Description

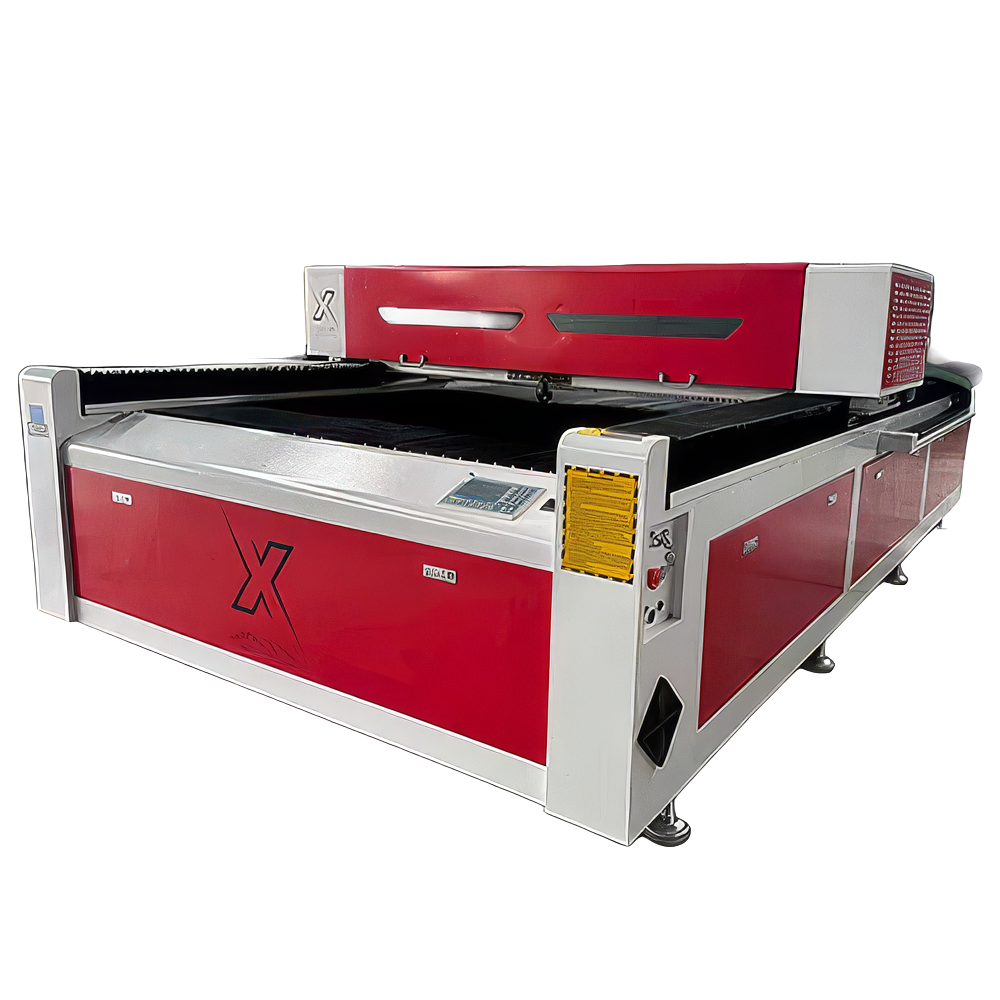

Low-cost laser cutter for cardboard, mdf, paper, acrylic, fabric, leather, and foam.

Prices from CAD $4,200.00

Leo CO2 laser available from 30w – 180w laser power. Control system allows engraving on different layers to make both operations available in one simple step. integrated co2 cutter solution system for laser honeycomb table loading, sorting, cutting and easy,

Honeycomb tables provide a stable foundation for the small parts that are sure not only stable cutting operation but also easy to unload. All small pieces can be picked up from the table once the cutting process is completed. Price of the co2 cutting process makes the purchase decision easty. cutting. Leo is your all in one solution for laser automation. Xpro cnc proud to represent automation systems to increase the intelligent abilities for sheet metal processing automation for fiber laser cutters.

No consumable gas required for cardboard cutting

Wood, acrylic, paper, fabric, foam, plastic, rubber, glass materials cutting and engraving

Cutting speed can be arrange for different material starting from 10mm per second to 450mm per second.

Cuts 22mm acrylic on low power

Available from 20w to 500w CO2 laser source

Our values drive everything we do

Why choose an Xpro CO2 Laser?

A CO2 laser cutter is a profitable investment when you can rely on both its quality and cutting speed. With local sales and service support, our CO2 laser stands out among suppliers, offering dependable performance and long-term value.

20W – 500W CO2 laser power selection:

Low power (20W-120W): suitable for engraving, marking, and cutting thinner material like wood, acrylic, and cardboard,

Medium Power (150W – 500W): It offers greater versatility, allowing both engraving and cutting on a wide range of materials, including thicker options.

High Power: Not recommended for non-metal cutting applications, as operating costs increase significantly.

Xpro’s industrial engraving laser system with an integrated cutting table increases production capacity by up to 30%, helping reduce the cost per piece. The CO2 laser cutting table can be positioned in different orientations at the factory, while the open-table design makes loading large sheets of non-metal material quick and easy.

Leo engraver and cutter equipment represent the new standard in automation for 2025, designed to deliver faster cutting speeds and improved efficiency in the CO2 laser market.

During customer testing, the system successfully cut through three layers of cardboard in a single pass at a speed of 60mm per second.

The Xpro Leo high-performance exchange table laser cutting machine is built to handle a wide variety of materials with speed and accuracy. The intelligent system automatically detects the selected metal type and thickness, then selects and changes the predefined nozzle for optimal cutting results.

The automatic combination fiber laser cutter control system manages different metal thicknesses with ease. The open table platform simplifies cutting and unloading, while plates can be loaded from the left, right, or bottom using a forklift, crane, or jib crane for maximum flexibility.