Description

Introducing our Robotic Stretch Wrapping Machine

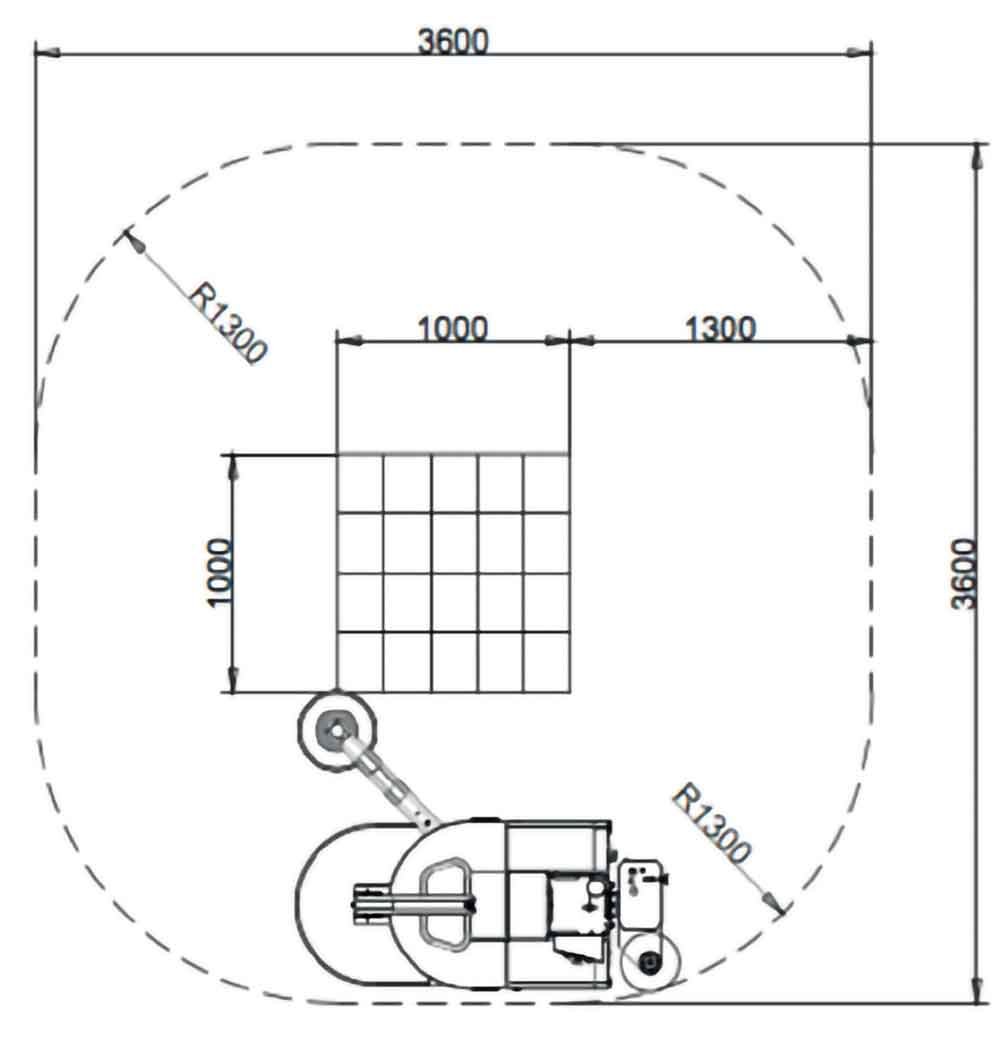

Are you tired of manual stretch wrapping that is time-consuming and labor-intensive? Look no further than the Robotic Stretch Wrapping Machine, also known as the Robo Wrap 600 B, a state-of-the-art, self-propelled stretch-film wrapping robot for palletized loads of various shapes and sizes. With features such as a digital color display, adjustable wrapping parameters, automatic film cutting, and a PLC controlled system, this Robotic Stretch Wrapping Machine will increase efficiency and save you both time and money.

