Description

Unlock Maximum Efficiency with the Ultimate “2+3” Automated Manufacturing Cell

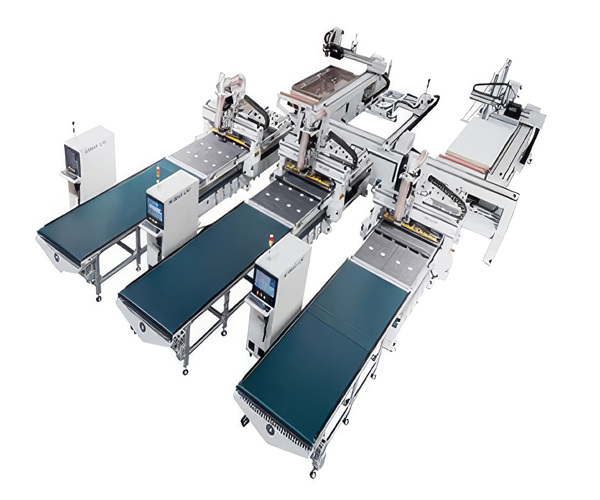

The Double Labeling & Triple CNC Nesting Production Line Yanagiba represents the pinnacle of automated panel furniture manufacturing. Designed for high-volume factories requiring speed, precision, and minimal labor, this intelligent production cell integrates two automatic labeling stations with three independent CNC nesting routers.

By synchronizing Double Labeling capabilities with Triple CNC Nesting power, the Yanagiba model eliminates bottlenecks, allowing a single operator to manage a workflow that would traditionally require multiple teams. Whether you are producing custom cabinetry, wardrobe systems, or office furniture, this production line delivers the “cutting-edge” precision implied by its name.

## Key Features & Innovations

-

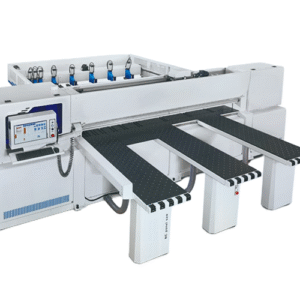

High-Speed “2-Drag-3” Configuration: The system features two automatic labeling machines at the front end that seamlessly feed into three high-performance CNC nesting machines. This unique ratio ensures that the cutting stations are never waiting for materials, maximizing spindle uptime.

-

Fully Automated Workflow: From auto-loading and barcode labeling to nesting, drilling, and cutting, the entire process is automated. The plates remain in a suspended state during distribution to prevent surface scratches.

-

Massive Production Capacity: Capable of processing 300–360 sheets per 8-hour shift, this line outperforms three separate single-unit machines while occupying significantly less floor space.

-

Intelligent Central Control: Powered by a Syntec industrial control system, the line automatically distributes cutting plans to the available nesting stations, optimizing material usage and workflow balance.

-

Labor & Space Saving: This integrated solution replaces the need for multiple operators and redundant conveyor systems. A single operator can oversee the entire Double Labeling & Triple CNC Nesting Production Line, reducing labor costs and human error.

## Technical Specifications

| Feature | Specification |

| Model Name | Yanagiba Series (Double Label & Triple Nesting) |

| Configuration | 2 Automatic Labeling Stations + 3 CNC Nesting Routers |

| Daily Output | 300 – 360 Sheets / 8 Hours |

| Control System | Taiwan Syntec Industrial Controller |

| Driving System | High-Torque Servo Motors (Yaskawa/Eston) |

| Spindle Power | 9KW / 12KW Air Cooling ATC Spindle |

| Max Travel Speed | 80m/min |

| Cutting Speed | 25m/min |

| Table Structure | Vacuum Adsorption Table with Zoning |

| Workpiece Protection | Suspended plate transport (Anti-scratch technology) |

## Applications

The Double Labeling & Triple CNC Nesting Production Line is engineered for:

-

Panel Furniture: Whole-house custom furniture, wardrobes, and cabinets.

-

Kitchen Cabinetry: High-volume carcass and door production.

-

Office Furniture: Mass production of desks and storage units.

-

Wooden Doors: Precision cutting and modeling for interior doors.

## Why Choose the Yanagiba Production Line?

In the competitive world of furniture manufacturing, speed and data tracking are critical. The Double Labeling & Triple CNC Nesting Production Line ensures that every panel is accurately tracked from the moment it enters the cell. The dual-labeling entry point removes the common bottleneck of manual sticker application, while the triple-nesting array ensures your factory output meets the highest demands of the market.

Experience the future of smart manufacturing with the precision of Yanagiba.