Description

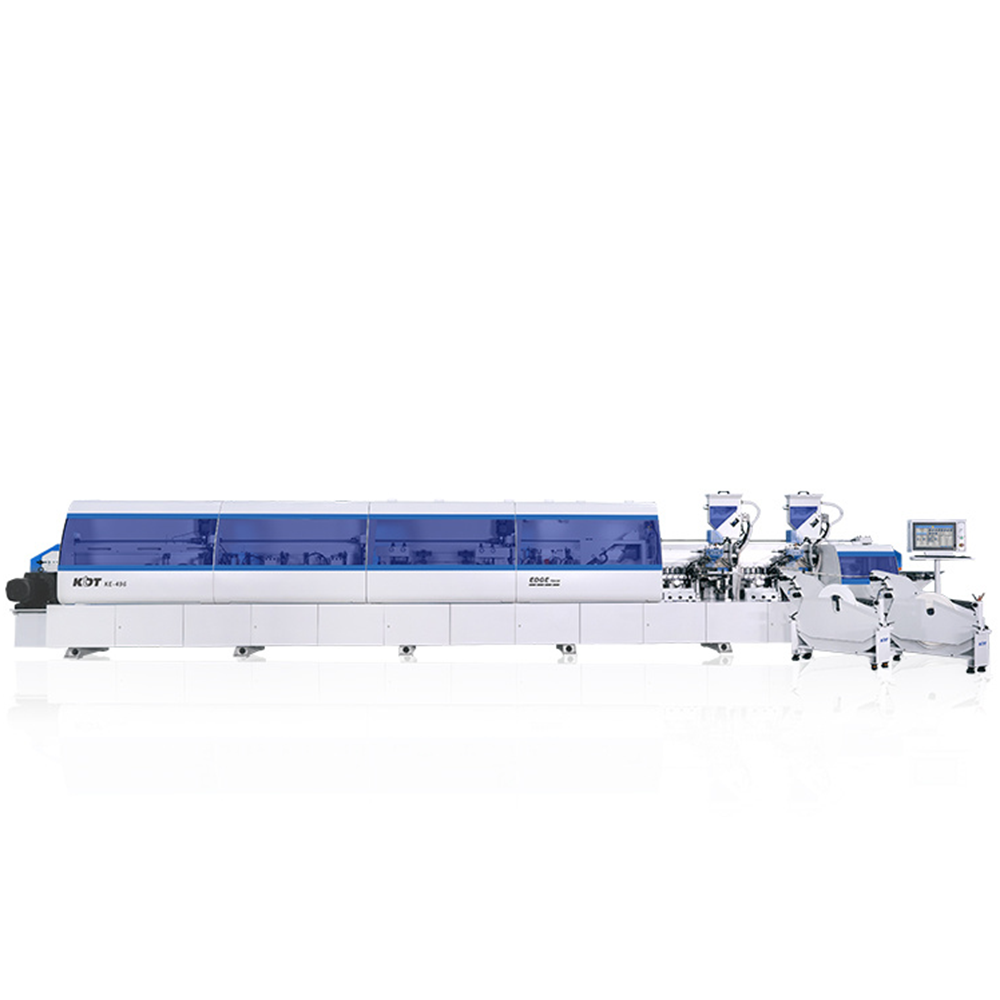

Double Up-Gluing Unit KE-496G: Elevating Edge Bonding Efficiency

Operating at a velocity of 26 meters per minute, the KE-496G Double Up-Gluing Unit enhances edge bonding through a dual adhesive application process. With the inclusion of a dual guide rail high-speed tracking system, this unit not only optimizes performance but also records operational data in real-time.

Product Advantages:

Revolutionizing High-Speed Edge Banding with KE-496G

- Incorporating a standard 40mm pre-milling mechanism, this unit adeptly refines the edge bonding surface of the panel. The result is a tighter fit between the edge banding strip and the panel, elevating both structural integrity and visual appeal.

- For tailored production demands, the optional PUR device facilitates swift transitions between two distinct adhesives, catering to diverse edge banding requirements.

- The automated adhesive dispensing mechanism, capable of storing up to 12.5kg of high-capacity adhesive particles, ensures timely supply for uninterrupted equipment operation.

EDGE TECH Elevating Agility and Intelligent Manufacturing As a renowned trailblazer in the realm of edge banding technology, we hold meticulous attention to every detail. Our commitment to innovation and research and development is unwavering. Aligned with customer needs, KDT continuously introduces cutting-edge international technologies and integrates key components from industry-leading brands. Our mission is to furnish global clientele with top-tier, precision-engineered products.

Comprehensive Smart Home Furniture Production Solution

Technical Parameters:

Model: KE-496G

Feeding Speed (m/min): 20-26

Tape Thickness (mm): 0.4-3

Panel Thickness (mm): 9-60

Panel Length (mm): ≥120

Panel Width (mm): ≥60

Minimum Panel Size (mm): 12060

Total Power (kW): 33.54

Overall Size (LxWxH, mm): 11315L990W1960H

Size & Quantity of Dust Hood: Ø12510

Hi, how can I help?

Hi, how can I help?