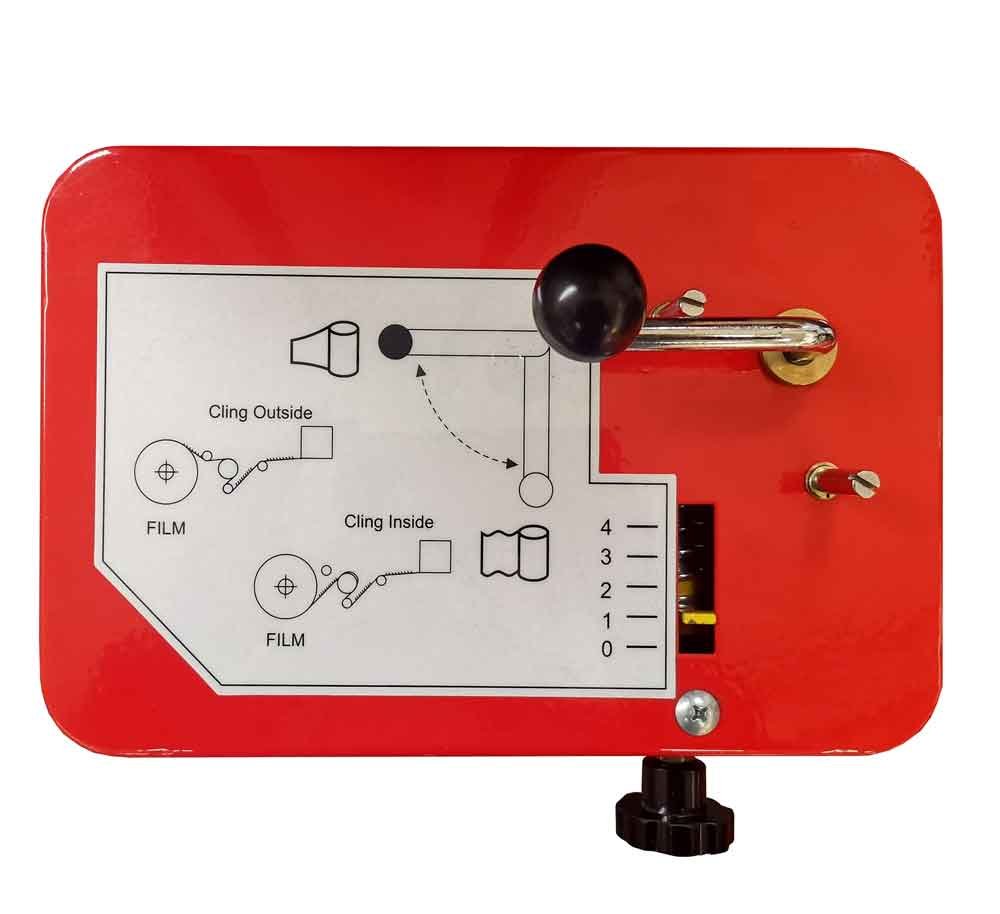

Additionally, it has battery operated AGV, high frequency battery charger, powered pre-stretch system, safety bumper, emergency stop, and cycle counter. With the Robo Wrap has two main models A and B,The main difference is that B model has two optional 230 – 300% pre stretching motor. You’ll be able to handle up to 150 pallets per charge and have a full charge cycle time of 8 hours. The Robo Wrap 600 B is also equipped with features for handling different type of rolls and stretch film.

Don’t miss out on this opportunity to revolutionize your wrapping process with the portatif robotic stretch filming robot.

Contact us today to purchase!

With the pre-stretching option you will be saving 50% of your stretch filming cost.

What is special of our Robotic Stretch Wrapping Machine

Film tention can be adjustable by means of mechanical or motorized. Easy to use digital touch screen allows to operator to create their own recipe. All robots comes with high qualoty 2 agv 12 volt battery which is expected to wrap one hundred and fifty pallets per shift.

PLC control system supplied by german well-known electronic supplier Siemens , model S7/200

Pallet stretching settings can be pre-define in the control screen to create different start and finish turn cycle of the pallets or any boxes. Stretch filming machine sale made easy with our online shopping tool.

We provide after sales , service and spare part for the all Stretch Film Machines we sell. All of our machine comes with standard one year factory warranty.

Click here to see product info and learn price of the machine your first wrapping robot not too far fetch machine.

