Description

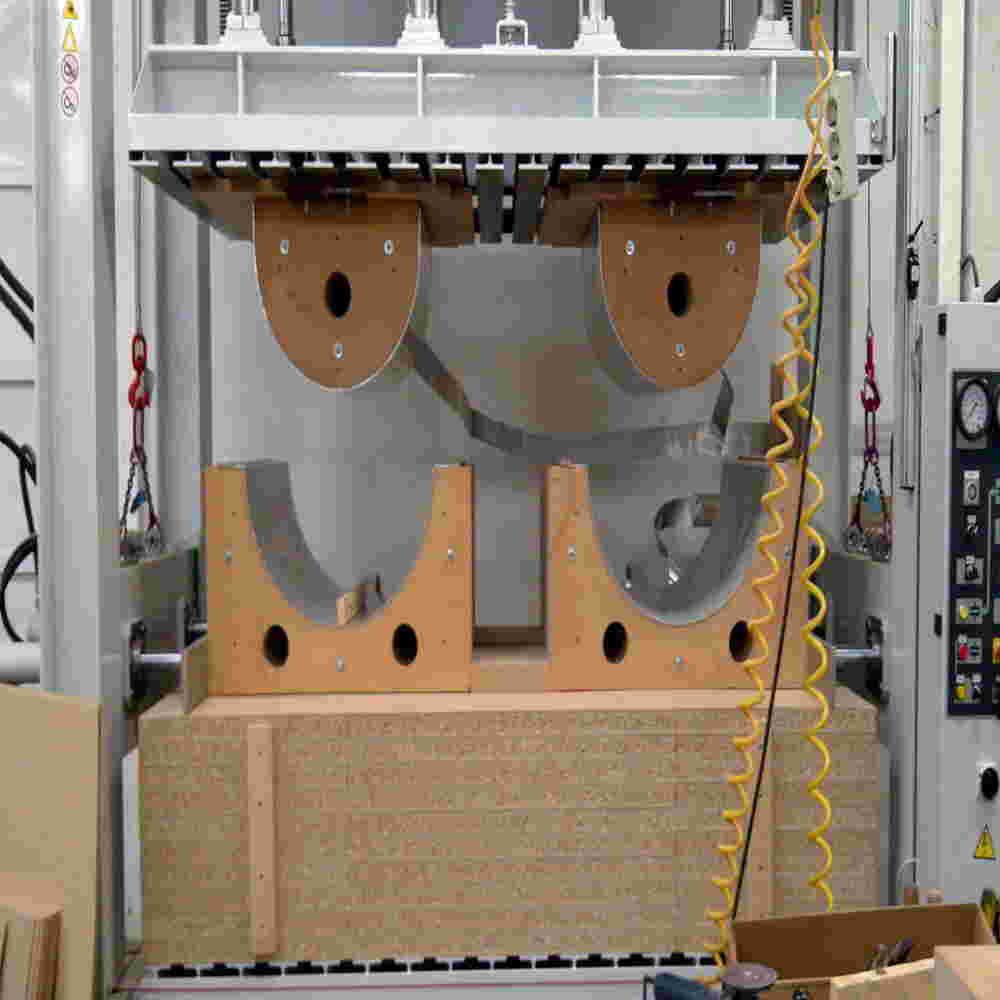

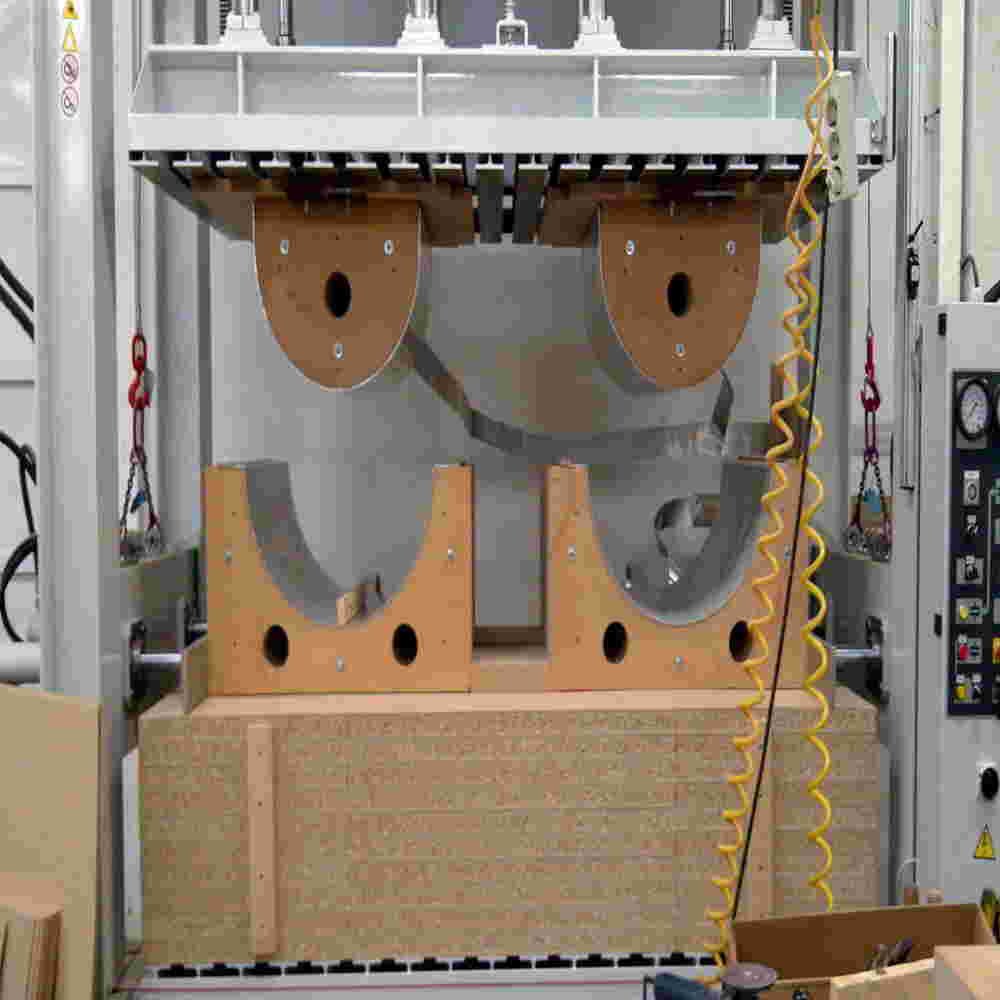

Composite Panel Presses are essential machines widely used in the furniture industry, particularly for cold pressing and shaping wood components. One of the most common applications of Composite Panel Presses is wood bending, which is critical for producing curved or contoured furniture elements. These presses can be configured in multiple ways to meet the specific needs of each production line–whether you’re bending multi-layer plywood, solid wood, or preparing wood through moistening in a steam tank.

The Composite Panel Presses come equipped with user-friendly control panels and flexible table sizes. Pressures, platen dimensions, and additional equipment are all customizable based on your requirements. Whether you need a length from 63″ to 98.4″ or different press capacities, our engineering team works with you to build the ideal machine configuration for your production needs.

The system features a welded profile structure, upward-moving platens guided by racks and toothed wheels, and precision-machined beams with customizable gaps for mold fixing. Composite Panel Presses are driven by hydraulic cylinders engineered using proprietary designs, with high-quality, globally-sourced, fully replaceable seals. Alternative versions and custom requests are always available upon consultation.

TECHNICAL DATA

- Tables sizes: 1600×800 mm.

- Tables sizes: 2000/2500×1000 mm.

- Nr. cylinders: 4 / 6

- Ø cylinders: 70-85 mm.

Different versions and sizes are always available on request.

Options

Quantity of Cylinders

Power

Size

Please contact us to lean more about the availability and options:

Get Your Free estimate for Composite Panel Presses Today

Get Your Free estimate for planer Today

All press options are available at the link below

Click here to see all Woodworking Machinery