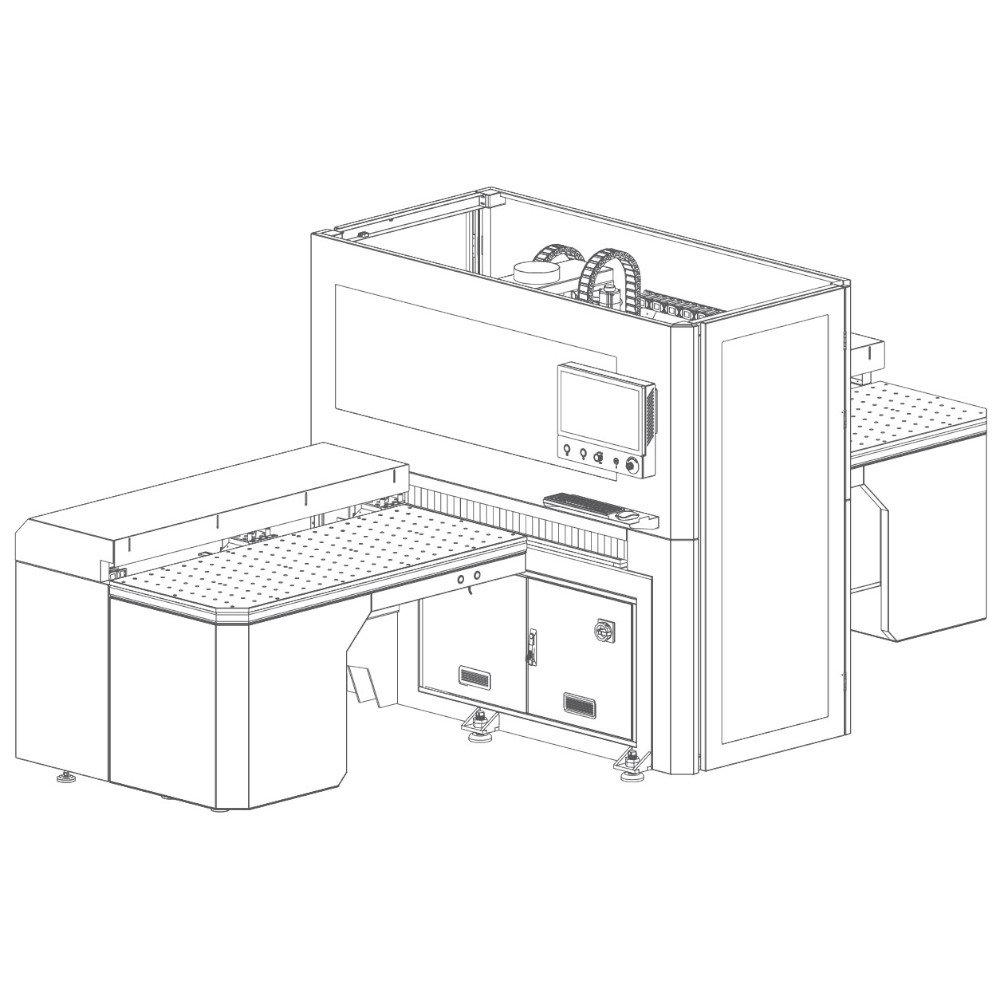

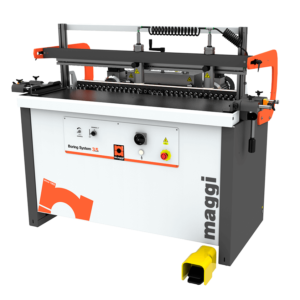

Description

Custom CNC Drilling Combinations

CNC Drilling Combinations can be arrange specifically for the need of fabricator. We create special drilling applications for excellent results. Standard air colling system give you piece of mind long work hours.

CNC Drilling Machine, In your modular applications with CEO CNC boring machines Quickly reach practical solutions. Italian TPA software specially designed for CNC drilling machines is used. CAD / CAM modules in this software, grooving, drilling, surface treatment, etc. allows you to easily design and program milling operations. All drilling applications can be performed with the custom boring unit, horizontal and vertical drills and grooving applications.

