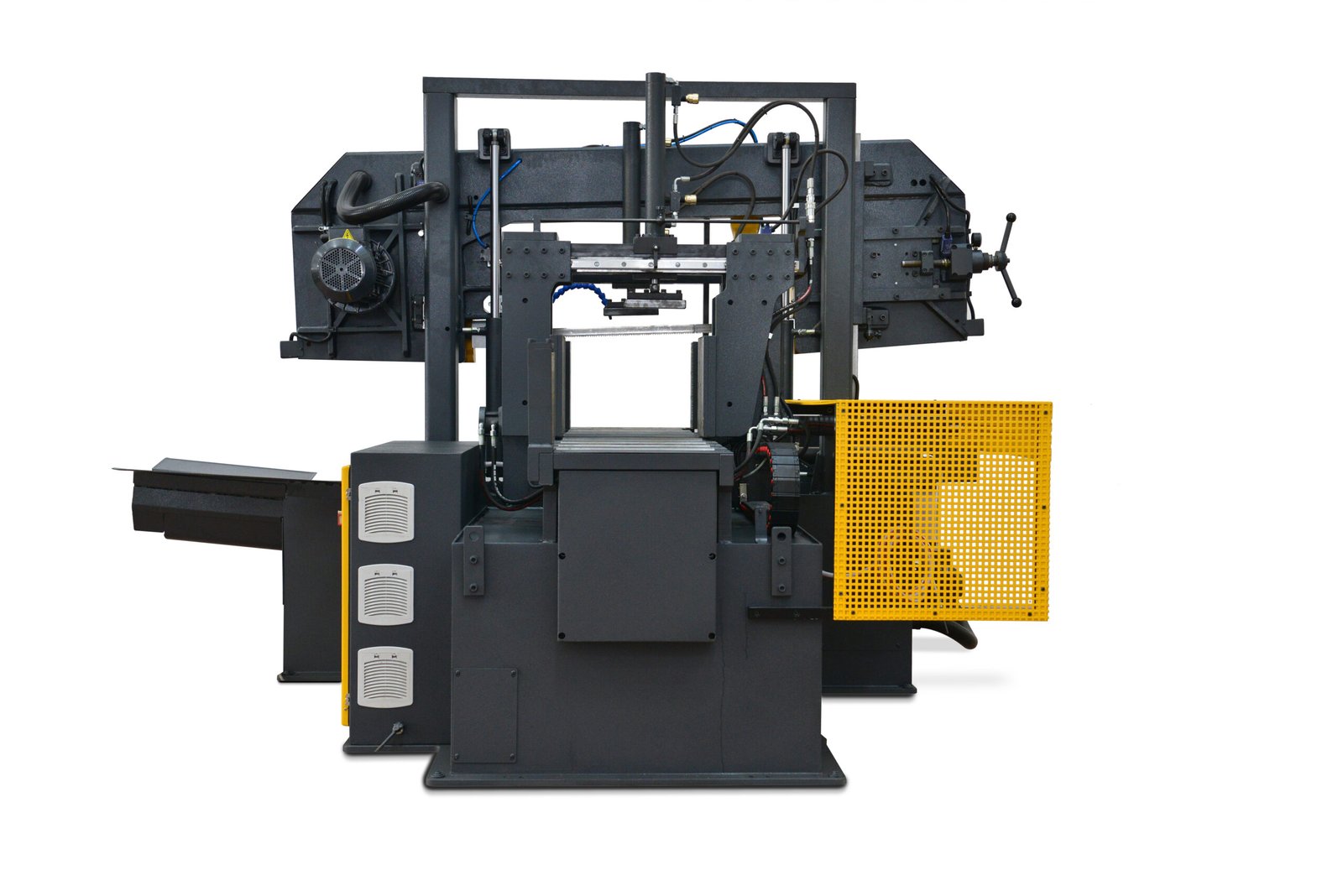

The Fully Automatic Drive Machine Twin Pillar Saw BMSO-360CS NC is engineered to handle demanding cutting tasks involving thick-walled profiles and solid materials. With a robust mono block saw frame and hydraulic vertical motion supported by linear guides, the Fully Automatic Drive Machine Twin Pillar Saw BMSO-360CS NC delivers stable and precise cuts, even in continuous high-volume operations. This horizontal band saw offers a feeding stroke of 19 11/16″ (500mm), allowing length input in a train. The machine utilizes an Omron programmable logic controller (PLC), offering users the ability to store up to 30 different cutting programs, streamlining the process for repeat jobs and minimizing downtime during setup.

A continuously adjustable cutting belt operates with precision at speeds ranging from 65′ 7 3/8″ (20m) to 328′ 1″ (100m) per minute. The design of the Fully Automatic Drive Machine Twin Pillar Saw BMSO-360CS NC incorporates linear guides that minimize vibration and ensure smooth movement during the cutting process. Chip conveyors and a planetary gearbox are included as standard features, contributing to overall durability and reduced maintenance. The machine was designed to meet the needs of small and mid-scale metal processing facilities, offering industrial-grade capabilities in a user-friendly format.

The Fully Automatic Drive Machine Twin Pillar Saw BMSO-360CS NC stands out as a reliable, efficient choice for fabrication shops seeking performance, consistency, and advanced automation. Whether cutting pipe, profile, or solid stock, this machine offers powerful results in a compact yet heavy-duty format.

Click here to see all drive machines.