Description

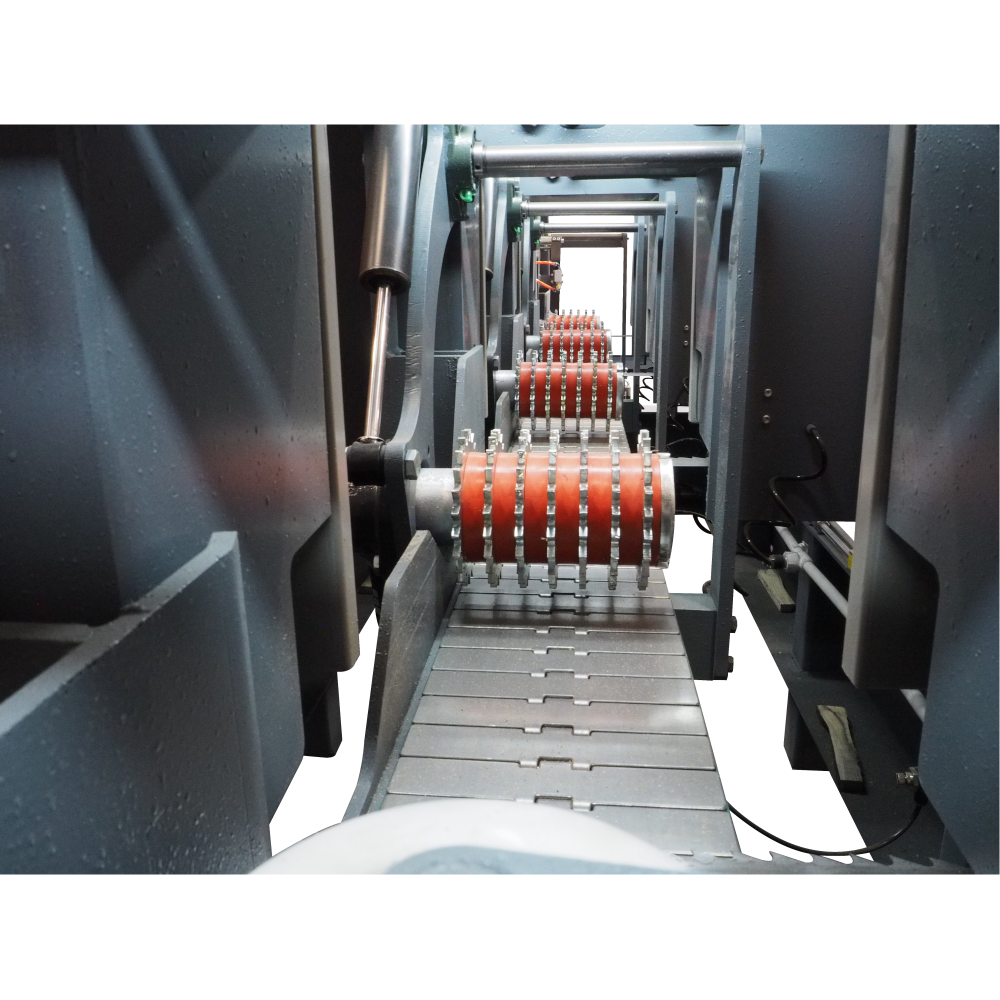

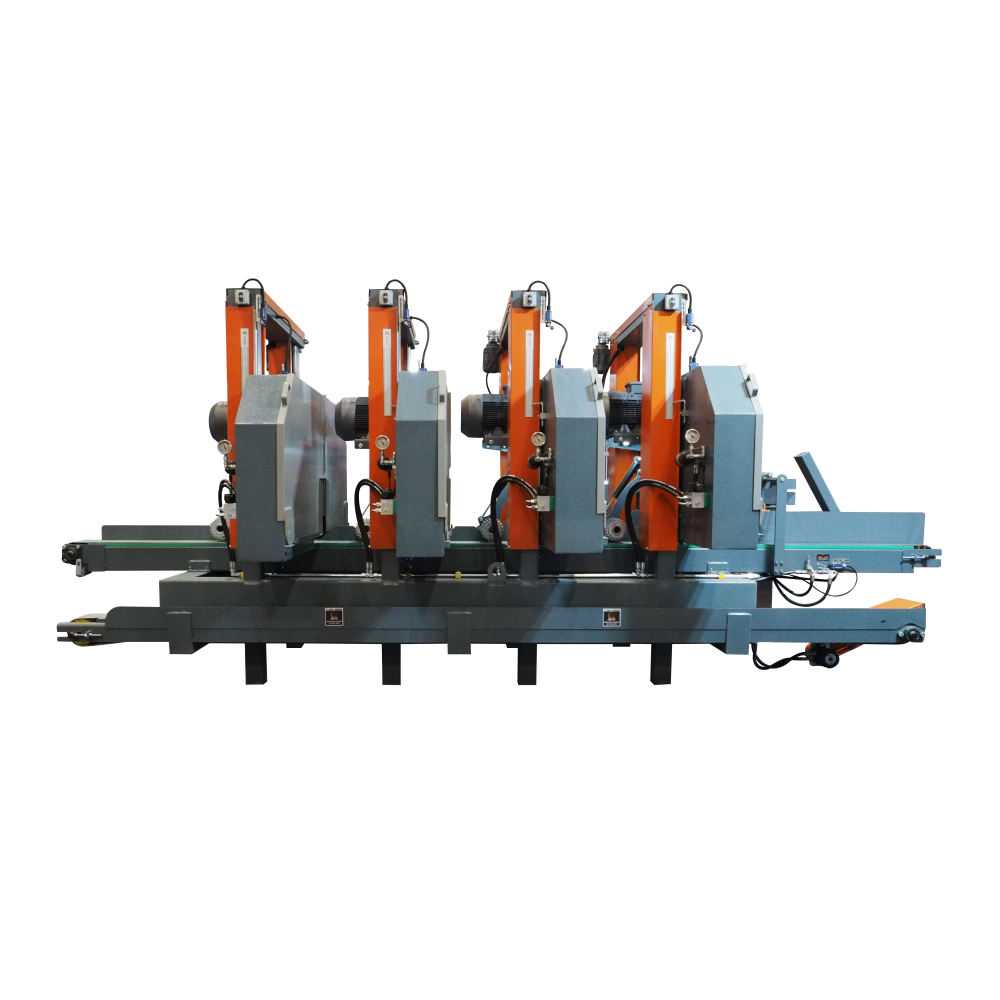

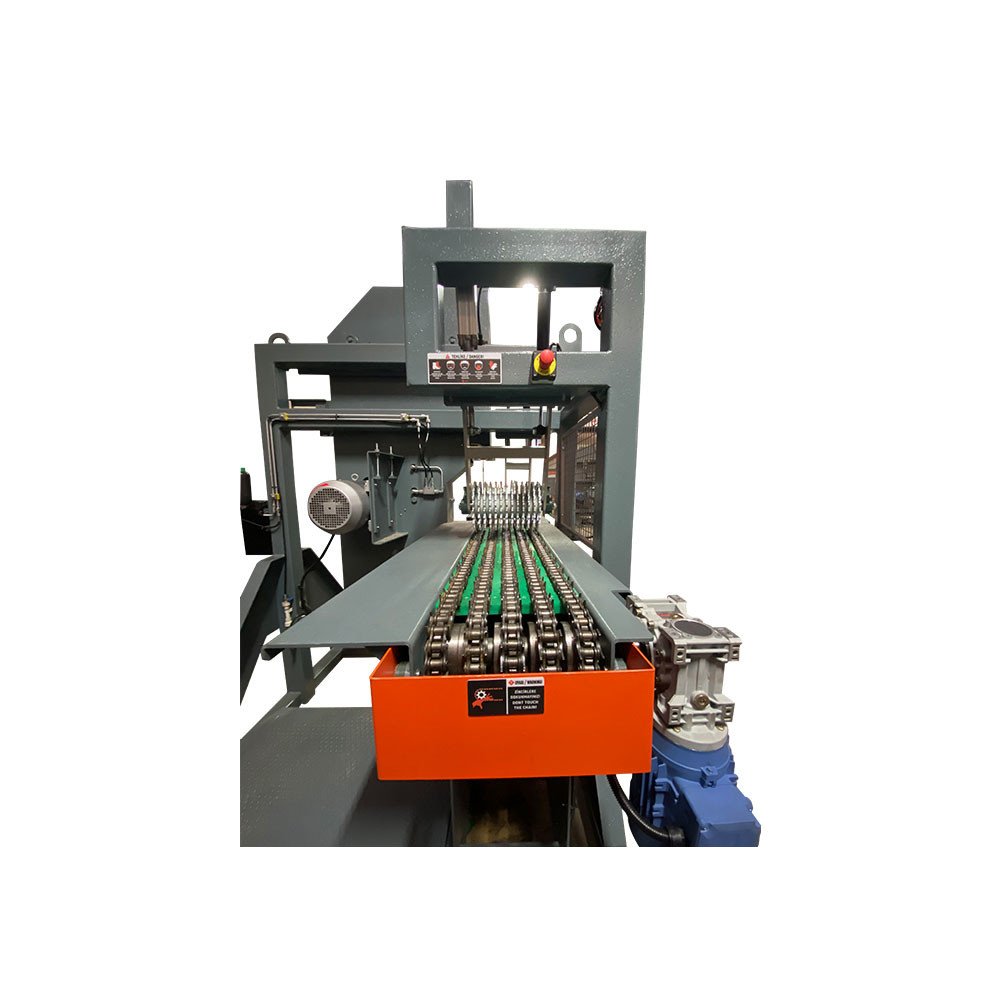

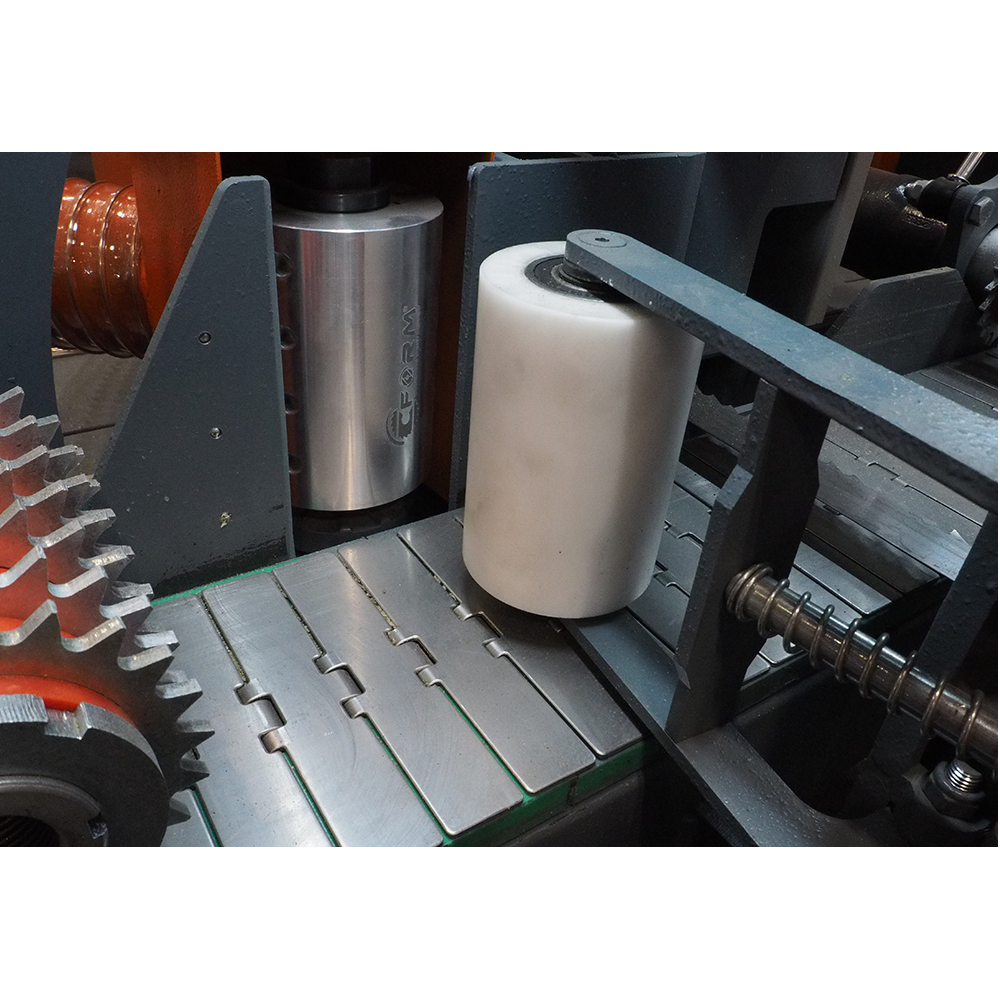

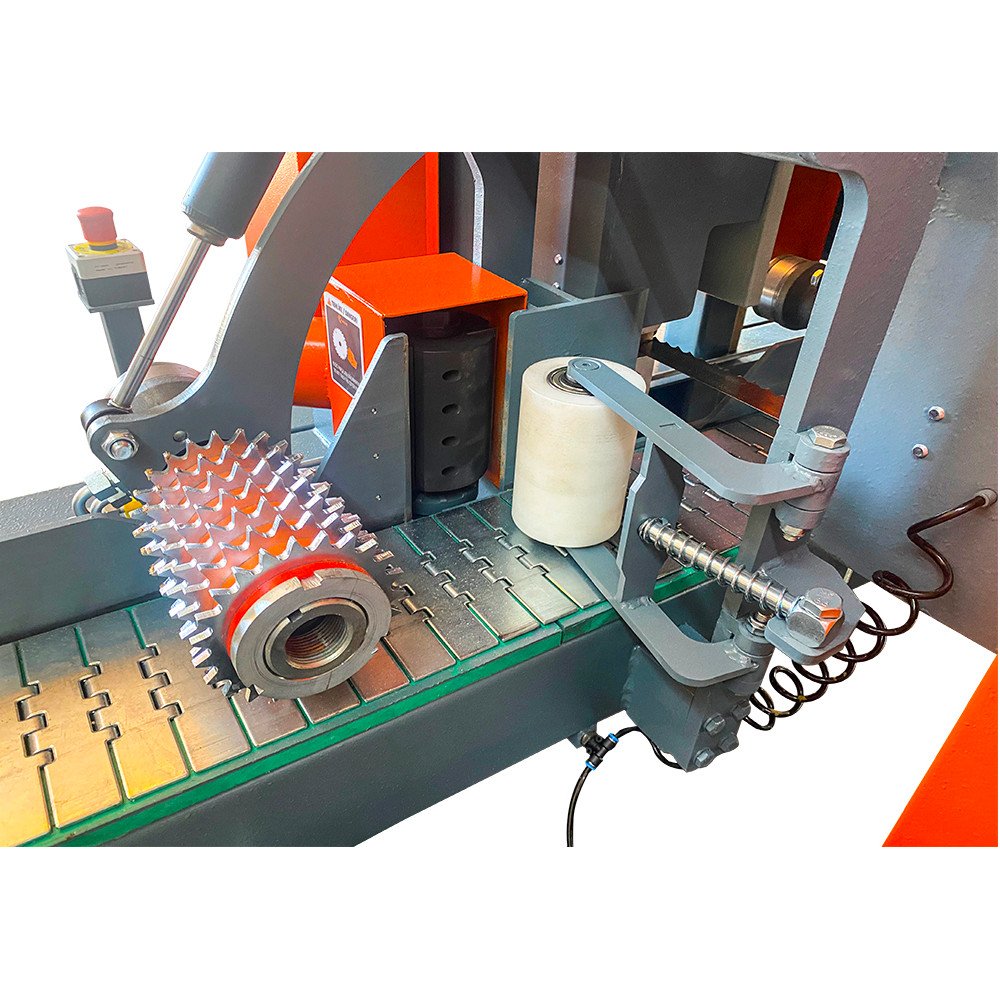

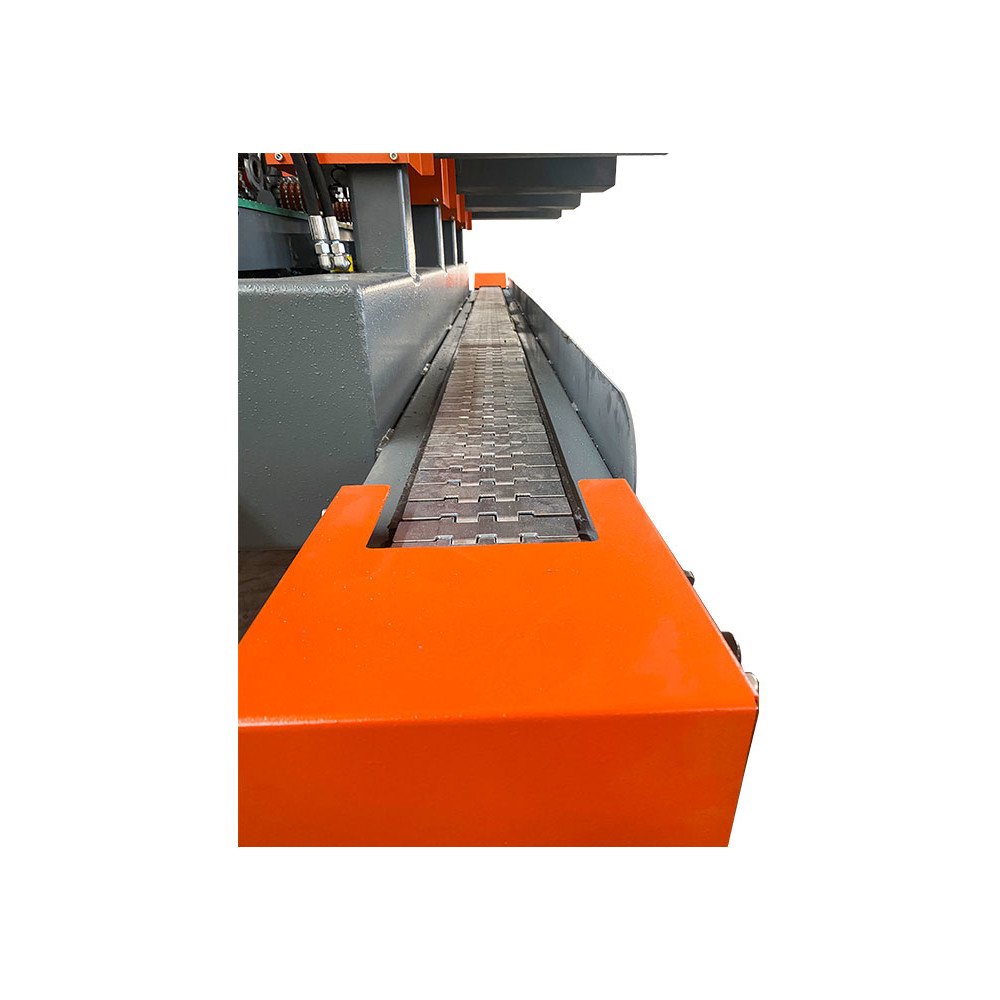

