Description

Introducing the Full Automatic Speed Strap 505B-509B-512B Strapping Machines: High-Performance Fully Automatic Strapping Machines

The Full Automatic Speed Strap 505B-509B-512B Strapping Machines, including models 505B, 509B, and 512B, represents the pinnacle of high-speed strapping technology. These Full Automatic Speed Strap 505B-509B-512B Strapping Machines are designed to seamlessly integrate into packaging lines, ensuring not only exceptional production rates but also unmatched reliability. Operating at an impressive speed of 50 cycles per minute, they offer a maximum adjustable tensioning force of up to 45 kg, catering to a wide range of strapping needs.

Technical Features

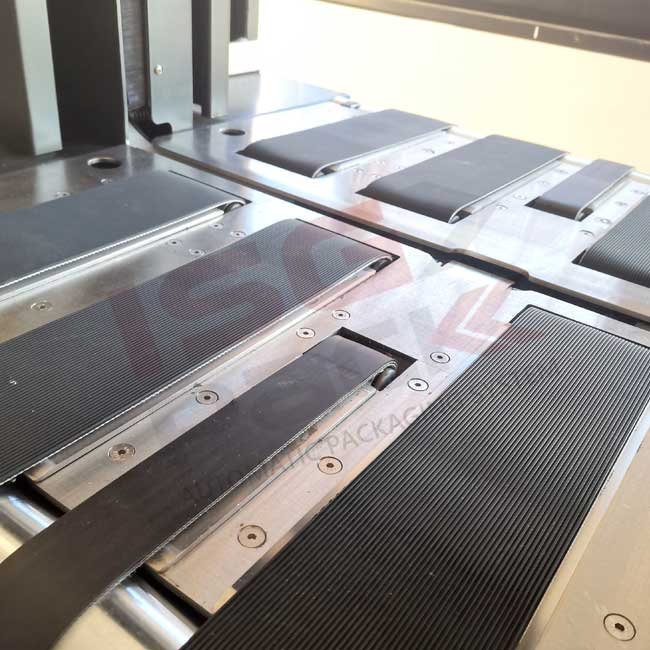

- Motorized Belt Conveyor: Equipped with a dynamic working table featuring motorized belt conveyors for seamless and efficient strapping.

- Stainless Steel Safety Handle: Designed with a durable stainless steel safety handle for secure operation.

- Safety Guards with Magnetic Switches: Ensures safety with magnetic safety switches on each door, enhancing operator protection.

- Automatic Strap Feeding: Offers automated strap feeding for continuous and smooth operation.

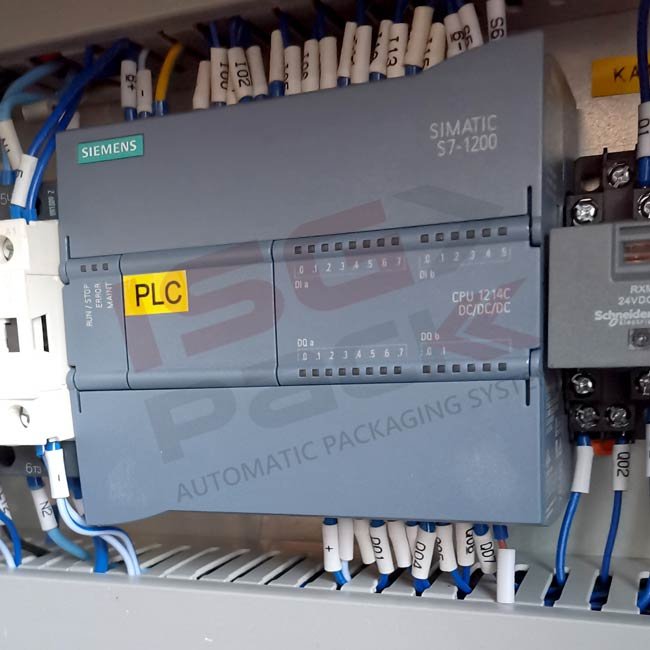

- Touch Screen Control: In & out signals are displayed on the intuitive 7.2’’ touch screen control panel for user-friendly interface.

