Description

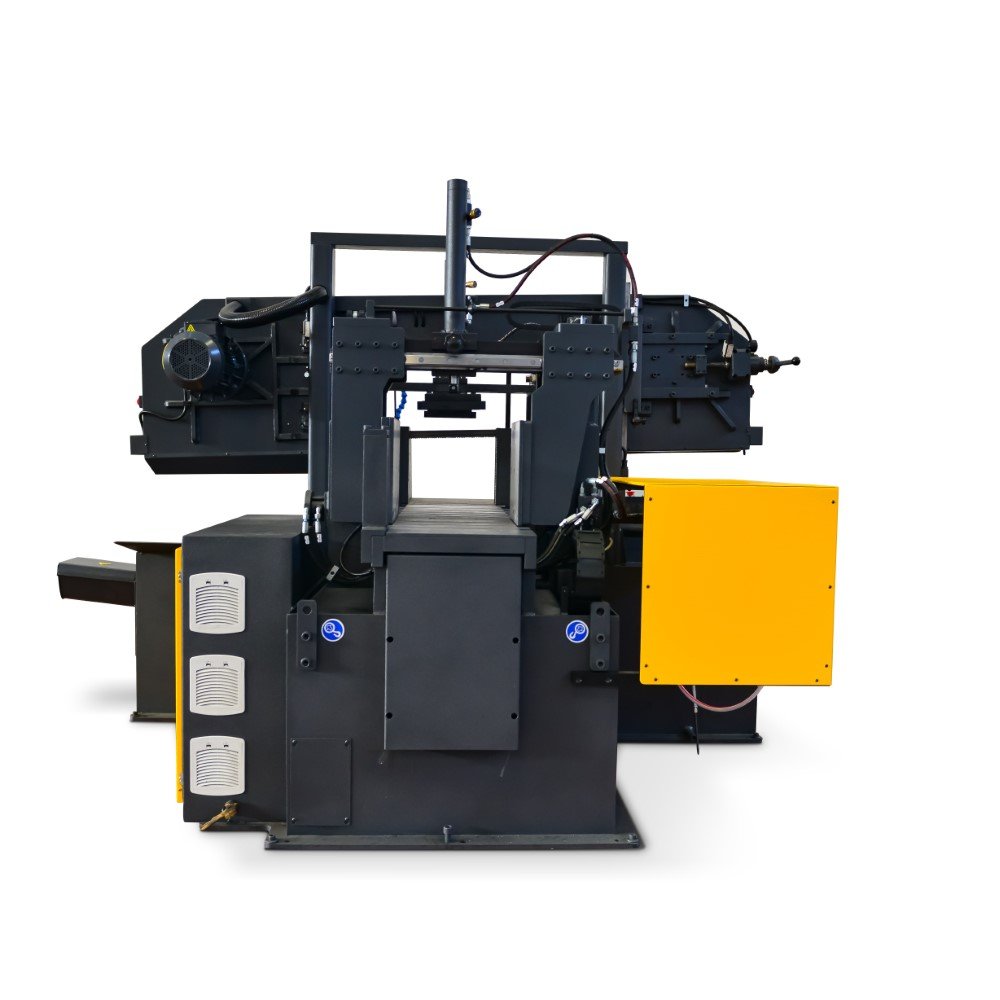

The Fully Automatic Drive Machine Twin Pillar Saw BMSO-330CS NC is engineered for sawing thick-walled profiles and solid materials with high precision and efficiency. The robust mono block saw frame features hydraulic vertical motion combined with a linear guide to ensure smooth and accurate cutting operations. This band saw is capable of feeding material up to 19 11/16″ (500mm) in length per train, allowing for consistent processing of large workpieces.

Cutting length and average feed numbers can be programmed via the Omron PLC, which supports up to 30 different cutting programs, providing great flexibility for varied production needs. The cutting belt speed is continuously adjustable, with precision ranging from 65′ 7 3/8″ (20m) up to 328′ 1″ (100m) per minute, ensuring optimal speed control for different materials and thicknesses.

Designed specifically for small metal processing operations, the machine includes numerous standard and advanced features to improve productivity and longevity. Key features such as a linear way guide minimize vibration during operation, while a chip conveyor helps maintain a clean workspace. Additionally, the planetary gearbox ensures efficient power transmission and durability under heavy use. This combination of features makes the Fully Automatic Drive Machine Twin Pillar Saw BMSO-330CS NC a reliable choice for demanding metal cutting tasks.

Click here to see all drive machines.