Description

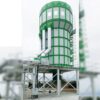

The Industrial Dust Collector Silo features a mechanical vibration system and comes standard with an automatic discharge mechanism. It offers a more economical investment compared to traditional round silos. The unit an be emptied even while suction fans are running and sensors provide audible alerts when the chip storage reaches its limit.

The system not only collects dust but also stores it efficiently. The stored sawdust can either be discharged into a truck or used as fuel in solid fuel boilers. Dust and chips are transported to the discharge outlet via a worm screw conveyor, where a rotary valve manages the release. This flexible system allows for disposal based on operational needs.

Designed specifically for dry wood dust, the Industrial Dust Collector Silo can store up to 130 cubic meters, or 1,400 cubic feet, making it ideal for large-scale woodworking productions.

Do you have a Dust collection Problem?

If you’re looking for a reliable and cost-effective solution for managing large volumes of wood dust and chips, the Industrial Dust Collector Silo is the ideal choice. Engineered for efficiency, this dust collection system not only stores and filters dust but also provides seamless automatic discharge as a standard feature. Compared to traditional round silos, it offers significant savings in investment costs.

The Industrial Dust Collector Silo stands out with its ability to be emptied while suction fans are in operation–ensuring zero downtime. Built-in sensors audibly alert you when chip storage nears capacity, so your operation stays smooth and uninterrupted.

The Industrial Dust Collector Silo’s robust design includes a worm screw conveyor that transfers dust and chips to the discharge outlet, where a rotary value keeps the process clean and contained. Whether you’re offloading to a truck or fueling a solid fuel boiler, the discharge system is both practical and efficient.

To ensure consistent flow and prevent the formation of compressed layers, the Industrial Dust Collector Silo features an internal mixer that keeps the contents evenly distributed.

Structural Specifications of Silo

The Silos are manufactured modularly

All Silos are painted with electrostatic dye powder.

Service Area

All silos are serviced by qualified service technicians in North America

Capacity

There are three type of silos 35000 cubic meter hour or 20000 cfm 45000 cubic meter hour or 27000 cfm 75000 cubic meter hour or 45000 cfm.

Click here to see all dust silos.