Description

Full Automatic Strapping Machines

We are providing largest selection for your box strapping machine needs with our customizable Italian solution partner isg-pack. We are dedicated to help you to wrap strong and tight while helping you to use less stretch film. Our Full Automatic Strapping Machines are not just helping you to save money also protecting the environment as well.Price for the wrapping machine can be provide by your consultant free , contact now .

The Easy Strap 309, a next-generation strapping machine, is designed to meet all your packaging strapping needs and can be operated by an operator. This machine employs DC motors to manage each of its functions, making it incredibly efficient. Unlike traditional strapping machines, the Full Automatic Strapping Machines eliminate over 30% of mechanical parts. It is a sturdy and compact machine that is highly effective for medium to high-volume workloads. Its 180° rotating control panel enables operation on both sides of the machine, while the strapping foot pedal initiates the working cycle. Additionally, it comes with a pneumatic top press option. Best practice to keep cardboard box together and stronger to strap or bundle them, full automatic line is a budged machine for middle to high volume applications.

As an option, the Full Automatic Strapping Machines’ bodies are also available in stainless steel best for where there is a high collisional material packaging or food products.

You can wrap your luggage, windows, door, profiles, extrusions, all size and heigh of skids, cabinets, furnitures, packages , bags w/o using a pallet. Stretch wrapping comes with a standard hight sensor however for black box material wrapping and special shapes you can upgrade your wrapping machine with a laser sensor as well.

We can provide two main model of the strapping machine one with 40 cycle per minutes and 60 cycle per min , please inform for the min / max material sizes and weight your sale consultant

Technical Features

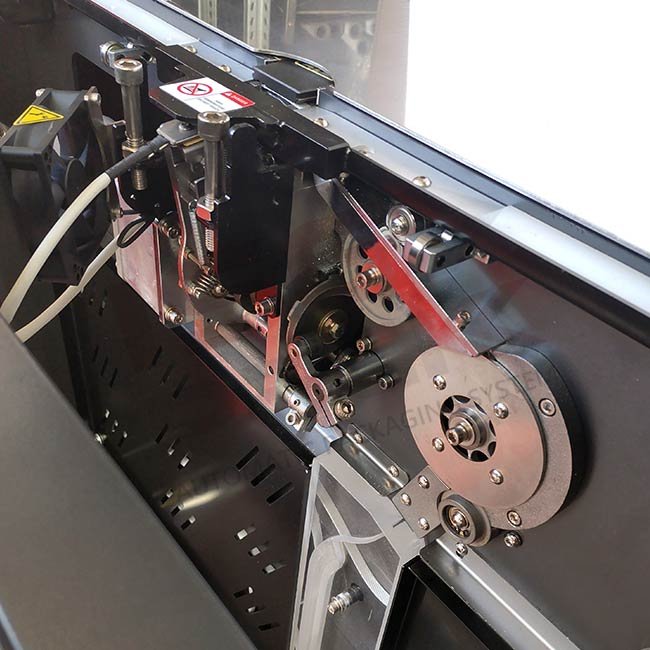

This is a description of a steel working table that is equipped with several safety features and a strapping group powered by DC motors. The table has a stainless steel safety handle and magnetic safety switches to ensure safe operation. The strapping group has an automatic strap loading system and a strap coil holder that can be unlocked by a button. It also includes a loop ejection system, and the 180° rotating analog control panel allows for easy operation from any angle. There is a strap cutter device for cutting the straps to the desired length.

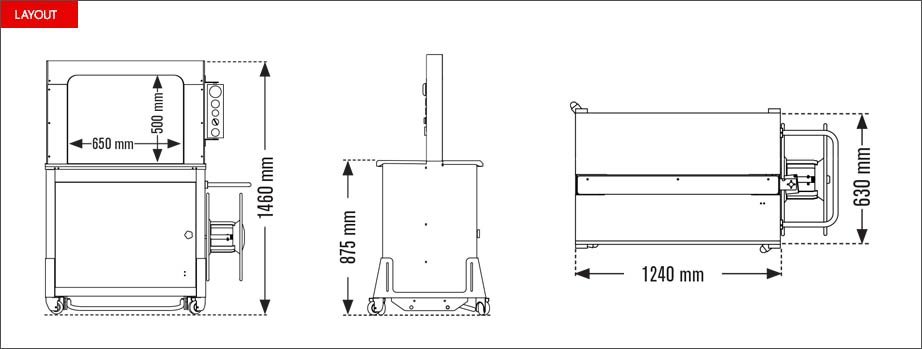

The working table height is adjustable, and it has four pivoting wheels, two of which have brakes. A strapping foot pedal is also included, along with an emergency stop button. At the end of the strap coil, there is an automatic strap ejection system and a re-feed strap system. The cooling time is adjustable, and there are various arches dimensions available. The strapping tension can be adjusted by a potentiometer.

Voltage: 115V or 220 V – 60Hz options are available

Click here to see product info and buy our full selection of packaging machines.

Key Features

- Min. Product dimensions: L 23.62″ x H 17 23/32″ . (with strapping arch L 25 18/32″ x H 19 11/16″)

- Product weight: 55 lbs

Cycle functions

The stretch wrapping machine’s cycles can be activated through the control panel. The machine features various cycle options including an ascending and descending cycle, an ascending cycle only, a reinforce cycle at a programmed height (available in both ascending and ascending/descending cycles), an altimeter cycle to detect the pallet height and exclude the photocell, and a top sheet cycle (available in both ascending and descending options). Additionally, the machine is equipped with a touch screen that allows for up to 10 programmable cycles to be configured according to the product and pallet being wrapped. Our Full Automatic Strapping Machines are compatible with American and European style skids.

Strap Roll Features

- Internal diameter: 7 7/8″

- External diameter: 15 3/4″ – 17 23/32″

- Strap width: 9 – 12 mm.

- Strap thickness: 0,45 – 0,65 mm.

- Strap type: PP (Polypropylene)

The Full Automatic Strapping Machines’ cycles can be activated through the control panel. The Full Automatic Strapping Machines feature various cycle options including an ascending and descending cycle, an ascending cycle only, a reinforce cycle at a programmed height (available in both ascending and ascending/descending cycles), an altimeter cycle to detect the pallet height and exclude the photocell, and a top sheet cycle (available in both ascending and descending options). Additionally, the Full Automatic Strapping Machines are equipped with a touch screen that allows for up to 10 programmable cycles to be configured according to the product and pallet being wrapped.

Click here to see all Packaging Machines.