Key Features

- Touch Screen control panel

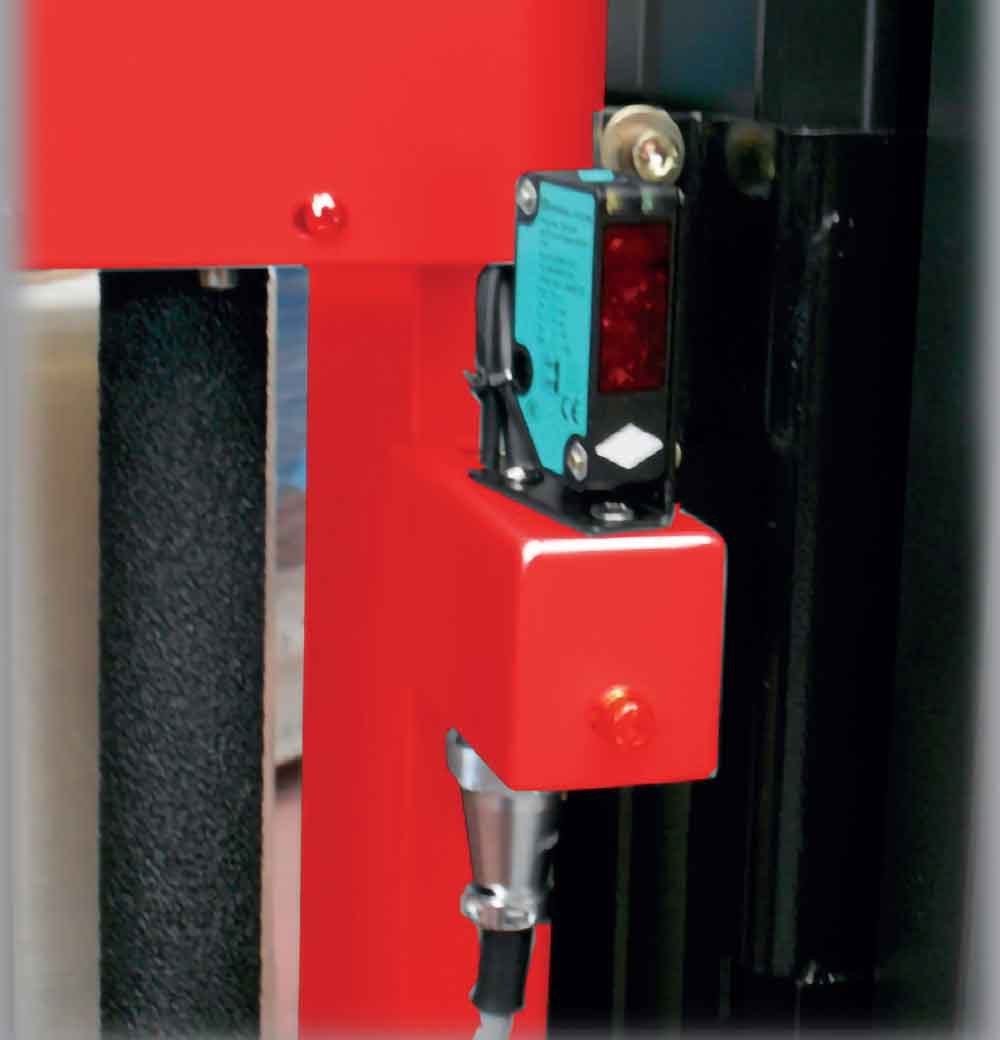

- Photocell Sensor

- Automatic film Cutting

- Easy to change stretch roll

- Pre-stretch system made it so easy for adjustments

- Mobile structure allows for forklift lifting

- Safety stop tools

Edge banding with fast edge thickness adjustment system, semi-auto height system and maximum efficient with PLC dispay controlled machine for medium scale production facilities. 601 N is a compact machine with two different speed compacted units which provides a professional solution. The Robotic Stretch Wrapping Machine is decisive for the high quality appearance of your furniture. Machine comes with two standard spraying unit for perfected edgebanding applications , Anti-Adhesion and Polishing.

Cycle functions

The Robotic Stretch Wrapping Machine’s cycles can be activated through the control panel. The Robotic Stretch Wrapping Machine features various cycle options including an ascending and descending cycle, an ascending cycle only, a reinforce cycle at a programmed height (available in both ascending and ascending/descending cycles), an altimeter cycle to detect the pallet height and exclude the photocell, and a top sheet cycle (available in both ascending and descending options).

Additionally, the Robotic Stretch Wrapping Machine is equipped with a touch screen that allows for up to 10 programmable cycles to be configured according to the product and pallet being wrapped.

Technical Specifications

Voltage: 220 V – 60Hz.

