Description

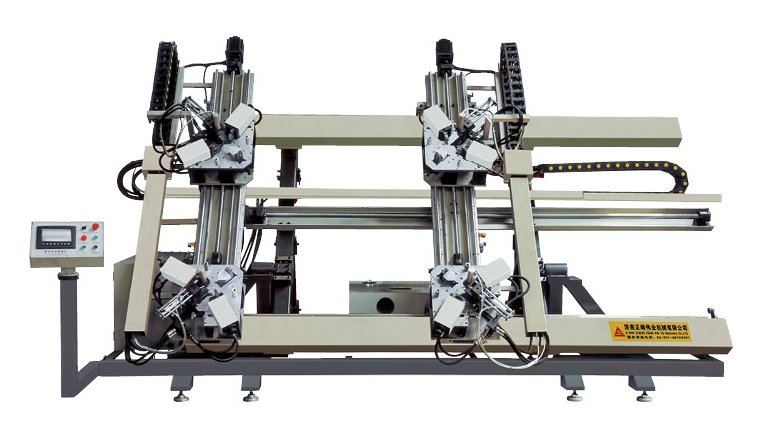

The 4 Head Corner Crimping Machine is an advanced solution designed for the efficient assembly of colour aluminum doors and windows as well as insulated aluminum frames. Built to handle 45-degree angle sets, it allows four corners to be crimped at once, enabling the complete assembly of a window frame or sash in a single operation. This not only improves production efficiency but also ensures consistent precision, making it an indispensable tool for manufacturers working with aluminum window and door systems.

With its main fuel tank located below the table, the 4 Head Corner Crimping Machine offers easy loading and unloading for improved operator convenience. The design is particularly suited for insulated aluminum windows, with an adjustable stroke that accommodates a wide range of profiles. An independent mobile console further enhances flexibility, allowing operators to manage the machine with ease, while the reinforced compression guide bar prevents dislocation of profiles during crimping, ensuring clean and accurate assembly results.

In terms of specifications, the 4 Head Corner Crimping Machine operates with a 380V/50Hz power supply and has a rated power of 7.5kW. It delivers a rated oil pressure of 15 MPa and requires air pressure of 0.5-0.8 MPa. The oil tank has a capacity of 60 L, and the corner-combining cylinder stroke ranges from 0 to 60 mm. The machine supports an assembly maximum frame size of 1800×3000 mm and a minimum frame size of 450×450 mm. Its overall dimensions are 4700x2000x2600 mm, offering a robust yet practical footprint for production facilities.

By combining precision, efficiency, and durability, the 4 Head Corner Crimping Machine delivers a complete solution for fabricators aiming to streamline window and door assembly processes.