Accurate and Consistent

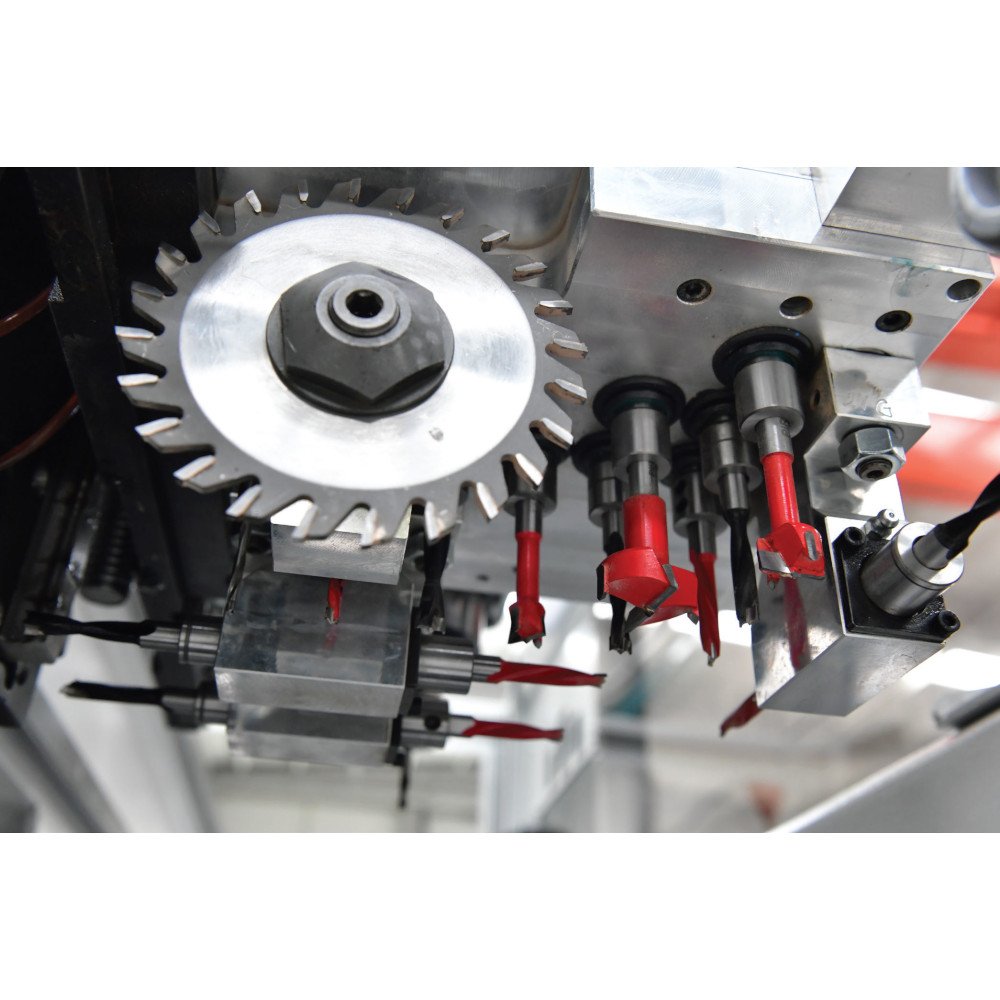

Grippers controlled by servo motors, it allows to carry out your workpiece handling and positioning operations with accuracy and consistency. The multi-drill unit can be used to drill all panel surfaces. Cutting and channeling operations are carried out quickly with the saw.

