Description

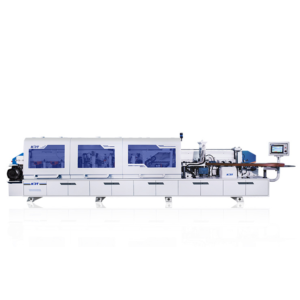

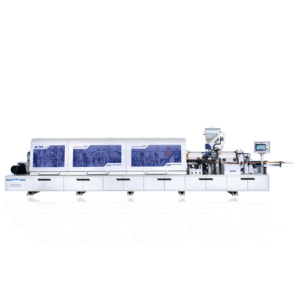

Pneumatic End Cutting Device – KE-655JS

Refined Cutting with Pneumatic End Cutter

Advantages of the Product:

- Equipped with a 10-inch touch screen featuring intelligent temperature control. The heat preservation function can be tailored, automatically transitioning to a heat preservation state when the machine operates without material. This enhances energy efficiency, reduces glue carbonization, and promotes high-efficiency operation.

- Incorporates a large-diameter diamond cutter head, offering a maximum pre-milling height of 40mm (optionally 65mm). Dual milling cutters effectively eliminate surface irregularities, burrs, or non-perpendicular issues arising from the cutting process. This ensures improved adherence between the edge banding strip and the board, resulting in a seamless fit, enhanced integrity, and aesthetic appeal.

- Preheats the board to facilitate better glue adhesion. Instant heating upon contact reduces energy consumption and enhances the effectiveness of edge sealing.

Edge Technology (EDGE TECH)

Enabling Flexibility and Intelligent Production As a renowned pioneer in the field of edge banding, we prioritize intricate details and are dedicated to continuous innovation and research and development. In line with customer requirements, KDT has consistently introduced cutting-edge international technology and integrated key components from leading brands. Our objective is to provide customers worldwide with top-quality products. A Comprehensive Solution for Intelligent Home Furniture Production

Technical Specifications

Model: KE-655JS

Feeding Speed: 15-23 meters per minute

Tape Thickness: 0.4-3 millimeters

Panel Thickness: 9-60 millimeters

Panel Length: ≥120 millimeters

Panel Width: ≥90 millimeters

Minimum Panel Size: 120mm x 90mm

Total Power: 19.05 kilowatts

Overall Dimensions: 5346mm (Length) x 830mm (Width) x 1700mm (Height)

Dust Hood Size & Quantity: Two hoods with diameters of Ø100 and two hoods with diameters of Ø125.