- Precision Strapping Group: The strapping group is precision-controlled by 24V brushless motors, ensuring accuracy and reliability.

- Versatile Strapping Options: Capable of single, double, or multiple strappings, with the added flexibility of transit mode for non-product strapping.

- Adjustable Belt Speed: Belt speed is easily adjustable through the inverter, allowing customization based on specific strapping requirements.

- Visual and Audible Alerts: Provides acoustic and 3-color luminous signals for easy monitoring of strapping processes.

- Loop Ejection: Includes a loop ejection feature for efficient handling of strapping materials.

- Integrated Strap Cutter: Equipped with a strap cutter device for precise and clean cutting of straps.

- Height Adjustable Table: The working table height is adjustable, accommodating various product dimensions and sizes.

- Mobility: Features four pivoting wheels, two of which are equipped with brakes, ensuring easy mobility and stability during operation.

- Easyfast Strap Guide Disassembly: Incorporates the Easyfast strap guide disassembly system, allowing for quick disassembly without the need for additional tools.

- Automatic Strap Management: Automates strap ejection at the end of the coil and offers a re-feed strap system for uninterrupted operation.

- Strap Variety: Supports the use of various strap sizes, providing versatility for different packaging needs.

- Multiple Arch Sizes: Offers various arch dimensions, including L 650 x H 500 mm, L 850 x H 500 mm, L 850 x H 600 mm, and L 850 x H 800 mm, catering to diverse packaging requirements.

Click here to see product info and buy our full selection of packaging machines.

Key Features

-

- Efficient Integration: These Full Automatic Speed Strap 505B-509B-512B Strapping Machines are high-performance strapping machines engineered for automatic packaging lines, guaranteeing both high productivity and stringent reliability standards.

- Innovative Design: The Full Automatic Speed Strap 505B-509B-512B Strapping Machines feature 24V Vcc brushless motors for each function, coupled with an integrated working table equipped with 8 motorized conveyor belts. Among these, two smaller belts are strategically placed at the center, allowing secure strapping of even small-sized products.

- Automatic Operation: Photocells are strategically positioned at the entrance and exit points, enabling the machine to execute single, double, or multiple straps automatically. The Full Automatic Speed Strap 505B–509B–512B Strapping Machines also offer the option of a pneumatic stabilizing press and is available in a durable SUS 304 stainless steel version.

- User-Friendly Interface: The Full Automatic Speed Strap 505B-509B-512B Strapping Machines operate on a 220V power supply with adjustable worktop height (from 870 to 970 mm). Their user-friendly 7.2” touch screen control panel simplifies operation. Additionally, it includes features such as a 3-color flashing column, “mode transit” function for non-product strapping, and an Easyfast® strap guide disassembly system, eliminating the need for tools.

- Enhanced Customization: Tailor your strapping solution with options like automatic ejection of strap remnants, adjustable welding cooling time (COOL TIME), sealing blade temperature control, strap cutting cutter, automatic strap loading system, and magnetic safety sensors. The machine is available with various arch sizes, ensuring a perfect fit for diverse applications.

Experience unparalleled efficiency and reliability with the Full Automatic Speed Strap 505B-509B-512B Strapping Machines – your ideal choice for high-speed, fully automatic strapping solutions.

Strap Roll Features

- Internal Diameter: 200 mm

- External Diameter: 400 – 450 mm

- Strap Width Options: 5 – 9 – 12 mm

- Strap Thickness Range: 0.45 – 0.65 mm

- Strap Type: PP (Polypropylene)

The stretch wrapping machine’s cycles can be activated through the control panel. The machine features various cycle options including an ascending and descending cycle, an ascending cycle only, a reinforce cycle at a programmed height (available in both ascending and ascending/descending cycles), an altimeter cycle to detect the pallet height and exclude the photocell, and a top sheet cycle (available in both ascending and descending options). Additionally, the machine is equipped with a touch screen that allows for up to 10 programmable cycles to be configured according to the product and pallet being wrapped.

Click here to see all Packaging Machines.