Description

Press brakes, also known as brake presses, bending machines, sheet metal brakes, metal press brakes, hydraulic press brakes, CNC press brakes, plate bending machines, and metal folding machines, are used for shaping and bending sheet metal.

Servo Electric Press Brakes are no-hydraulic, flexible, reliable and advance bending machines. A next generation machine idea that combines green-Eco friendly machines productivity, accuracy, flexibility and reliability. The new concept offers low energy consumption, less maintenance, without hydraulic oil for operation.

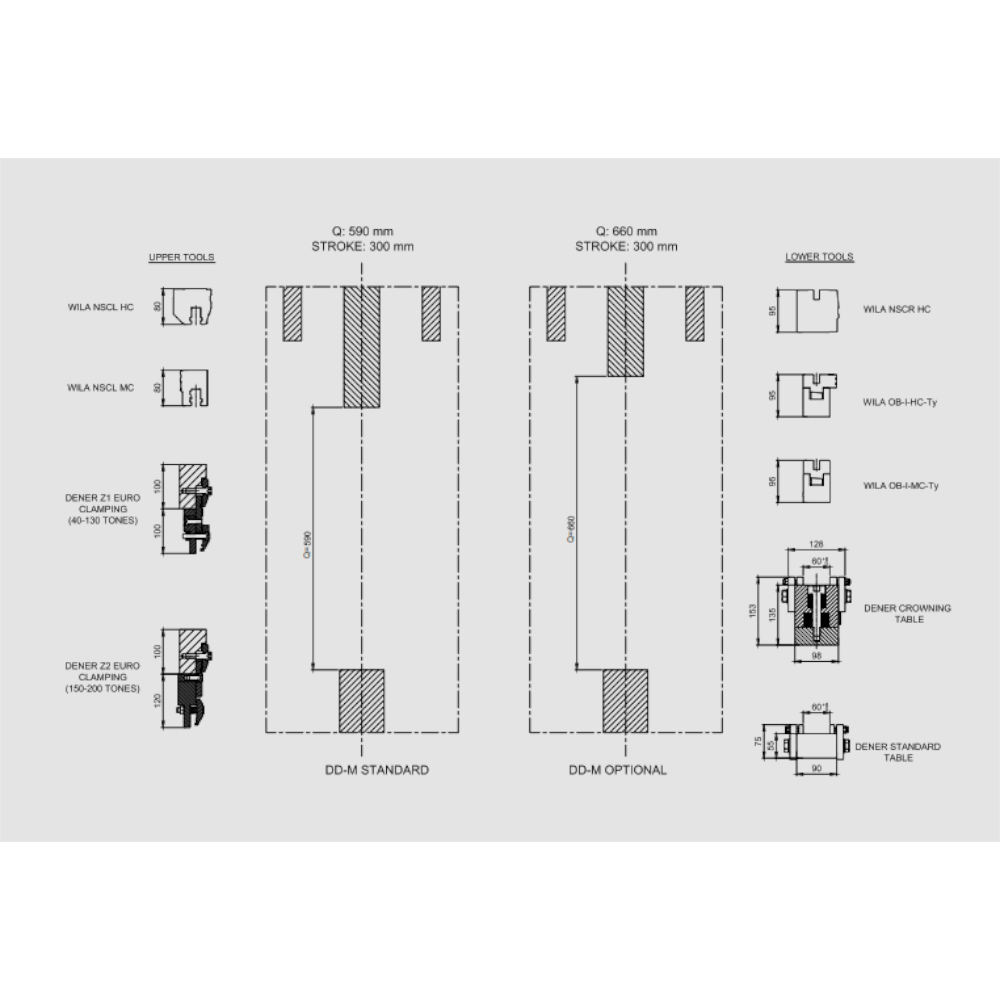

Press Brakes come with an advance CNC controller, fast and accurate puncher and die clamping and a multi axis back gauge system. Making sheet metal bending at lowest possible cost is very easy.

AKK machinery a chinese fabricator since 2004 providing high quality and continuous press brake Servo Electric Press Brakes are %100 Pure electric power machines. Up to %50 less energy consumption compared to a hydraulic press brake. Up to %35 faster compared to a hydraulic press brake. High efficiency and precision. High bending speed and less noise. Full bending length between side frames. Less maintenance cost. Eco friendly. Friendly user interface. Auto bending step calculation for STEP and DXF files.

on previous years press brakes mostly used on the number of fabricators for heavier gauge metal bending , since the industrial development and competitive pricing in the market today even light gauge fabricators who uses gauge 12 to 18 galvanized ,thinner stainless steel or aluminum , they start choosing the press brakes as they can achieve perfect result with lesser time than folding or bending machines.

See all our Press Brakes