Description

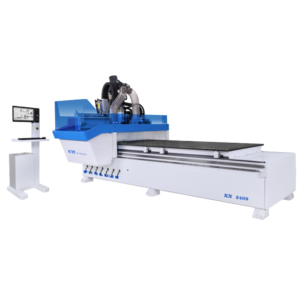

Pod and Rail Cnc router with five working axis is giving door and custom millworks the flexibility and accuracy they need for any type of milling, cutting and drilling on the 6 side of the product.

Key Features:

- Processing area 5150x1500x200 mm;

- Table type: Movable traverses “SCHMALZ”;

- Spindle: HSD (Italy) – 12 kW for HSK-63F chucks;

- Drilling and filler group: 12V+8H+1S;

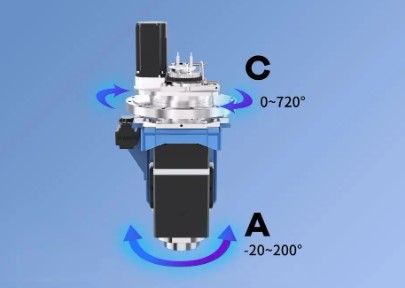

- 4th axis – C (0 – +720°);

- 5th axis – A (-20° – +200°);

- Servo motors for moving the gantry and spindle along the X/Y/Z axes: – 1/0.5/1 kW;

- Movement speed along the X/Y/Z axes: – 48/48/15 m/min;

- The mechanism of automatic tool change of revolving type for 22 tools + linear for 5 positions;

- Control rack OSAI (Italy) in Russian;

- The conveyor for removal of shaving installed in a basic complete set of the machine;

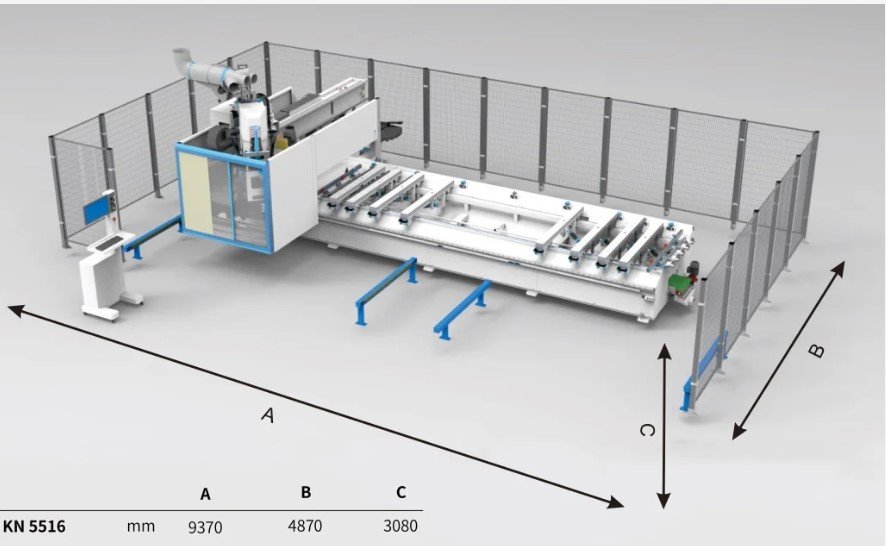

Technical Specifications:

-

Control system OSAI (Italy) Table size, mm 5150×1500 Spindle HSD, 12 kW, 24000 rpm, for HSK-63F clamp 4th axis C HSD (0 – +720°) 5th axis A HSD (-20° – +200°) drilling head 12 vertical + 8 horizontal spindles (4500 rpm) + 125 mm grooving saw (5400 rpm) Tool change revolving for 22 places + linear for 5 places Maximum tool diameter, mm 240 Maximum tool length (excluding workpiece height), mm 200 Moving speed A/C axes, °/s 40 Travel speed in X/Y/Z, m/min 48/48/15 Servo power in X/Y/Z, kW 1/0.5/1 Table configuration 8 vacuum traverses, SCHMALZ suction cups Total power consumption, kW 29,2 Productivity of vacuum pumps, m3/hour 1×244 Overall dimensions LxWxH, mm 7830x4365x3100 Weight, kg 5000