Description

Introducing to Automatic Wrapping Machine Arm Wrap

The Automatic Wrapping Machine Arm Wrap, also known as the Arm Wrap 2500B, is designed to stabilize pallets during wrapping by the rotating arm. It’s suitable for medium/high production and can handle unstable loads.

The Automatic Wrapping Machine Arm Wrap can be an independent unit or installed at the end of an automatic production line and comes with input/output pallet transport. It features a single motorized pre-stretch carriage with a fixed 200% ratio and the option to increase to 250% with 2 gear replacements. The touch-screen control unit offers high functionality, error detection, and manual functions.

The machine also has a film clamp, cutting and welding system, and optional accessories. It includes perimeter protections such as locking doors and safety barriers in entry/exit areas

Click here to see product info and learn price of the Automatic Wrapping Machine Arm Wrap.

Key Features

The Arm Wrap features a steel sheet frame that is painted for durability. The machine has a max height of 94.5″ (with a useful height of 78 3/4″) and can operate in environments with humidity levels up to 90% and temperatures ranging from 0° C to 40° C. The Automatic Wrapping Machine Arm Wrap is equipped with a film cut and clamp system, a temperature-controlled film welding system, and an arm with a diameter of 1700 mm.

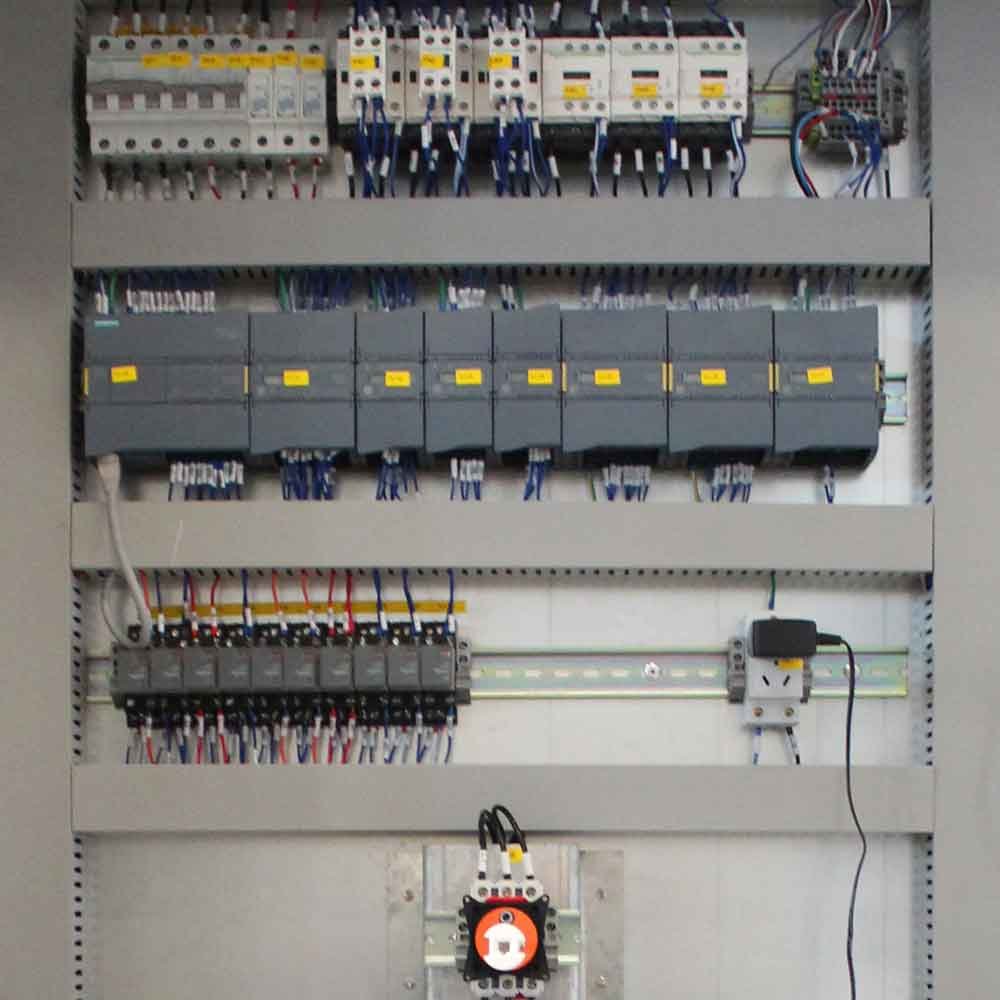

The conveyor height is 450 mm and can be customized upon request. The machine also includes a motorized pre-stretch system that can be adjusted between 150%, 200%, and 300% and an emergency stop in compliance with CE regulations. The machine is controlled by a PLC SIEMENS, which includes a film carriage fall protection system, an acoustic warning and lamp at the cycle start, an inverter “Schneider”, a 7.2″ user-friendly “Siemens” touch screen, contactors and buttons “Schneider” and sensors “P+F” Pepperl+fuchs.

Cycle functions

The Automatic Wrapping Machine Arm Wrap allows for manual operation, as well as programmed wrapping cycles including a cycle for ascending and descending, an “energy saving film mode,” a reinforce cycle, a top sheet cycle, and a total of 8 programmable wrapping cycles. With the option of manual operation, the Automatic Wrapping Machine Arm Wrap can be operated with a manual control of the film carriage, while the programmed cycles allow for automated and efficient wrapping of the load.

The energy saving film mode is a function that optimizes the use of film to reduce waste and improve efficiency. The reinforce cycle is for additional security of products that need extra protection and the top sheet cycle is for adding a top layer of film to the load. The 8 programmable wrapping cycles provide flexibility and can be customized to suit the needs of different products and loads.

Click here to see all Packaging Machines.