- Study steel body

- Manual working mode

- Film carriage and turntable by transmission chain

- Machine controlled by PLC and color touch screen 7,2”

- Safety features

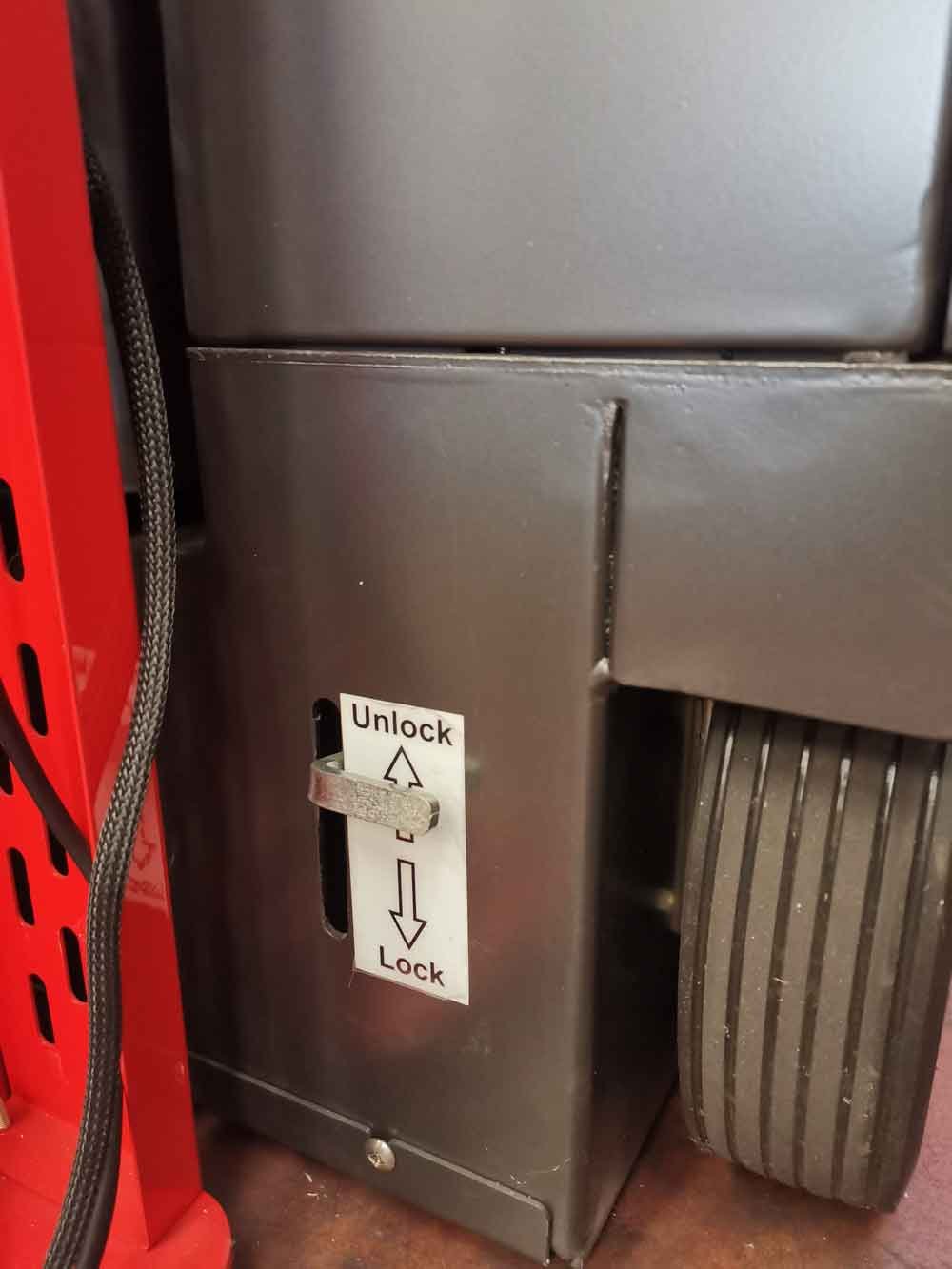

- Lock / unlock device for easy film hooking to the pallet

- Acoustic warning with light signal at the start cycle

- Film tensioning by mechanical brake (Easy Wrap 2000 A)

- Emergency stop

- Reset button

- Front and back holes for forklifting

- Inverter for soft start and indexed stop of the turntable

- Cycle counter

Parameters for wrapping recipe

- Define the turns at the start cycle

- Quantity of turns at the top of the pallet

- Number of turns at the bottom of the pallet (at the end of the cycle)

- Turn plate speed adjustment from 0 to 12 rpm

- Ascending / Descending carriage speed adjustment

- Customizable turntable indexing time

- Setting of photocell delay

Click here to see all Packaging Machines.