Description

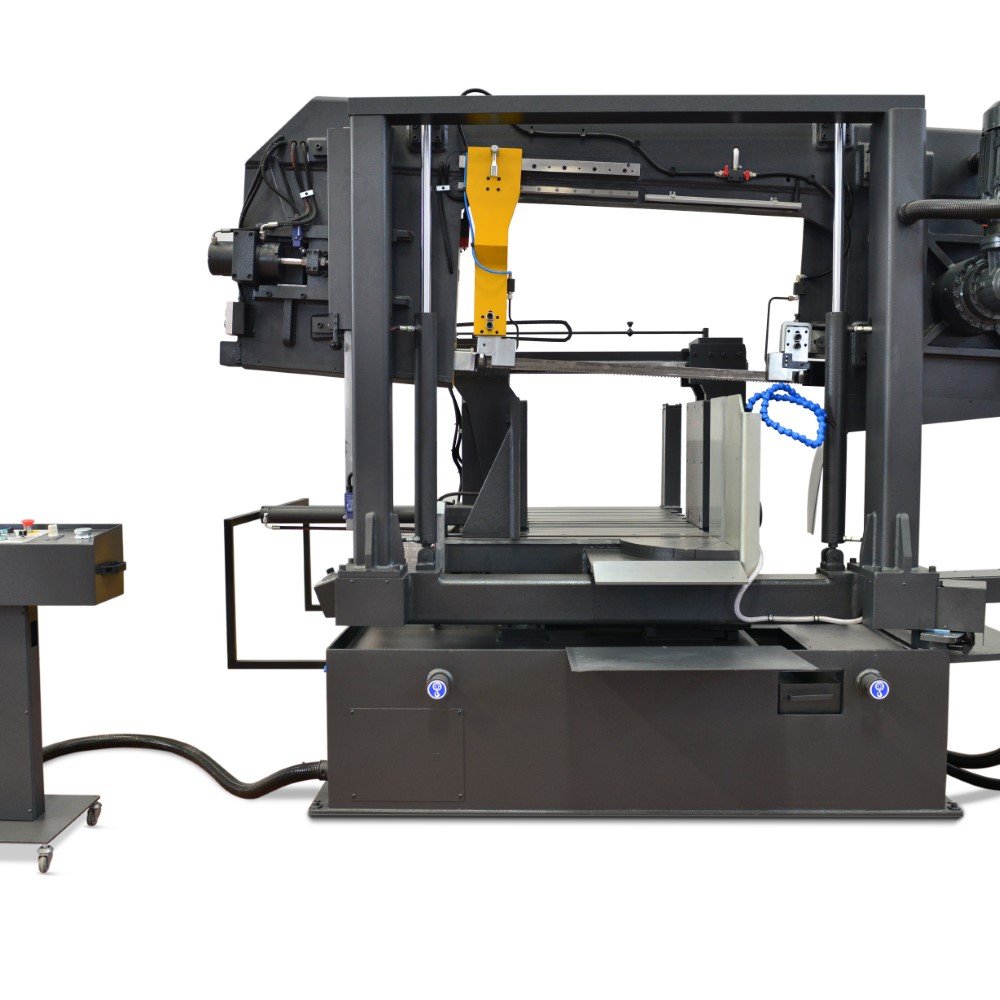

The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-540CGS NC is an advanced metal cutting solution designed for precision mitre cuts in varied quantities. Built with linear guideways and a fully automated control system, the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-540CGS NC is capable of delivering consistent and accurate cuts with high efficiency. The machine allows bow movement between 30 and 90 degrees, providing flexible cutting angles to meet different project requirements.

The Fully Automatic CGH Mitre Twin Pillar Saw BMSO-540CGS NC features the ability to store up to 30 cutting programs, each with 50 programmable cutting steps, including length and quantity data. All adjustments are input through the PLC control panel, and measurements are taken using a digital ruler for exceptional accuracy. Stroke-based measurement repeats according to a 27 9/16″ (700mm) length, ensuring precision during long cutting sequences.

One of the standout features of the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-540CGS NC is its hydraulic cutting control system. After each cut, the machine’s bow automatically lifts to the material height, reducing idle time and improving workflow. The cutting capacity at 90 degrees reaches 21 1/4″ x 26 3/8″ for rectangular sections and 21 1/4″ in diameter for round materials. An automatic height sensor allows the bow to quickly approach the material and ensures smooth engagement.

Safety is a key focus of this machine. Mechanical switches, a hydraulic brake system for bow angle locking, and a secondary digital counter on the main body ensure operational control and operator safety. Like all Bekamak products the Fully Automatic CGH Mitre Twin Pillar Saw BMSO-540CGS NC integrates robust mechanical and electrical safeguards for reliable industrial use, especially in demanding metalworking environments.

Click here to see all twin pillar saws.