Description

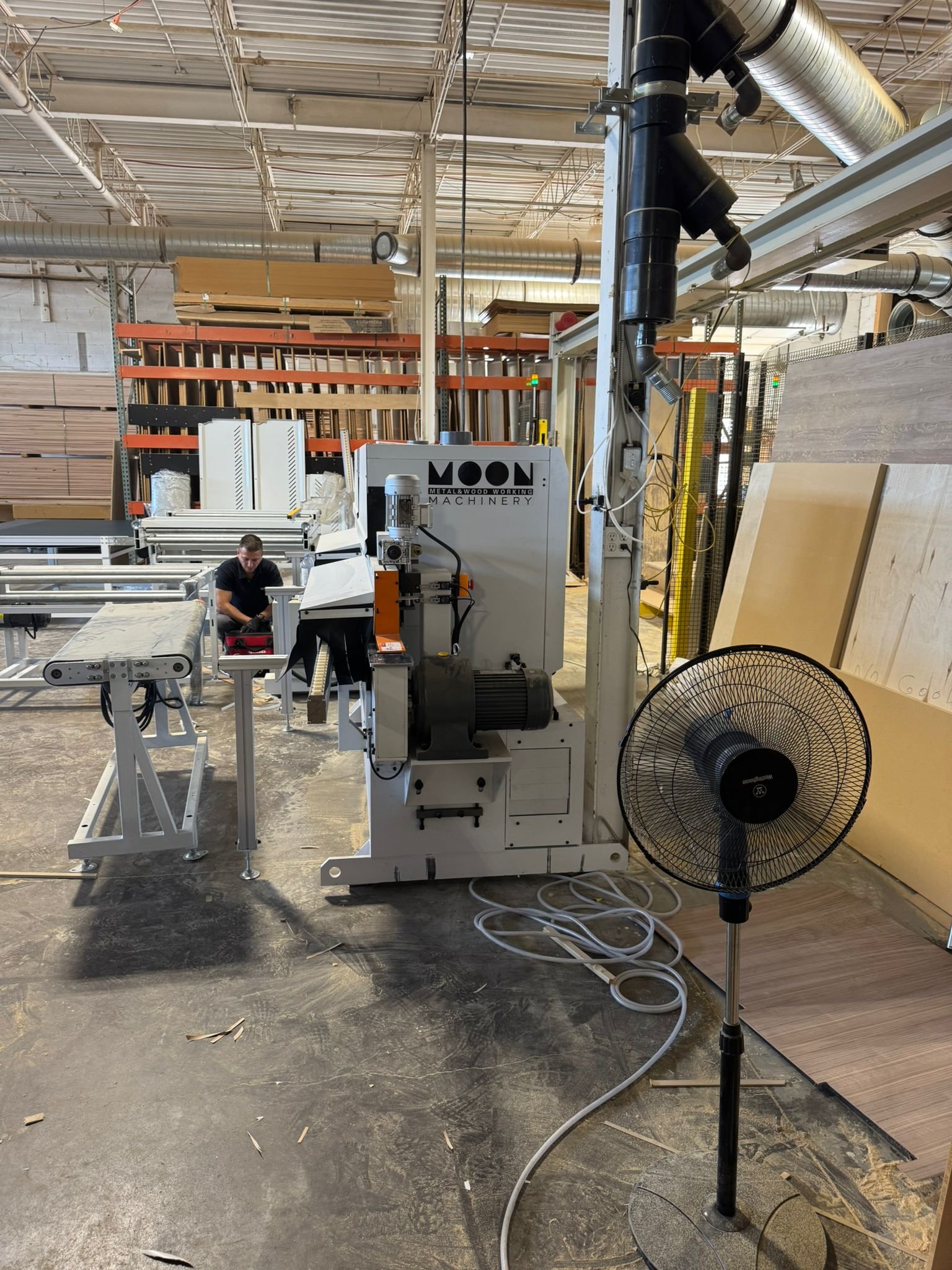

The UV Edge Coating Machine is a roller edge coating system engineered with a customized, solid structural design capable of feeding doors up to 20 feet long for precise edge coating applications. Built for durability and adaptability, the unit comes standard with a sanding station, UV rollers, and UV drying unit, while optional upgrades such as trimming tools, radius blades, and additional sanding units (oscillation or belt) allow the machine to be tailored to specific production requirements.

