Description

Revolutionize your joinery production with the ultimate fusion of precision drilling, multi-axis milling, and traditional craftsmanship automation.

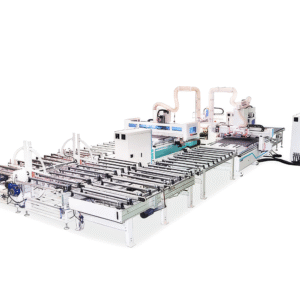

The Intelligent Woodworking Drilling and Milling Machining Center Multi-Dimensional Connection Swallow is a state-of-the-art CNC solution designed for high-end furniture manufacturing. Engineered by Xpro, this machine bridges the gap between modern mass production and the durability of traditional wood joinery. It is specifically optimized for creating complex, multi-dimensional connections—including the prestigious swallowtail (dovetail) tenon—with fully automated precision.

Product Overview

In the competitive landscape of solid wood and panel furniture production, efficiency and joint quality are paramount. This machine moves beyond standard vertical drilling to offer a comprehensive machining center experience. By integrating intelligent control systems with multi-axis flexibility, it allows manufacturers to execute intricate drilling and milling operations on multiple faces of a workpiece in a single clamping.

The core innovation lies in its “Swallow” connection capability. This feature automates the milling of swallowtail tenons and mortises—a hallmark of high-quality craftsmanship—eliminating manual errors and drastically reducing production time.

Key Features & Benefits

1. Intelligent Multi-Dimensional Connection

Unlock the power of true 3D machining. The Intelligent Woodworking Drilling and Milling Machining Center Multi-Dimensional Connection system utilizes advanced axis control to process workpieces from multiple angles. Whether you are creating angled tenons, complex locking joints, or standard dowel holes, the machine ensures perfect alignment and fit on all dimensions.

2. Specialized Swallowtail (Dovetail) Milling

The “Swallow” designation refers to the machine’s specialized proficiency in creating swallowtail joints.

-

Seamless Joinery: Automatically mill male and female dovetail components with micron-level precision.

-

High Structural Integrity: Produce furniture with superior mechanical strength without the need for screws or nails.

-

Aesthetic Value: Deliver the premium look of hand-cut joinery at industrial speeds.

3. High-Precision Drilling & Milling Units

Equipped with high-speed spindles and a robust drilling bank, this center handles heavy-duty tasks with ease.

-

Versatile Tooling: Switch seamlessly between drilling bits for assembly holes and milling cutters for grooving or shaping.

-

Clean Edges: High RPM capabilities ensure tear-free cuts on solid wood, MDF, and particleboard.

4. Smart Manufacturing Integration

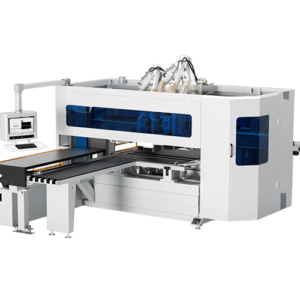

Step into Industry 4.0. The machine features an intelligent PC-based control system that integrates easily with major cabinet design and CAM software.

-

Barcode Scanning: Scan and process for reduced setup time.

-

Visual Interface: Real-time monitoring of machining paths.

-

Error Prevention: Intelligent sensors detect workpiece positioning to prevent machining errors.

5. Heavy-Duty Construction

Built on a industrial-grade chassis, the machine minimizes vibration during high-speed operation, ensuring that the Intelligent Woodworking Drilling and Milling Machining Center Multi-Dimensional Connection maintains accuracy over years of continuous use.

Technical Specifications (Highlight)

-

Machine Type: CNC Drilling & Milling Center

-

Primary Application: Solid Wood Joinery, Panel Furniture, Swallowtail/Dovetail Connections

-

Control System: PC-based Intelligent CNC

-

Processing Modes: Multi-sided drilling, Slot milling, Tenon making

-

Compatible Materials: Solid Wood, Plywood, MDF, Chipboard

Why Choose This Machine?

If your production line requires the flexibility to switch between standard cabinet carcass processing and high-value solid wood joinery, the Intelligent Woodworking Drilling and Milling Machining Center Multi-Dimensional Connection Swallow is your ideal solution. It removes the bottleneck of complex joint creation, allowing you to scale production without sacrificing quality.