Description

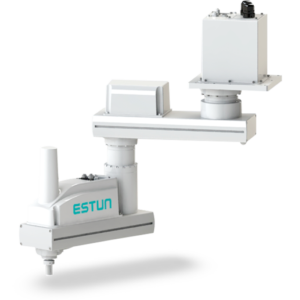

Sheet metal bending robot design to to handle most difficult bending task to handle easily.

It has direct contact with Delem DA 66T 3D controller

Offline programming: Offline programming uses some sensors, mainly relying on computer graphics technology, establishing a working mode, and performing three-dimensional graphics animation simulation on the programming results to detect the reliability of programming, and finally pass the generated code to the industrial robot control cabinet to control the operation of the robot. In the offline state, write a program with a text editor, and then load it on the robot controller to run. It helps you reduce downtime, accelerates robot system integration, and can continuously edit and improve robot programs without affecting production efficiency.

Machine can also work with other controller unit in analog or digital mode,

In the analog signal mode, the bending machine CNC system and the bending robot need to convert signals in order to communicate with each other. In the process, data may be lost or interfered (such as electromagnetic interference). Under the direct communication mode between the CNC system and the robot, this simulation signal conversion link is missing, so it is more stable and the response speed is faster