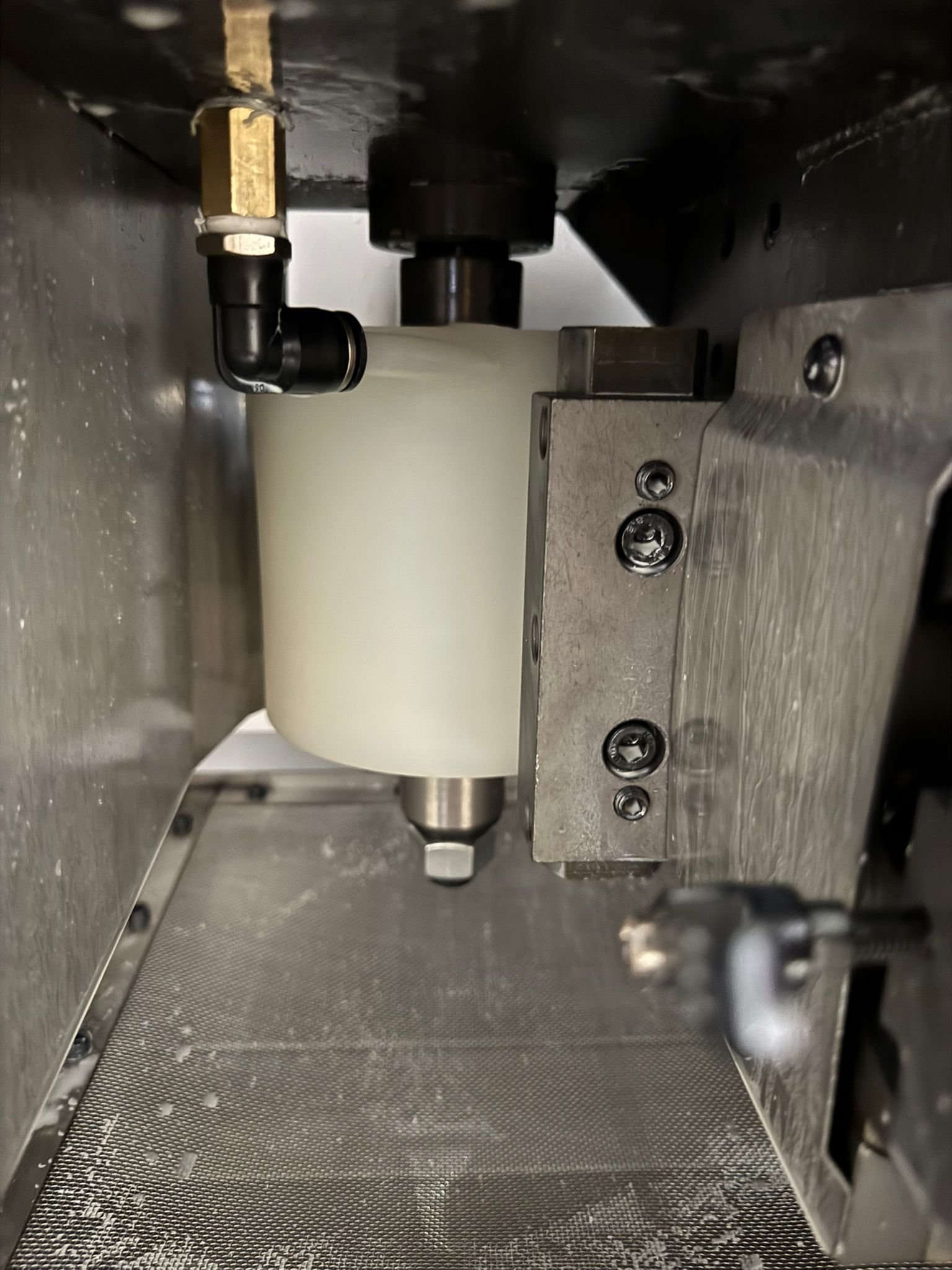

Versatile in application, the UV Edge Coating Machine can process solid wood, composite materials, MDF panels, doors, and drawer components with efficiency and consistency. Once UV paint is applied with the roller to the edges of the wood board, UV lamps cure the coating instantly, producing smooth, ready-to-install edges. Operators can configure the system with either GA or mercury lamps, a critical factor that depends on the type of UV paint being used and the required drying time.

To ensure optimal performance, each sale of the UV Edge Coating Machine includes expert consultation. Customers are encouraged to provide sample material thickness and length details, along with time studies of part processing, so that the machine can be fine-tuned to meet exact production needs.

Engineered for precision, flexibility, and durability, the UV Edge Coating Machine is a reliable solution for manufacturers seeking superior edge coating quality and efficiency.