Description

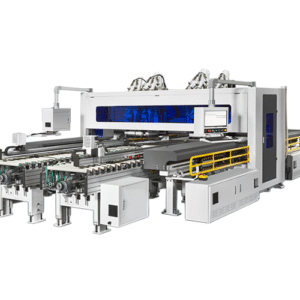

Elevate your furniture production line with the CNC Drilling Machine Florence, a state-of-the-art solution designed for the modern woodworking industry. Modeled after the high-performance DA-6125LT architecture, the Florence edition redefines speed and accuracy. Whether you are manufacturing custom cabinetry, office furniture, or modular wardrobes, this CNC Drilling Machine offers the automation required to scale your business.

Product Overview

The CNC Drilling Machine Florence is engineered to handle complex boring and milling tasks with exceptional ease. As a through-feed drilling center, it eliminates the bottlenecks associated with manual setup. By integrating advanced control software with robust mechanical components, the Florence ensures that every panel is processed with micrometer-level precision. This machine is not just a tool; it is a complete production partner capable of handling six-sided drilling and top/bottom grooving in a single pass.

Key Features

-

Intelligent Process Automation: The Florence is designed to seamlessly integrate with your existing furniture design software. By scanning a barcode, the CNC Drilling Machine automatically loads the processing file, adjusting the clamps and drill heads without manual intervention.

-

High-Speed Multi-Sided Operation: Time is money in manufacturing. The Florence edition features dual drilling banks (top and bottom) capable of processing all six sides of a panel simultaneously. This significantly reduces cycle times compared to traditional single-head machines.

-

Precision Milling Capabilities: Beyond standard holes, this CNC Drilling Machine excels at routing and grooving. It is perfect for creating invisible connections (Lamello slots), back panel grooves, and complex hinge cuts.

-

Air-Floating Table Design: To protect delicate surfaces, the Florence utilizes an air-floating worktable. This ensures that high-gloss, laminated, or veneered panels glide through the machine without scratching or surface damage.

-

User-Friendly Interface: The machine is equipped with an intuitive HMI (Human-Machine Interface) that allows operators to monitor production status, manage files, and troubleshoot in real-time.

Why Choose the Florence CNC Drilling Machine?

In the competitive landscape of panel furniture manufacturing, reliance on manual drilling is no longer viable. The CNC Drilling Machine Florence offers a return on investment through reduced labor costs and minimized material waste.

Unlike standard vertical drills, the Florence (DA-6125LT) provides a continuous workflow. Its “scan-and-go” technology allows operators with minimal training to produce expert-level results. The heavy-duty frame absorbs vibration, ensuring that the drill bits remain stable even during high-speed operation, resulting in clean, chip-free holes every time.

Technical Excellence

The CNC Drilling Machine is built with premium components, including high-precision linear guides and servo motors that ensure long-term reliability. The “LT” configuration emphasizes a streamlined loading and unloading process, optimizing the flow of materials through your factory floor.

Ideal Applications:

-

Custom Kitchen Cabinetry

-

Modular Wardrobes and Closets

-

Office Furniture Systems

-

Flat-Pack Furniture Production

Upgrade your workshop today with the CNC Drilling Machine Florence—where Italian-inspired design meeting industrial-grade performance.

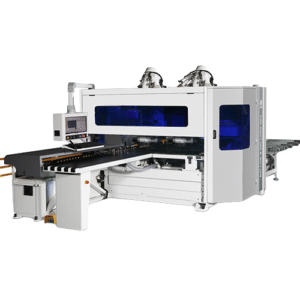

Multifunctional drill bag

Mobile air cushion table

Double spindle