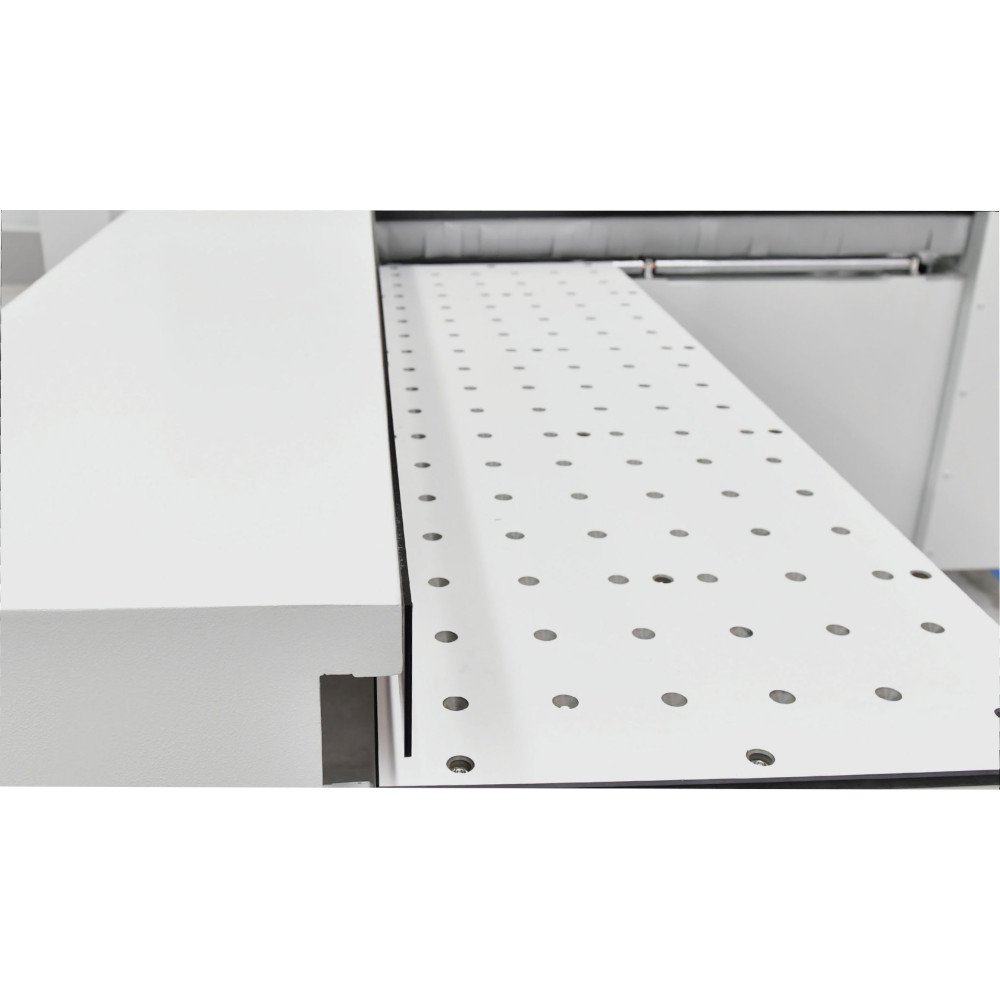

Air table type is preferred in CEO series. In this way, it gives the ability to be processed quickly and easily on the machine without damaging your workpiece. Thanks to its spindle motor, it allows you to perform grooving, hole drilling, surface processing, edge and corner cutting operations.

Best with this key features:

High Precision Machined Helical Rack and Guide Rail

Central Lubrication System

Part Positioning with Double Holder

For Milling Operations Spindle Motor Usage

German Kremayer and Rails

Fully Compatible Control Unit

Multi Drill and Saw Unit

Options

10 Vertical, 3 x 2 Horizontal – 1 saw group

32 mm center Hole distance

10 mm tool diameters

Click here to see all drilling machines.

AES CNC drilling machines , elfamak, omaksan, krc, hasmak, mutlucam proud dealer in North America. SCM drilling, biesse cnc drilling machines , holz-er or homag they are not well match candidates to beat up CEO

Cnc drilling machine, affordable drilling machine, best drilling machine, canada, toronto, moon machinery