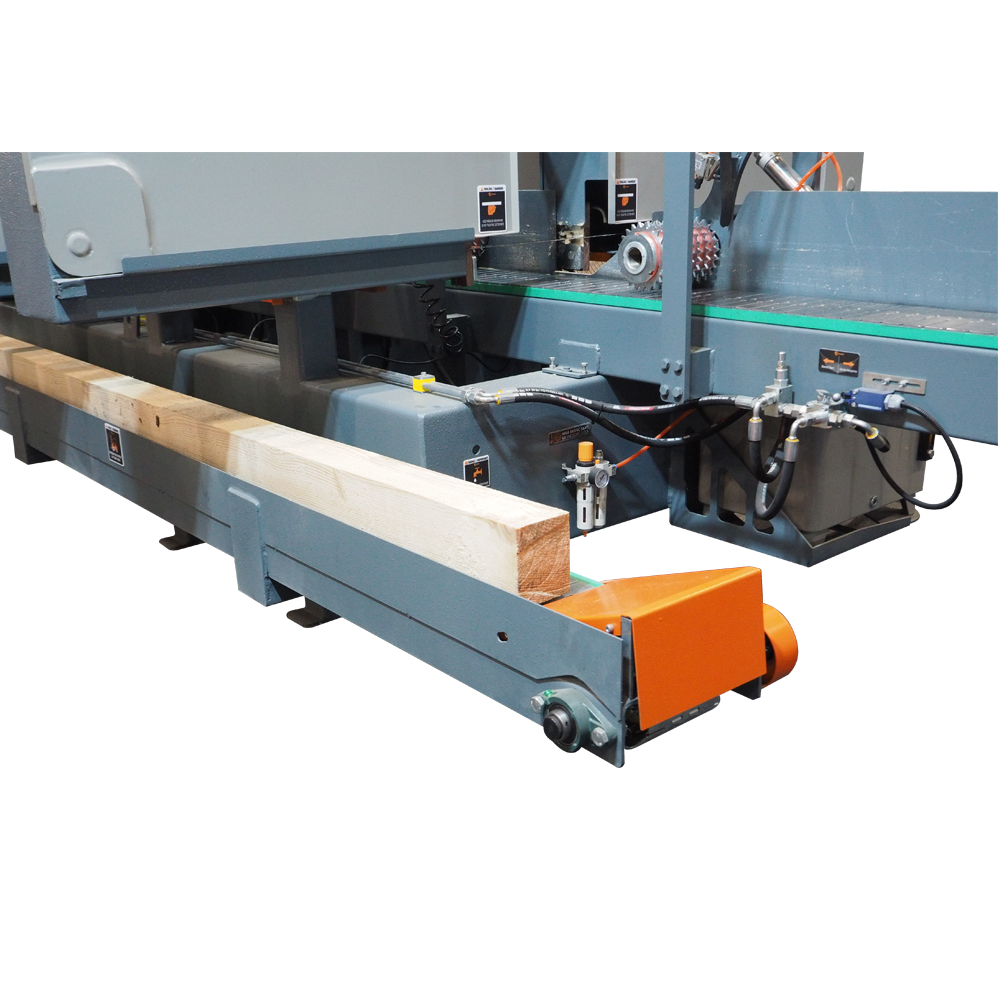

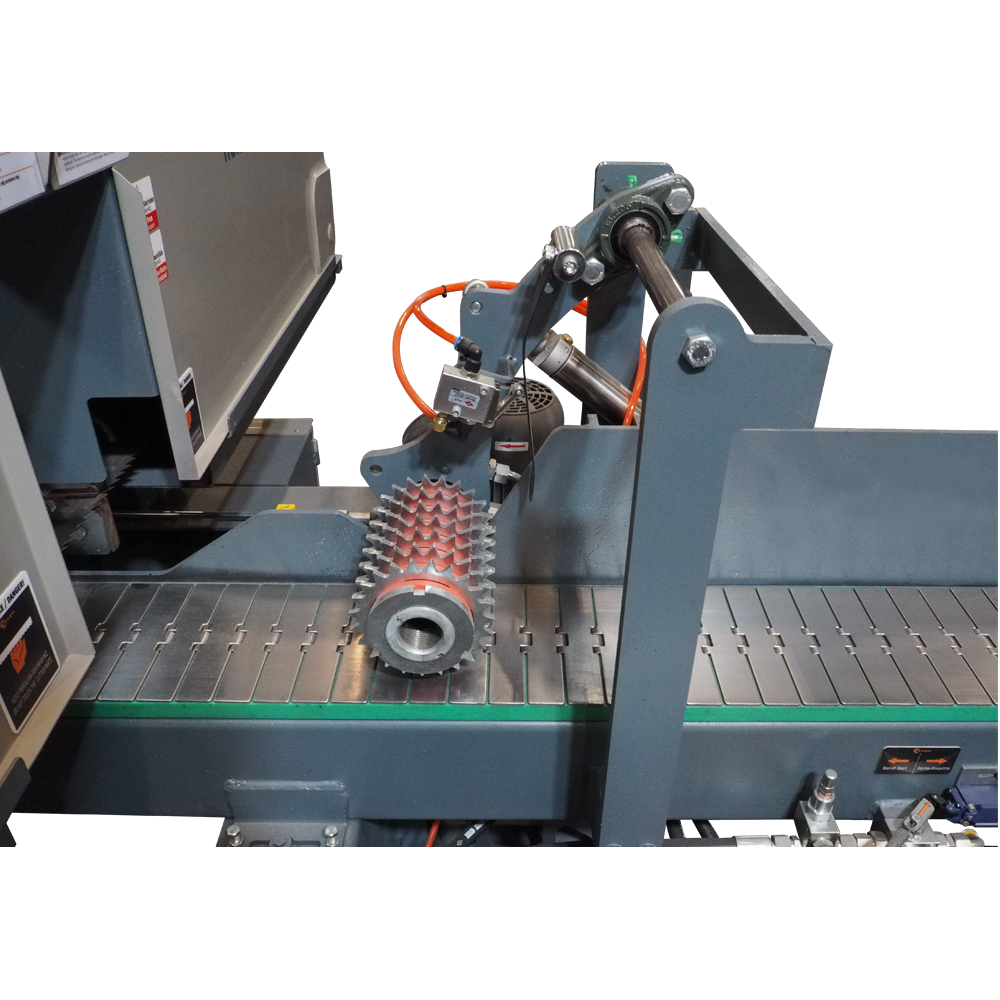

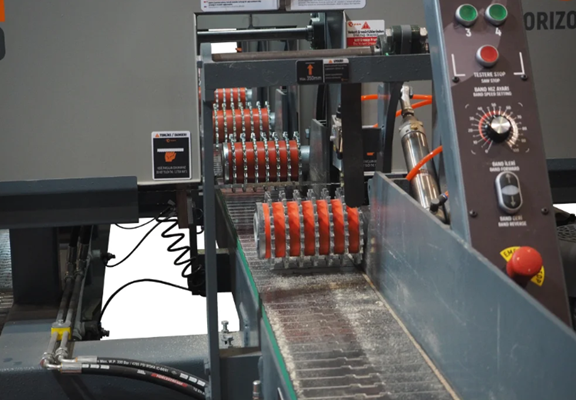

The Multihead Horizontal Resaw Machine is a high-capacity, heavy-duty modular resaw built for industrial-scale operations. Featuring a twin-track steel belt conveyor and up to four cutting heads as standard, it is capable of sawing up to six boards in a single pass. Designed for performance and efficiency, it uses thin-kerf blades to maximize yield and minimize waste with precise, clean cuts. A dust collector port ensures a cleaner work area, while the integrated water coolant system helps maintain blade integrity during long runs.

Blade tension is easily managed via the hydraulic system, and the saw’s height can be adjusted effortlessly using a hydraulic joystick. These features combine to accelerate your production speed and improve consistency. A separate control stand consolidates all machine functions into a single, user-friendly interface.

In its maximum six-head configuration, the Multihead Horizontal Resaw Machine can cut large sections into six boards and one slab in just one pass. Processed material can be returned to the operator using the reverse-direction steel belt conveyor. Its solid, powered body enhances stability and allows easier handling of short or tensioned cants.

The Multihead Horizontal Resaw Machine is expandable–add more heads to meet the growing output demands. With this capability, the Multihead Horizontal Resaw Machine delivers productivity and flexibility.

Click here to see all resaws.